Special hoisting tool for bundled aluminum ingots

A technology for hoisting tools and aluminum ingots, which is applied in the direction of transportation, packaging, and load hanging components, etc., and can solve problems such as insufficient resource utilization, waste of space, and unsuitable hoisting of bundled aluminum ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

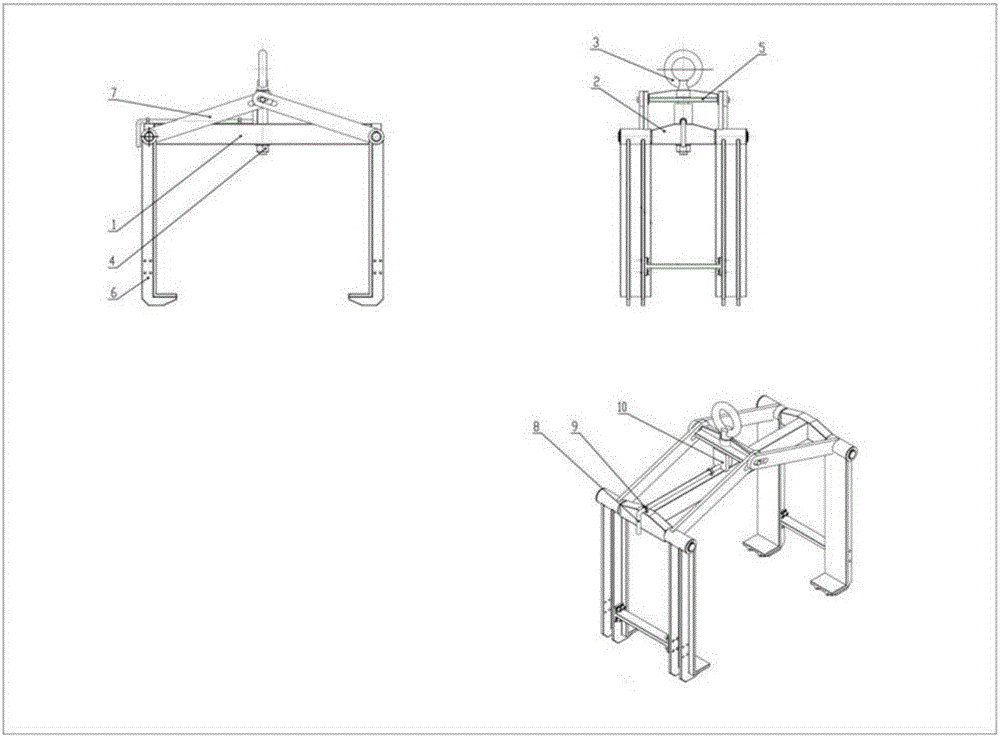

[0006] The technical solution of the patent of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. figure 1 It is a structural schematic diagram of the special spreader provided by the specific embodiment of the patent of the present invention. As shown in the figure, the hoisting tool is manually operated, and consists of the main load-bearing beam 1, the auxiliary load-bearing beam 2, the lifting ring 3, the lock nut 4, the interlocking support plate 5, the lifting hook 6, the movable lever 7, the pull rod 8, the fixed sleeve 9 and support plate 10 to form. The main load-bearing beam 1 is provided with a central mounting threaded hole; the suspension ring 3 is composed of a lifting hole and a suspension ring shaft, and the front end of the suspension ring shaft is an external thread, which is connected with the main load-bearing beam through the central mounting threaded hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com