Pit type gas heater and radioactive plant system

A gas heater and pit-type technology, applied in the field of radioactive plant systems, can solve the problems of wasting time, affecting the normal operation of nuclear fuel reprocessing plants, and dangerous, and achieve the effects of convenient maintenance, ensuring safety, and avoiding condensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

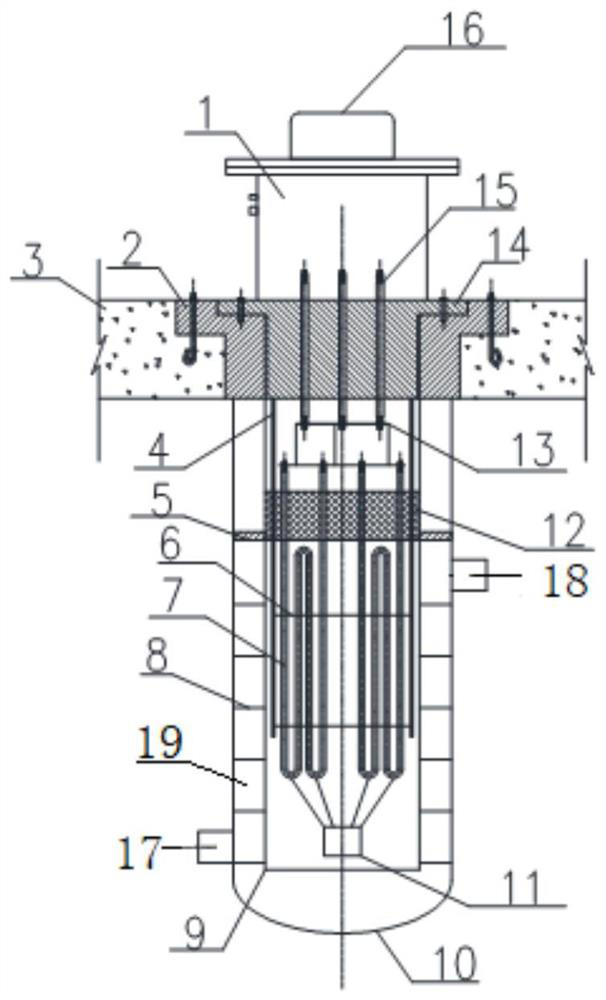

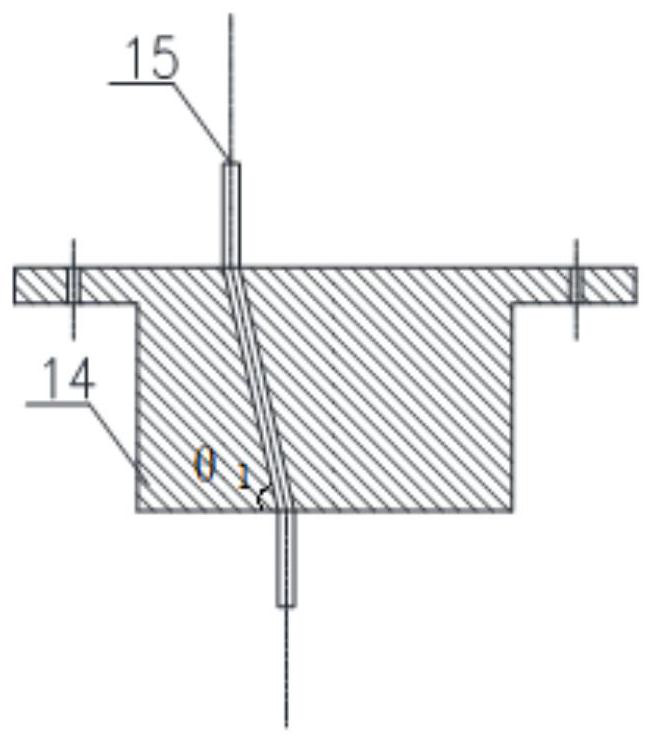

[0029] Such as figure 1 As shown, this embodiment discloses a pit-type gas heater, which includes a shell, a heating assembly, and a shielding assembly, wherein: the shielding assembly includes an inlay 2 and a penetration 14, and the inlay 2 is embedded in the roof of a radioactive place 3, the inlay 2 is provided with a first through hole, and the through part 14 is sealed in the first through hole in the form of a plug; the top of the housing is open, and the housing and the inlay 2 are connected by welding, etc., the shell The body is in the inside of the radioactive place; the heating assembly includes an electric heating tube 7 and a power lead-out rod 15, and the electric heating tube 7 is arranged inside the shell for heating the radioactive gas entering the shell from the radioactive place; the power lead-out rod 15 One end of it is electrically connected with the electric heating tube 7, and the other end passes through the through piece 14 and enters the outside of ...

Embodiment 2

[0052] This embodiment discloses a radioactive plant system, which includes an isolation room, and also includes the pit-type gas heater described in Embodiment 1, wherein the shielding assembly in the pit-type gas electric heater is embedded in the top plate of the isolation room 3, the housing is inside the isolation chamber, and the openings on the housing (i.e. the air inlet 18 and the air outlet 19) communicate with the isolation chamber. Specifically, the radioactive gas in the heat insulation chamber enters the flow channel through the air inlet 18, and is heated by the electric heating tube 7 when flowing through the flow channel 17. After heating, the radioactive gas is discharged from the gas outlet 19, and the heated The temperature of the radioactive gas can reach above 120°C.

[0053] The radioactive plant system of this embodiment, because the pit-type gas heater described in Embodiment 1 is used, can heat the radioactive gas in the isolation room, thereby avoidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com