Ultrasonic phased array automatic detection device for steel large-sized vertical type storage tank

An ultrasonic phased array, automatic detection technology, applied in the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves, can solve the problems of low detection efficiency, high labor intensity, long cycle, etc., and achieves simple operation and maintenance. The effect of ensuring project quality and avoiding radiation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

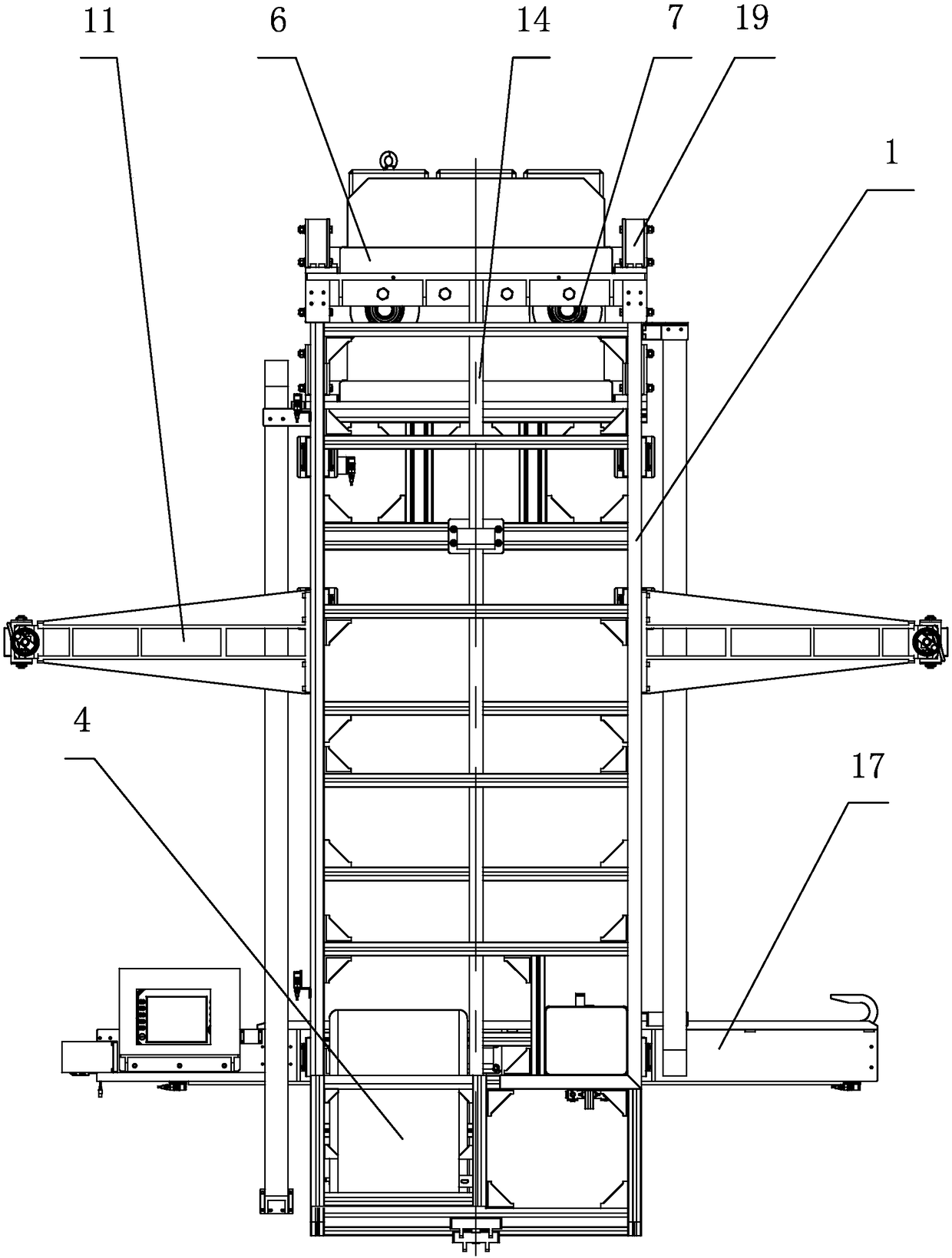

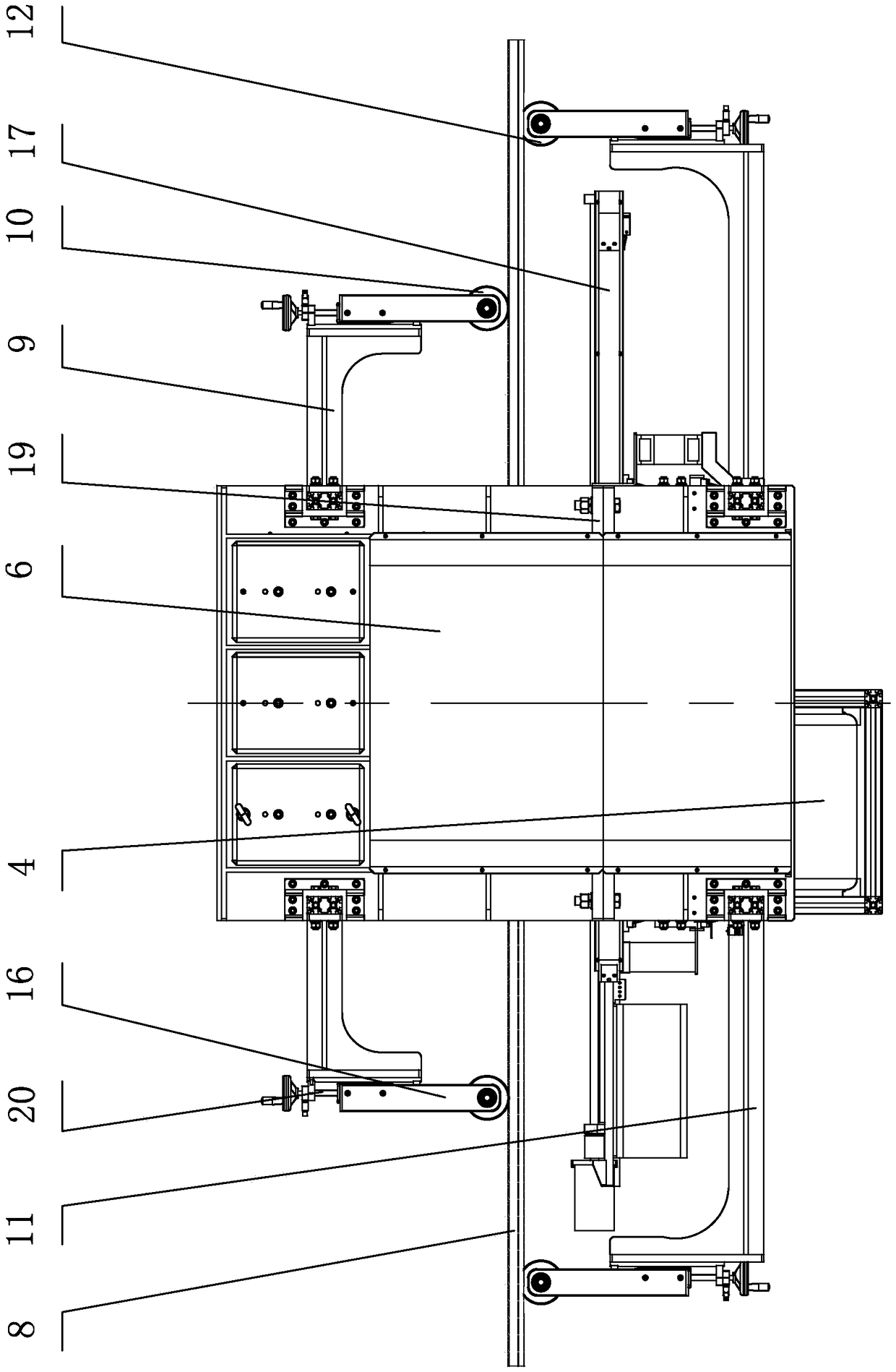

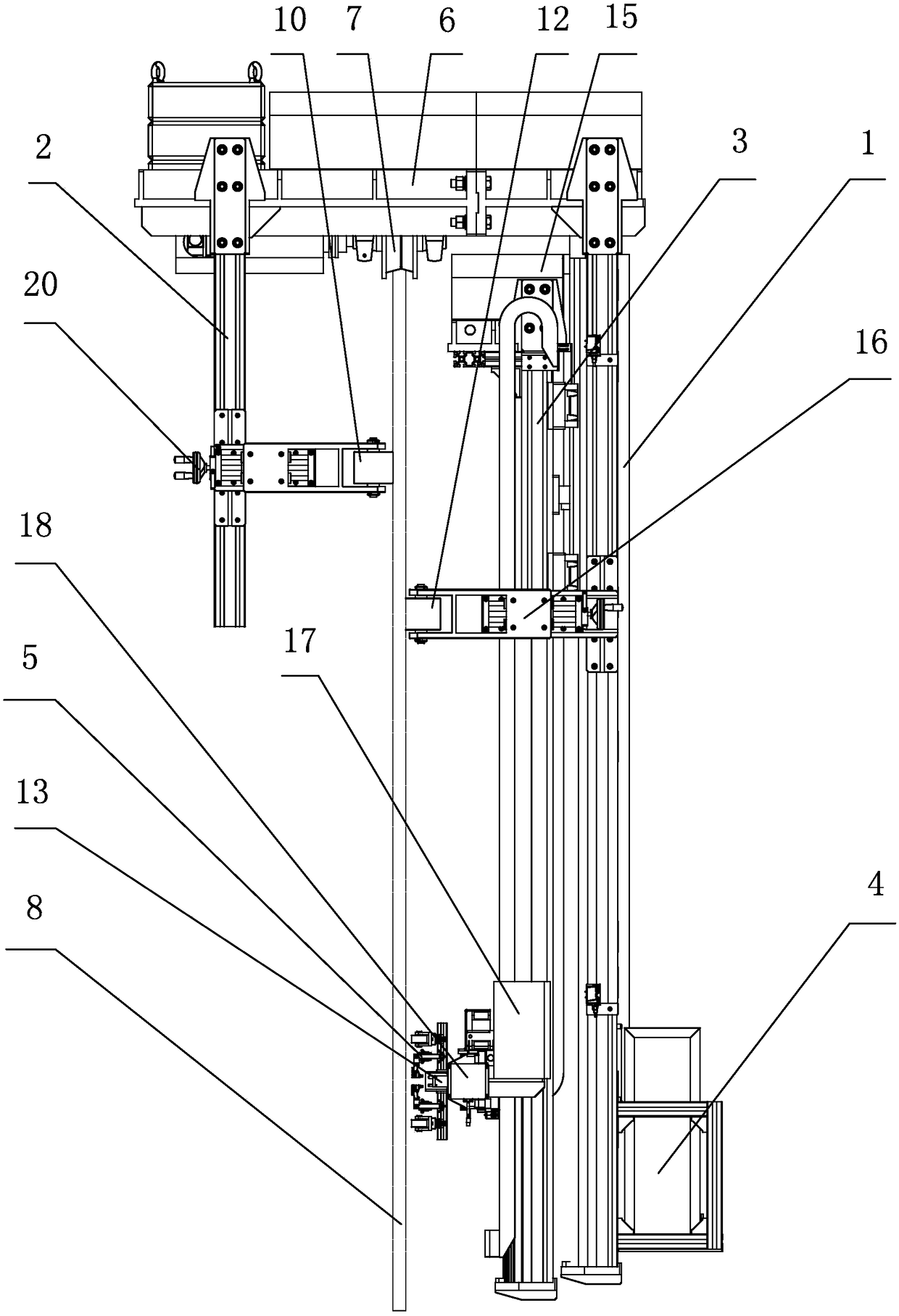

[0029] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0030] The ultrasonic phased array automatic detection device for steel large-scale vertical storage tanks of the present invention has a structure comprising a circular storage tank wall plate 8 ( Comprising the walking frame 6 that travels on the top of the longitudinal and transverse butt welds), the left and right traveling wheels 7 are installed in the center of the bottom of the traveling frame 6, and the left and right traveling wheels 7 are rolled and installed on the The top of the storage tank wall plate 8, the groove coincides with the groove on the top of the storage tank wall plate 8, and the left and right parts of the top of the walking frame 6 are respectively provided with left and right lifting lugs 19, such as figure 1 , figure 2 , image 3 , Figure 4 shown.

[0031] The bottom of the outer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com