Large-object three-dimensional measurement LED label calibration method based on tracker

A technology of three-dimensional measurement and calibration method, applied in the field of three-dimensional measurement, can solve the problems of large matching errors, low calibration accuracy and robustness, and inability to accurately find spatial calibration objects, so as to reduce the possibility of wrong matching and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

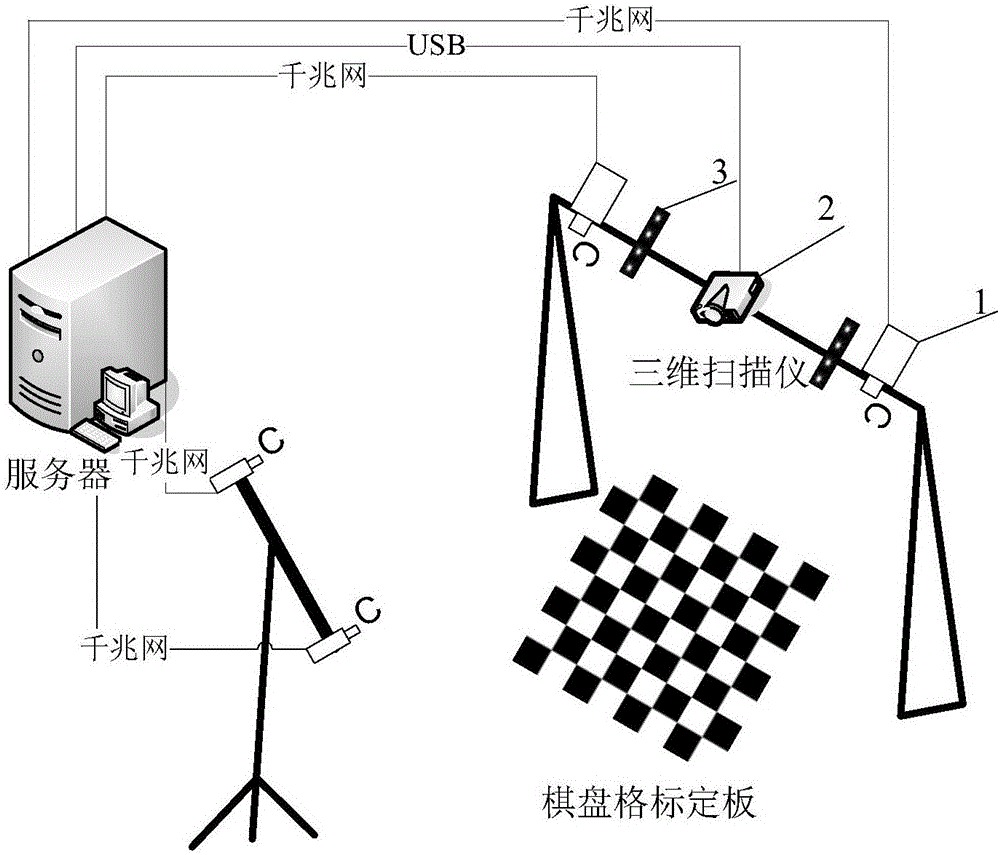

[0041] figure 1 It is a simple schematic diagram of the system structure applicable to the present invention. like figure 1 As shown, the applicable system of the present invention includes a three-dimensional scanner (containing two industrial cameras and a projector), a stereo tracker (containing two industrial cameras), a checkerboard calibration board, and a high performance GPU server.

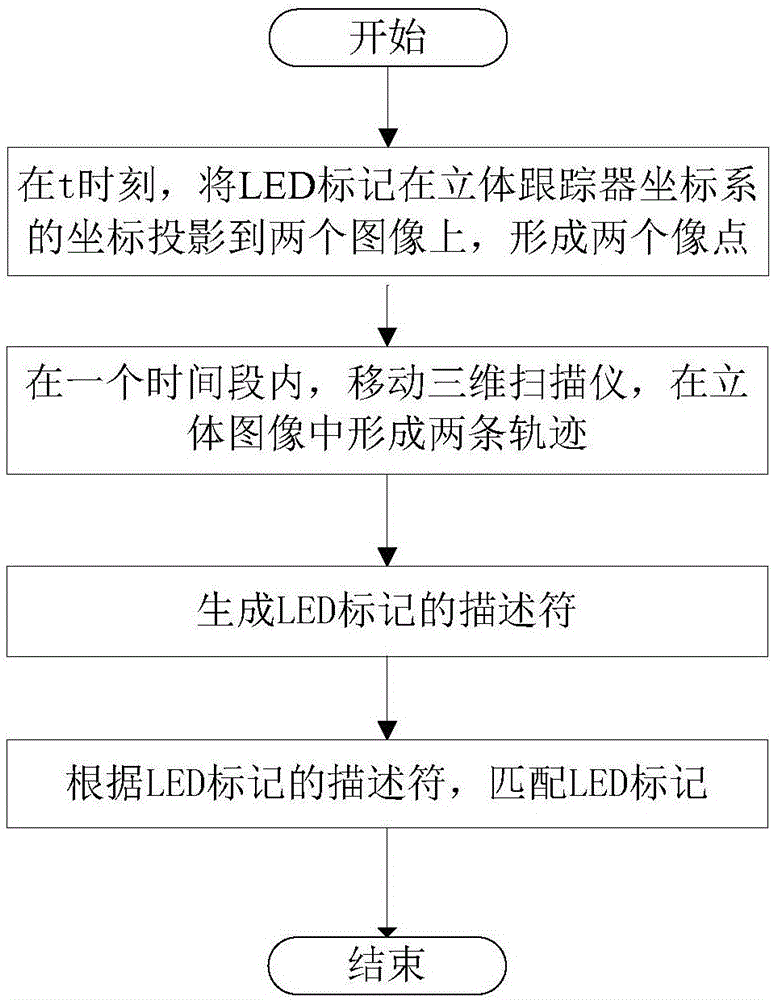

[0042] The method described in the method of the present invention comprises: first installing a plurality of LED marks on the three-dimensional scanner, and then performing the following steps:

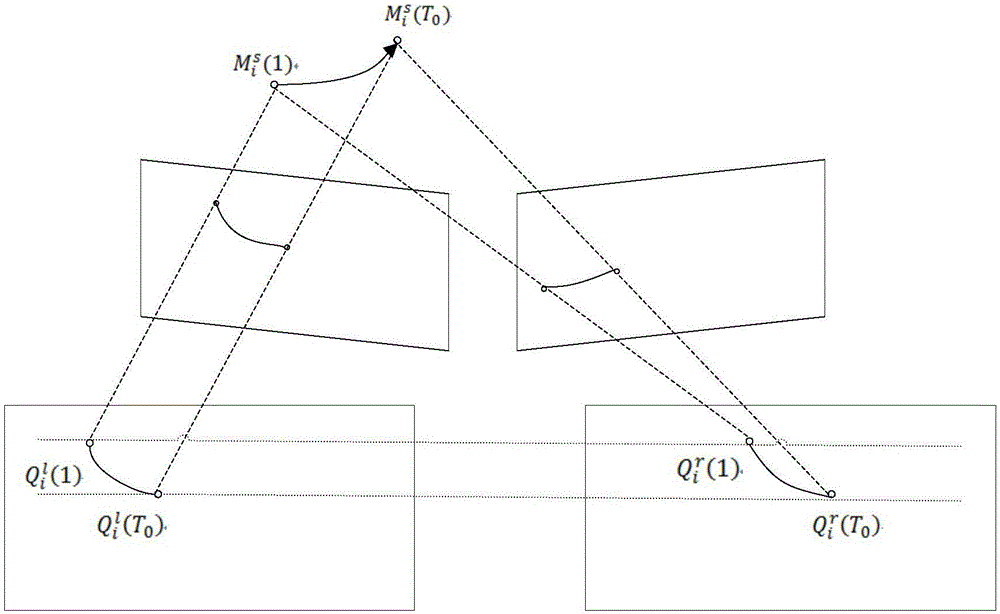

[0043] (1) Match the LED mark with the LED mark matching method based on the trajectory: the motion track of the LED mark in the field of view of the stereo tracker observed by the stereo tracker; observe the two cameras of the stereo tracker The trajectory of the LED marker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com