Shaft core and worm wheel integrated double-axis synchronous damping rotary shaft

A damping shaft, integrated technology, applied in the direction of pivot connection, etc., can solve the problems of large occupied space and poor strength, and achieve the effect of small occupied space, good strength, perfect and smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

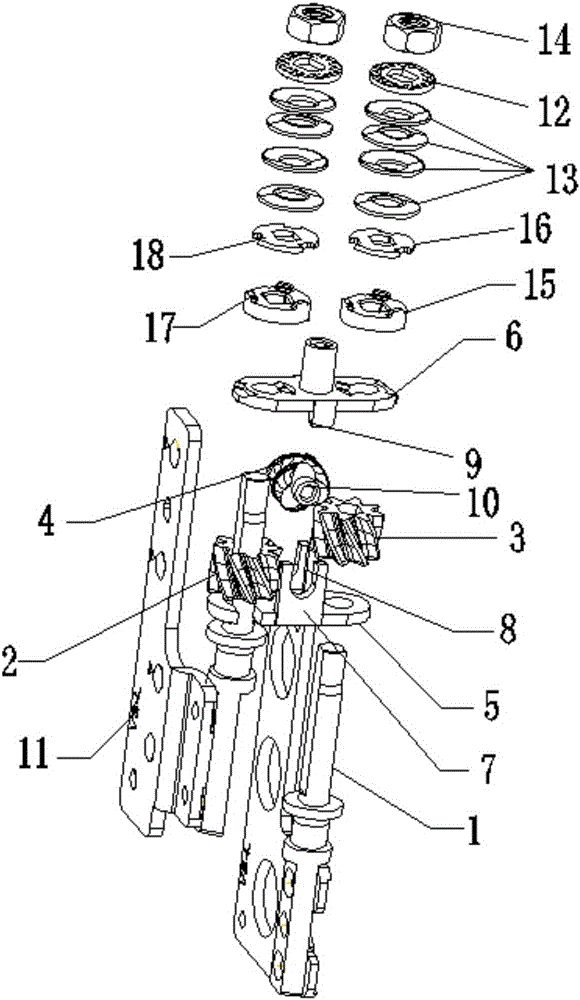

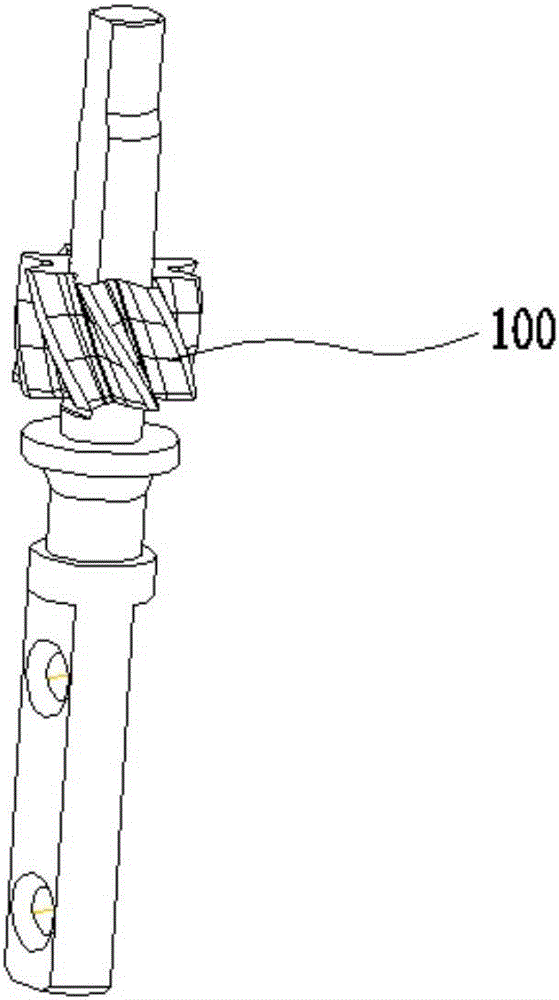

[0026] Such as figure 1 and figure 2 As shown, a shaft center and worm gear integrated dual-axis synchronous damping shaft, including two shaft cores 1, two worm gears 2, 3, a worm 4 and at least two limit connecting plates 5, 6, one of the worm gears It is sleeved on one of the shaft cores, and the other worm gear is sleeved on the other shaft core; the two limit connecting plates are both sleeved on the two shaft cores, and are located on the two shaft cores. On both sides of the two worm wheels, the two shaft cores are radially separated by a set distance, and can freely rotate in the circumferential direction relative to the two limit connecting plates; the worm is arranged on the two lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com