An Axial Moving Multi-mode Hydraulic Variable Valve Drive System

A drive system, axial movement technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., to achieve good application prospects, high reliability, and compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

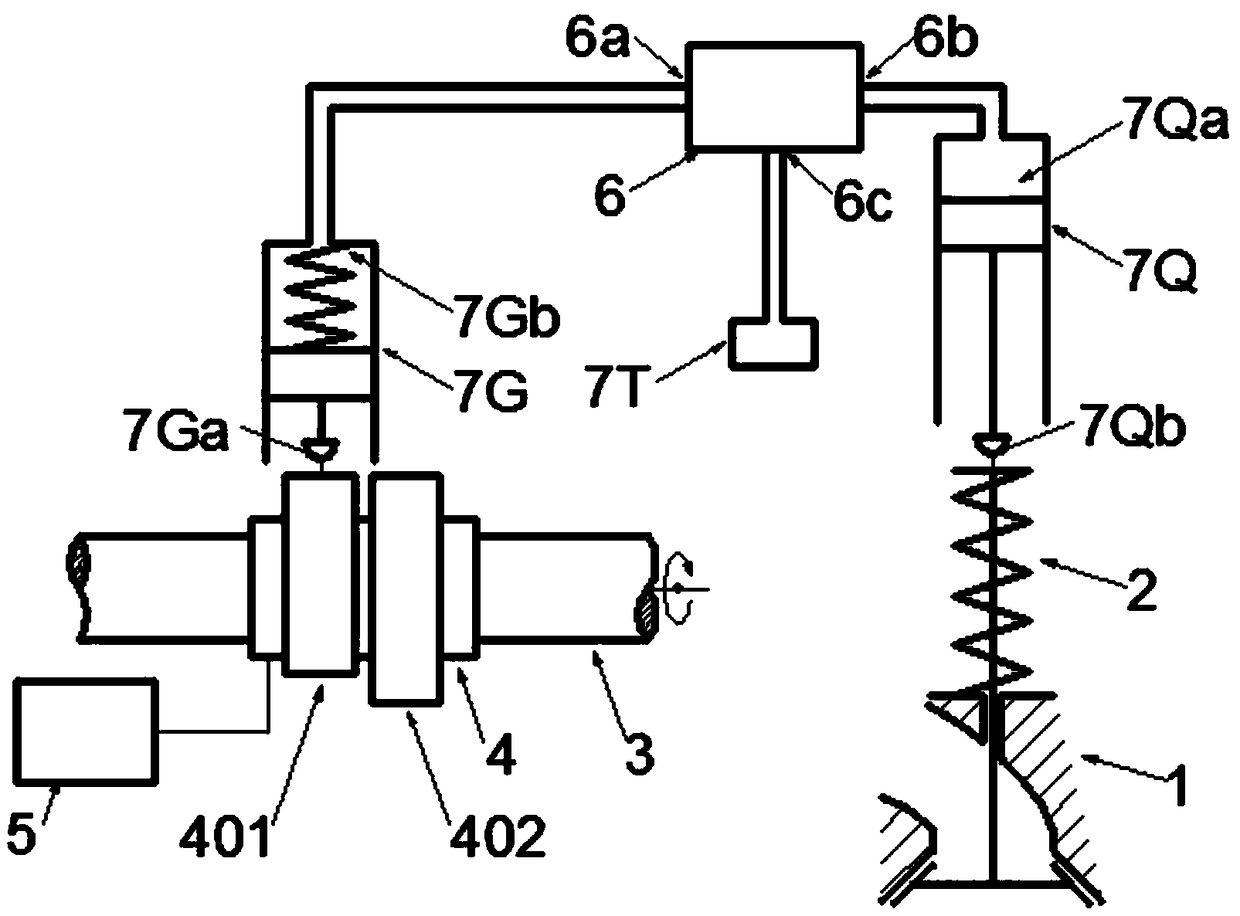

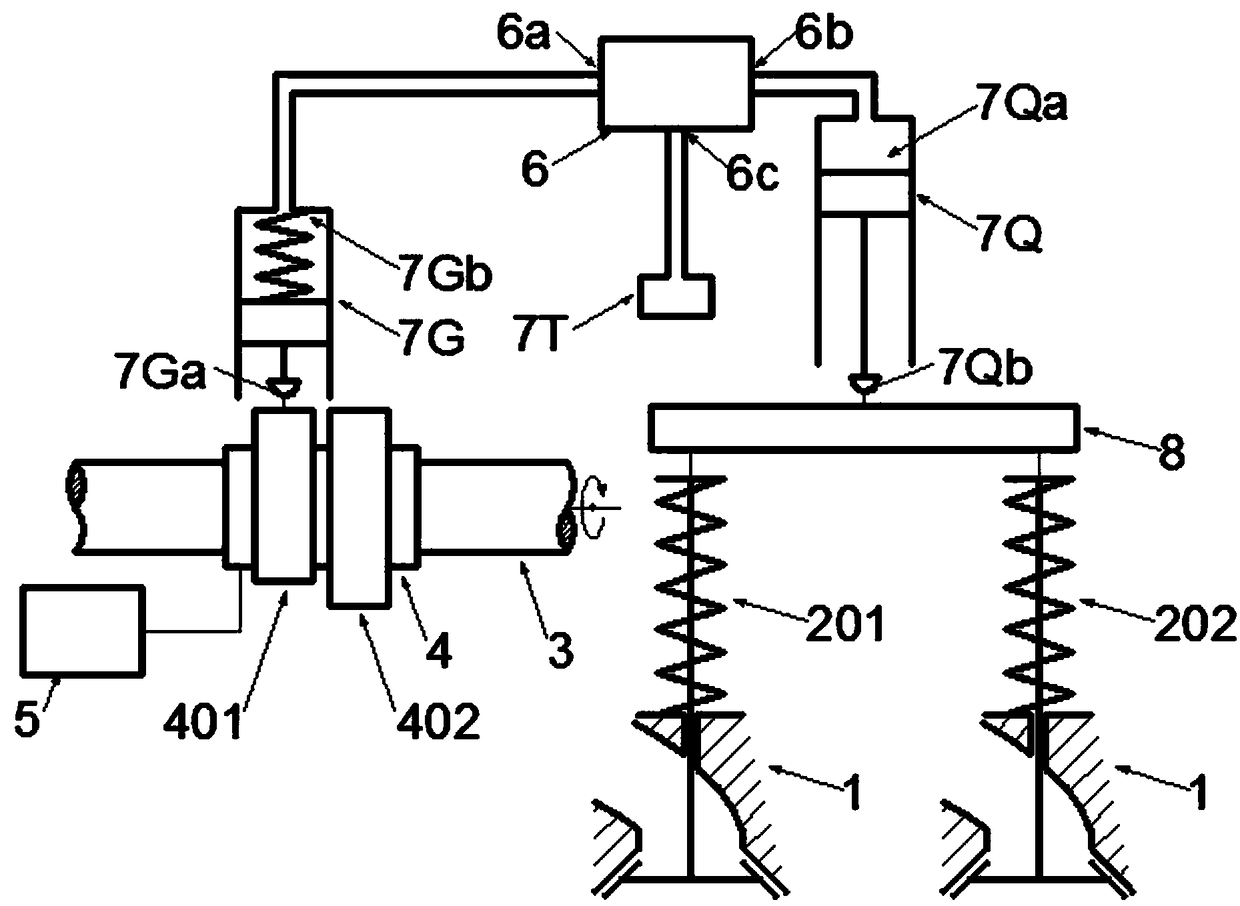

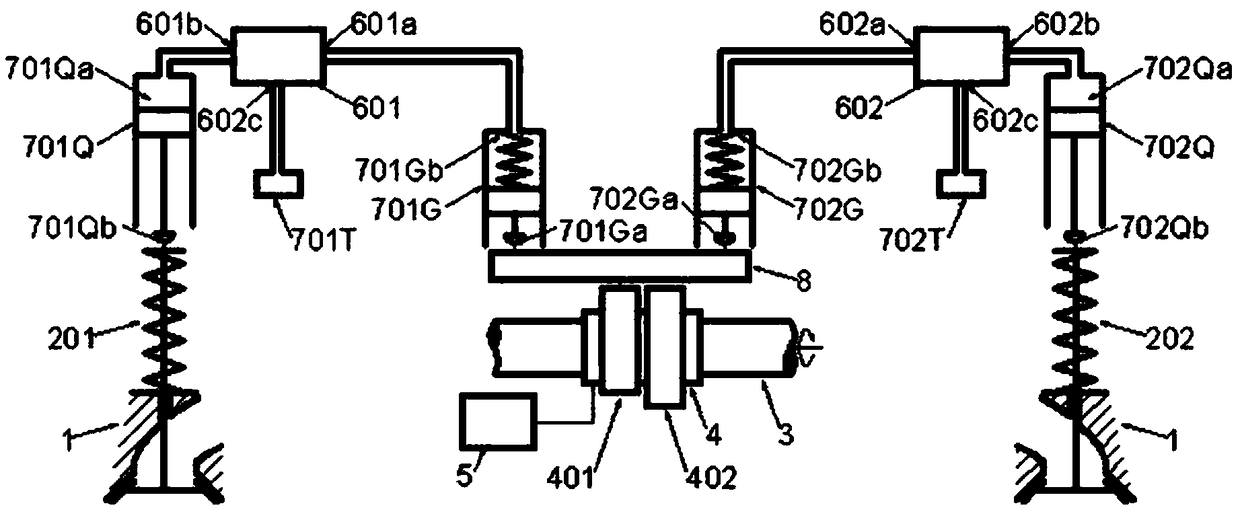

[0047] The invention relates to an axially movable multi-mode hydraulic variable valve drive system. It includes valve driving mechanism 2, camshaft 3, camshaft sleeve 4, axial movement mechanism 5, valve control mechanism 6, plunger type oil supply device 7G, piston type driver 7Q and oil reservoir 7T. figure 1 It is a schematic diagram of an axially moving multi-mode hydraulic variable valve drive system with a single camshaft bushing and a single set of cams, a double cam drive, a single valve operation and a single adjustment. A first cam 401 and a second cam 402 are arranged on the camshaft sleeve 4 . The first cam 401 adopts a single-lobed cam blade or a double-lobed cam blade, the second cam 402 adopts a single-lobed cam blade or a double-lobed cam blade, and the double-lobed cam blades adopt camshafts with the same profile and a phase difference of 180° Two protrusions at the corners. The plunger type oiler 7G has a plunger input port 7Ga and an oil supply chamber 7G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com