Non-water-cutoff construction method for water-break mounting and maintaining of water supply pipeline

A technology for water supply pipelines and construction methods, applied in the directions of pipes, pipe components, branch pipelines, etc., can solve problems such as unstoppable water and difficult construction, and achieve the effects of solving unstoppable water, simple methods, and easy-to-operate methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

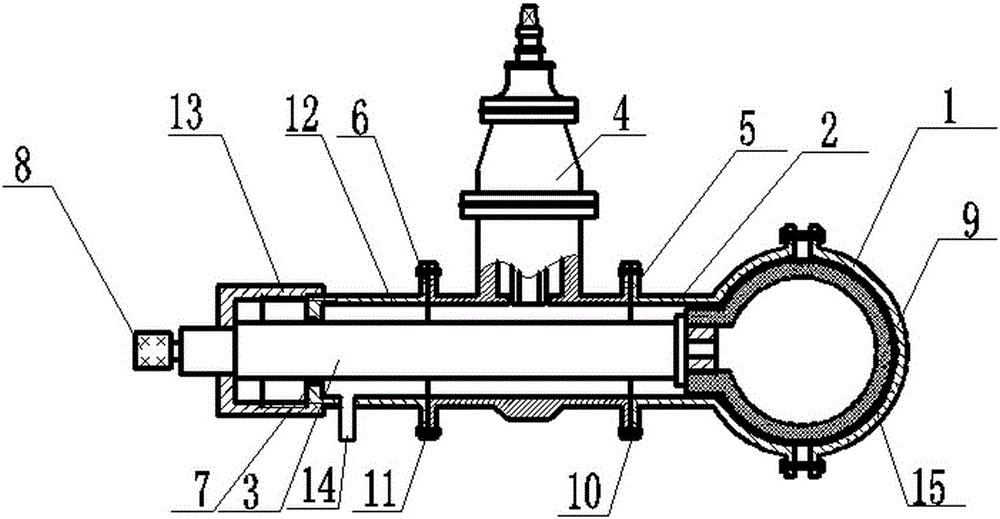

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, a non-stop water construction method for installation and maintenance of water supply pipelines without water supply, the half tee 1 is set on the outer periphery of the water pipe 15, and the branch pipe 2 of the half tee 1 is connected to one end of the gate valve 4, and the gate valve The other end of 4 links to each other with the non-stop water opening drill body 12, drills the opening on the water pipe pipeline 15 to be constructed with the non-stop water opening drill, after the water pipe pipeline 15 openings, extract the drill pipe of the non-stop water opening drilling, and put down the gate valve 4. To prevent running water, then, replace the drill pipe of the non-stop water opening drill with a rubber plug hollow jacking rod 3, and install an inflatable rubber plug 9 on the rubber pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com