Large steel casting of G17CrMo9-10 material and production method thereof

A production method and technology for steel castings, which are applied to large steel castings and their production fields, can solve the problems of tonnage, large wall thickness, unstable mechanical properties, and excessive hardness control deviation of the body, and achieve improved strength and excellent performance. , the effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

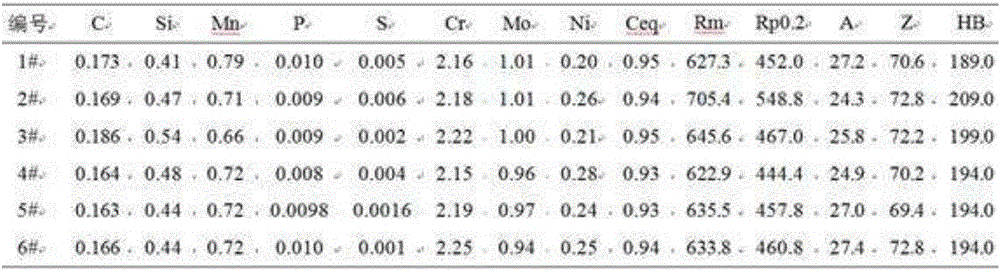

[0018] The embodiment of the present invention provides a large-scale steel casting of G17CrMo9-10 material. The chemical composition of the large-scale steel casting of G17CrMo9-10 material is C: 0.13 to 0.20%, Si ≤ 0.60%, and Mn: 0.50 to 0.90 %, S≤0.020%, P≤0.020%, Cr: 2.00~2.50%, Mo: 0.9~1.20%, Ni: 0.2~0.4%, V <0.05%, Cu <0.3%, the balance is iron.

[0019] Further, the chemical composition of the large-scale steel castings of the G17CrMo9-10 material is C: 0.16~0.19%, Si: 0.30~0.50%, Mn: 0.60~0.85%, S≤0.015%, P≤0.019%, Cr : 2.15~2.45%, Mo: 0.92~1.10%, Ni: 0.2~0.4%, V <0.05%, Cu <0.3%, the balance is iron.

[0020] The invention adds Ni element to the conventional low-alloy steel castings, thereby greatly improving the strength of the castings, and when the steel castings are quenched during the preparation process, the addition of Ni can improve the hardenability of the castings , Which makes the performance of the castings after quenching excellent.

[0021] The present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap