Nut plate mounting device and punching process

An installation device and nut plate technology, applied in the field of metal stamping, can solve the problems of narrow space, loose joints, easy deformation, etc., and achieve the effects of improving safety factor, reliable connection, and strengthening structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

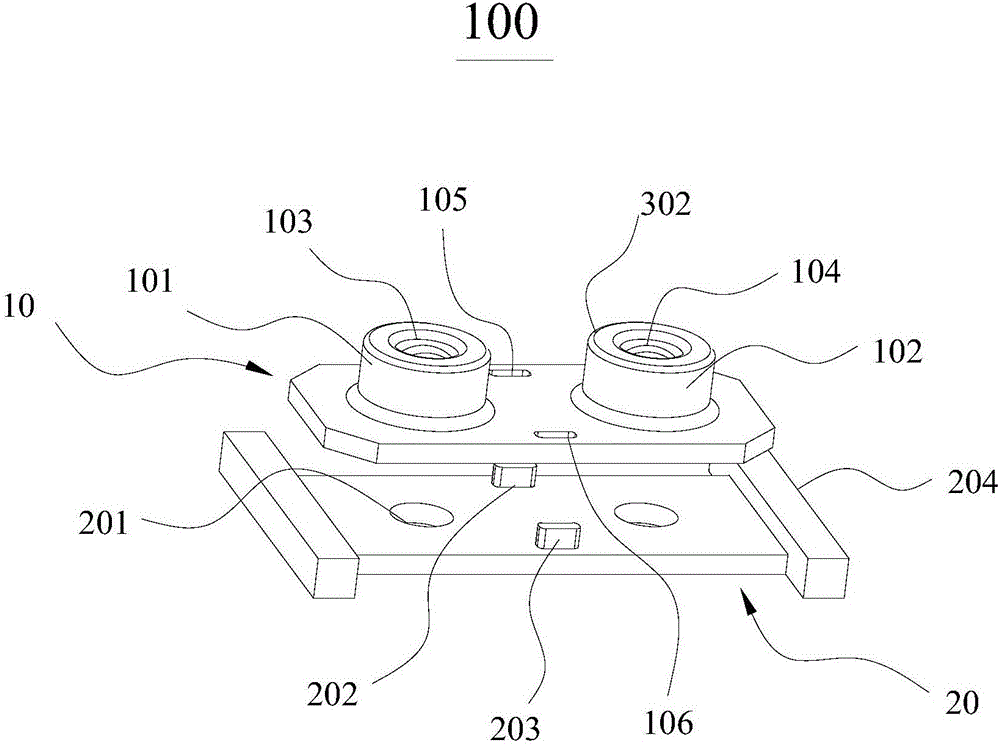

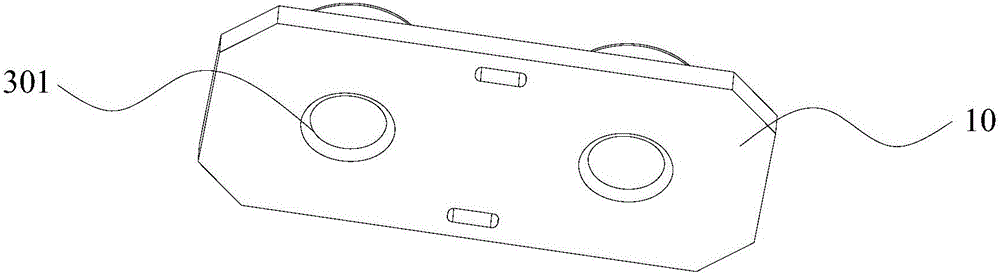

[0049] Please refer to figure 1 , figure 1 A nut plate installation device 100 provided for this embodiment includes a nut plate 10 and a mounting plate 20 .

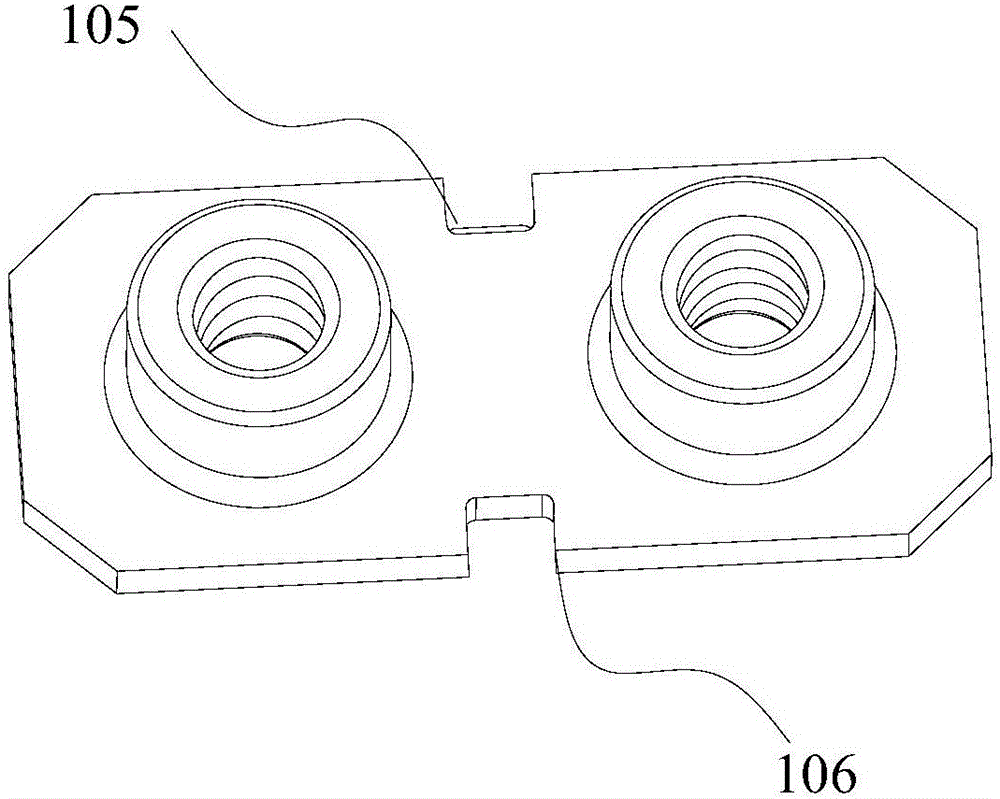

[0050] The nut plate 10 is provided with a first limiting boss 101 and a second limiting boss 102 which are arranged symmetrically; The second chamfer 302, and the connection between the first limiting boss 101 and the second limiting boss 102 and the nut plate 10 is a circular arc transition.

[0051] The first positioning boss 101 defines a first positioning hole 103 penetrating through the nut plate 10 , and the second limiting protrusion 102 defines a second positioning hole 104 penetrating through the nut plate 10 . The height of the first limiting boss 101 is equal to that of the second limiting boss 102; the diameter of the first positioning hole 103 is equal to that of the second positioning hole 104, and both are provided with internal threads; please refer to figure 2, the connection between the first posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com