Effect target structure for measuring peak value of impact wave pressure of movable target, and testing method

A technology of shock wave and target structure, which is applied in the direction of measuring blasting force, etc., and can solve the problems of large diameter effect target weight, error, and low resonance frequency of large diameter effect target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

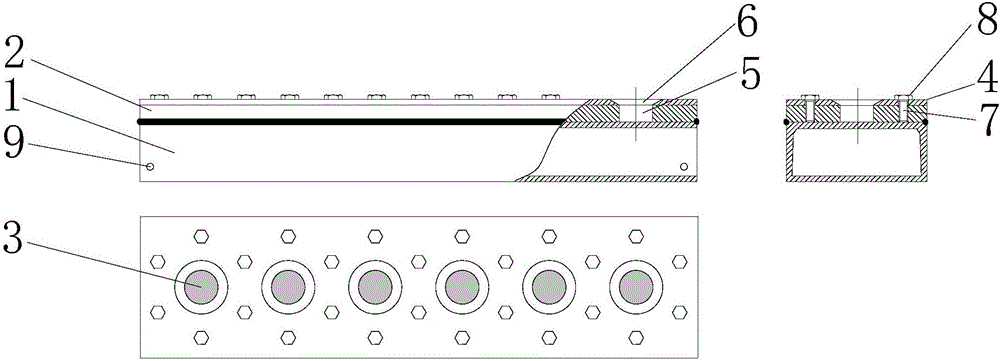

Method used

Image

Examples

Embodiment 1

[0061] In the static explosion test of 5kg spherical TNT explosive, the explosive is attached to the ground surface, and the shock wave pressure of the explosion shock wave at the effect target position is measured through the above effect target structure. Including the following steps:

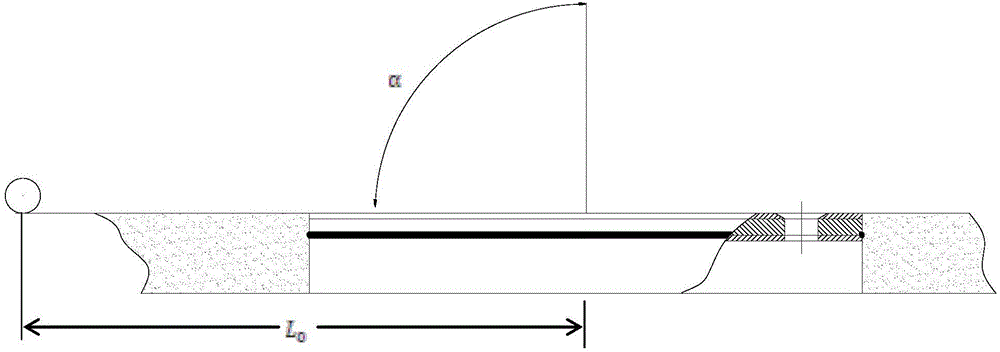

[0062] Step 1: Effect target structure installation

[0063] Such as figure 2 The center of the effect target shown is 3.46m away from the center of the explosive. Dig a pit on the surface where the effect target is located, place the effect target in the pit, and adjust the position so that the upper surface is flush with the ground surface;

[0064] Step 2: Read effector target data

[0065] The shock wave acts in front of the effect target, and the 6 depth values of the pressure response diaphragm from the cover plate are measured with a depth gauge and recorded as H i (i=1, 2, 3, 4, 5, 6); after the shock wave acts on the effect target, use the depth gauge to measure the six depth ...

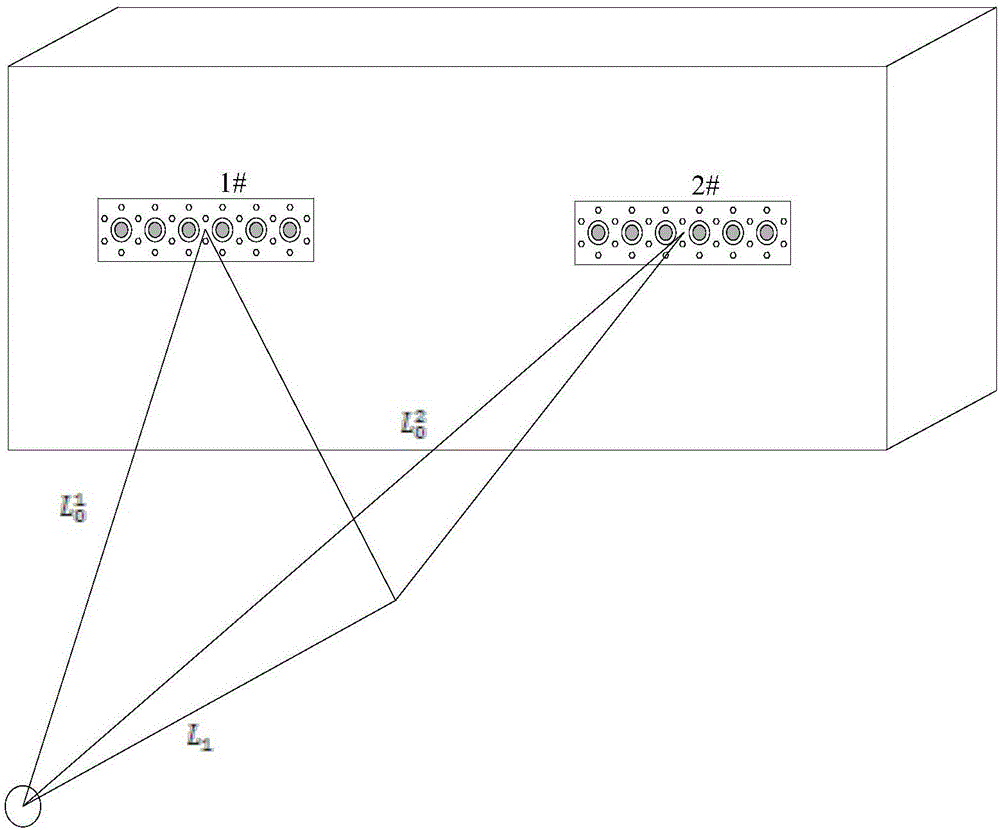

Embodiment 2

[0082] In order to obtain the damage effect of a certain explosive charge on the container target, the shock wave load on the windward side of the container is measured through the above effect target as follows: image 3 shown. The explosive is a 100Kg cylindrical TNT charge, and the explosive height is 2m. The center of the container is 15m away from the center of the explosive. The windward side of the container is perpendicular to the line connecting the explosive and the center of the container. It mainly includes the following steps:

[0083] Step 1: Effect target structure installation

[0084] Such as image 3 As shown, the effect target is connected to the container through a strong magnet, the upper surface is parallel to the windward side of the container, and the effect target is placed laterally. The installation height of the two effect targets is 1.2m, the vertical distance between the center of the 1# effect target and the container head is 1m, and the dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com