Multi-layer nest and coaxial sequencing assembly type anchor cable construction and installation method

An assembled and anchor cable technology, which is applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of damaged anchor cable components, frequent occurrence of cable jamming, and long size, so as to improve reliability and ensure smooth operation The effect of pushing and avoiding the phenomenon of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

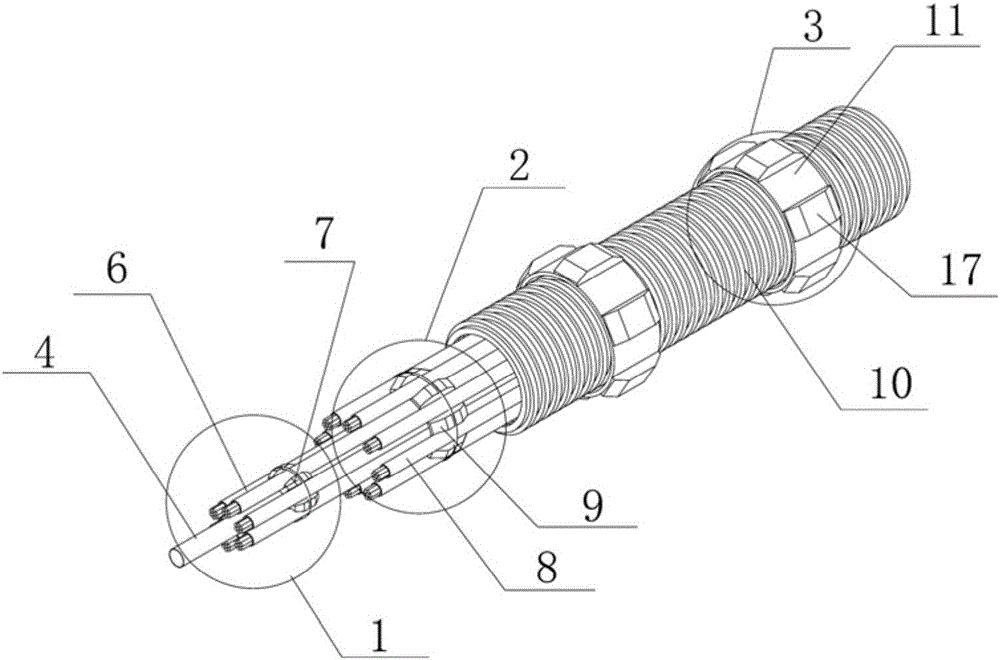

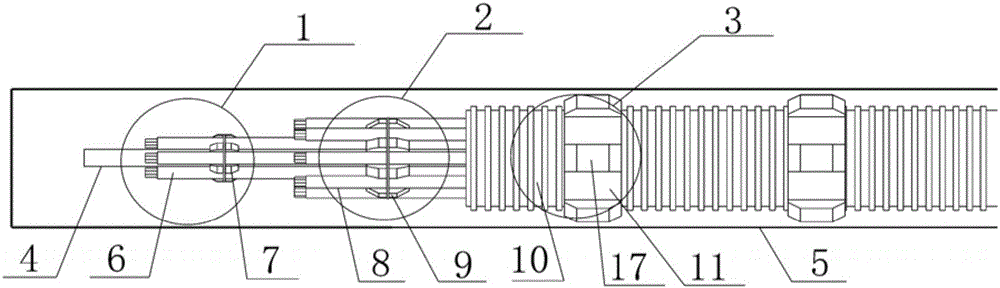

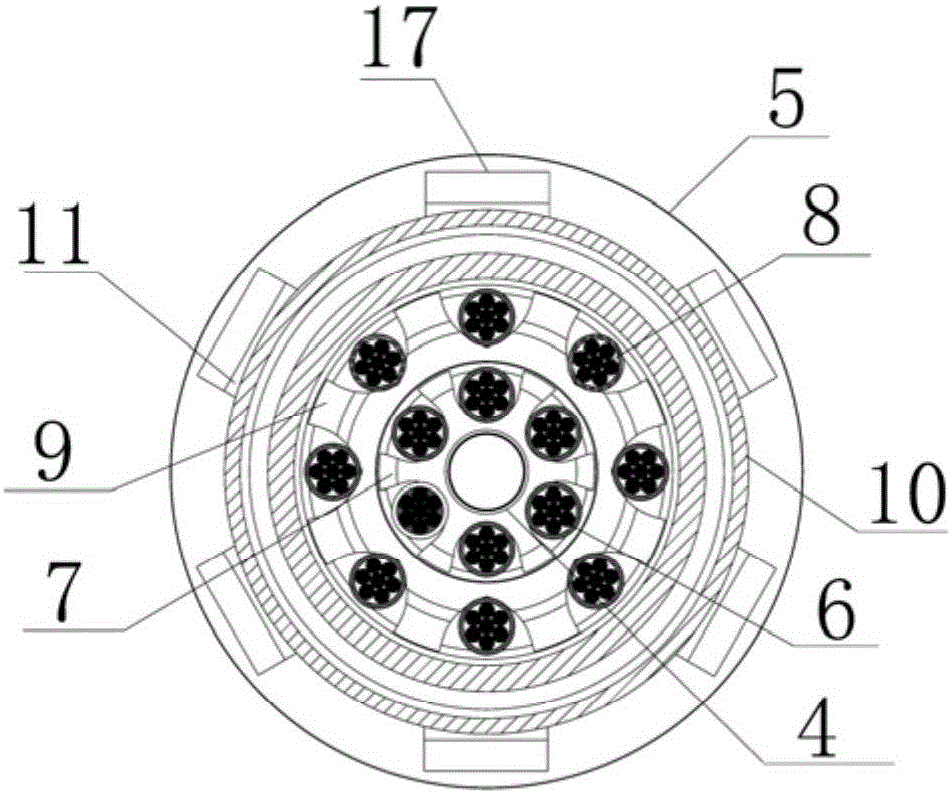

[0061] refer to Figure 1 to Figure 12 , The multi-layer nested, coaxial sequentially assembled anchor cable structure of the present invention includes an axial core layer 1, a middle frame layer 2 and an outer cladding layer 3 from the inside to the outside.

[0062] The axial layer 1 is located at the core of the overall structure of the anchor cable, including a grouting pipe 4 in the center and six inner ring anchor cable bundles 6 arranged around the grout pipe 4. Support 7 is fixed. The inner isolation bracket 7 is made of hard plastic, and its shape is similar to a ring structure of a gear. For ease of description, the gear term is used to describe below: the outer diameter of the gear is 70mm, the inner diameter of the gear is 27mm, and the tooth width i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com