Entirely prefabricated monolayer steel plate-concrete composite shear wall and assembly method thereof

A combined shear wall and integral prefabrication technology, applied in the processing of walls, building materials, building components, etc., can solve the problem of high labor intensity in the construction of shear steel plates and steel mesh, poor installation accuracy of steel mesh, and difficulty in guaranteeing project quality, etc. problems, to achieve the effect of improving the level of on-site safe and civilized construction, ensuring the quality of the project, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

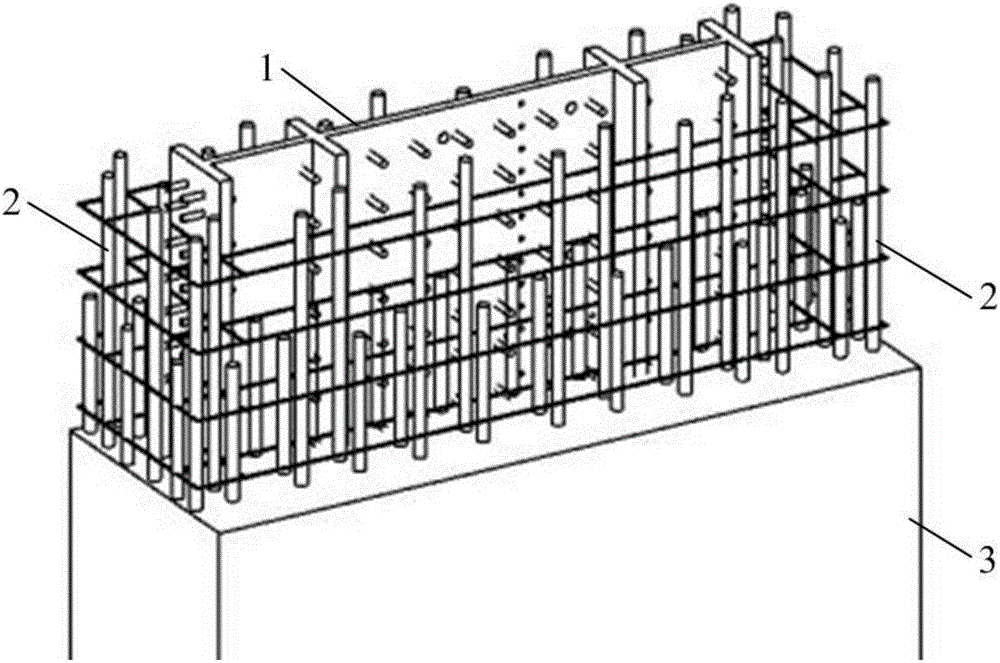

[0025] Example 1: Combining Figure 7 Illustrate the integrally prefabricated single-layer steel plate-concrete composite shear wall 100 of the present invention, which includes several sections of shear steel plates 10 connected together, a reinforcement mesh 20 enclosed outside the shear steel plates 10 and affixed to the shear steel plates 10 and the concrete layer 70 covering the shear steel plate 10 and the steel mesh 20; the above-mentioned steel mesh 20 includes a side-standing reinforcement mesh one 21 and a side-standing reinforcement mesh two 22 positioned at the shear steel plate 10 both sides, and the side-standing reinforcement mesh one 21 and side-standing steel mesh two 22 are integral prefabricated processing.

[0026] The overall prefabricated single-layer steel plate-concrete composite shear wall 100 is assembled from the shear steel plate 10 and the side-standing reinforcement mesh 1 21 and the side-standing reinforcement mesh 2 22 on both sides thereof. Bo...

Embodiment 2

[0031] Embodiment 2: Combination Figure 2 to Figure 7 Illustrate the assembling method of the integrally prefabricated single-layer steel plate-concrete composite shear wall of the present invention, concrete steps are as follows:

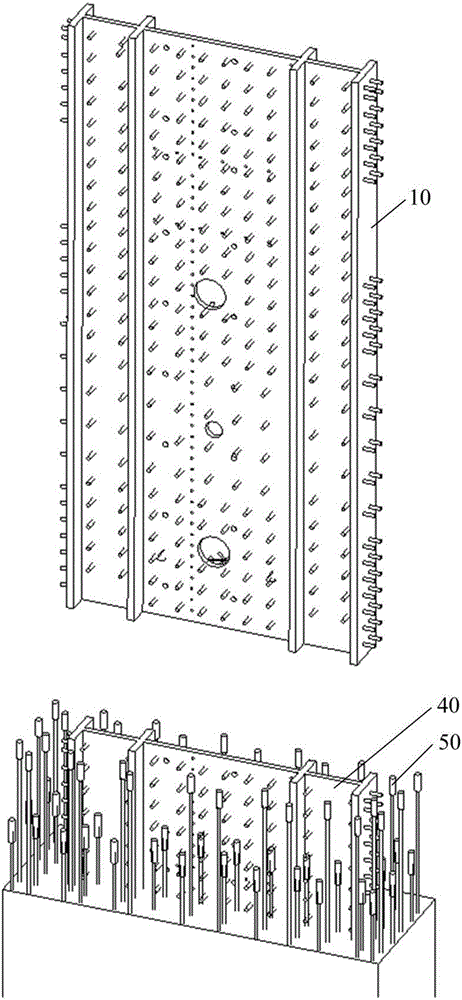

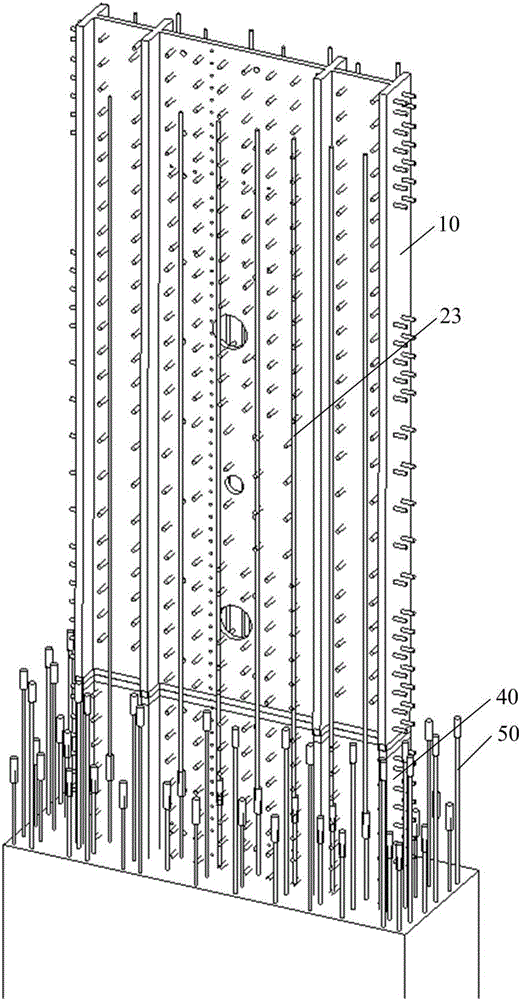

[0032] One, such as figure 2 with image 3 As shown, the shear steel plate 10 is hoisted, and the shear steel plate 10 and the reserved shear steel plate 40 are horizontally connected;

[0033] Two, if Figure 4 to Figure 6 As shown, the prefabricated side-standing reinforcement mesh 1 21 and side-standing reinforcement mesh 2 22 are hoisted respectively, so that the side-standing reinforcement mesh 1 21 and the side-standing reinforcement mesh 2 22 are respectively arranged on both sides of the shear steel plate 10, and the side-standing reinforcement Mesh 1 21 and side-standing reinforcement mesh 2 22 are respectively connected with the reserved reinforcement mesh 50 and the shear steel plate 10, thereby forming a fixedly integrated shear st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com