Rail transverse excitation equipment

A rail and vibration excitation technology, applied in the field of railway engineering, can solve problems such as undiscovered loading units, achieve important engineering application value, solve the effect of excessive size and accurate simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the embodiments shown in the accompanying drawings.

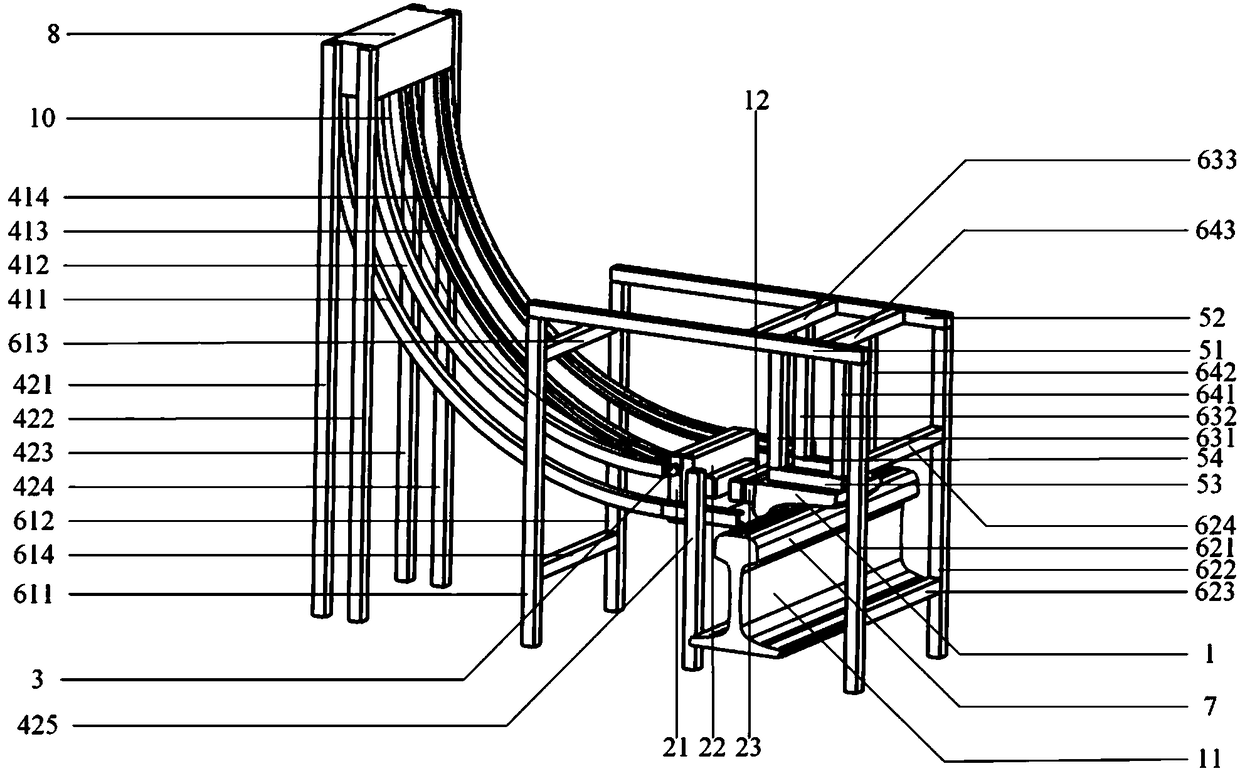

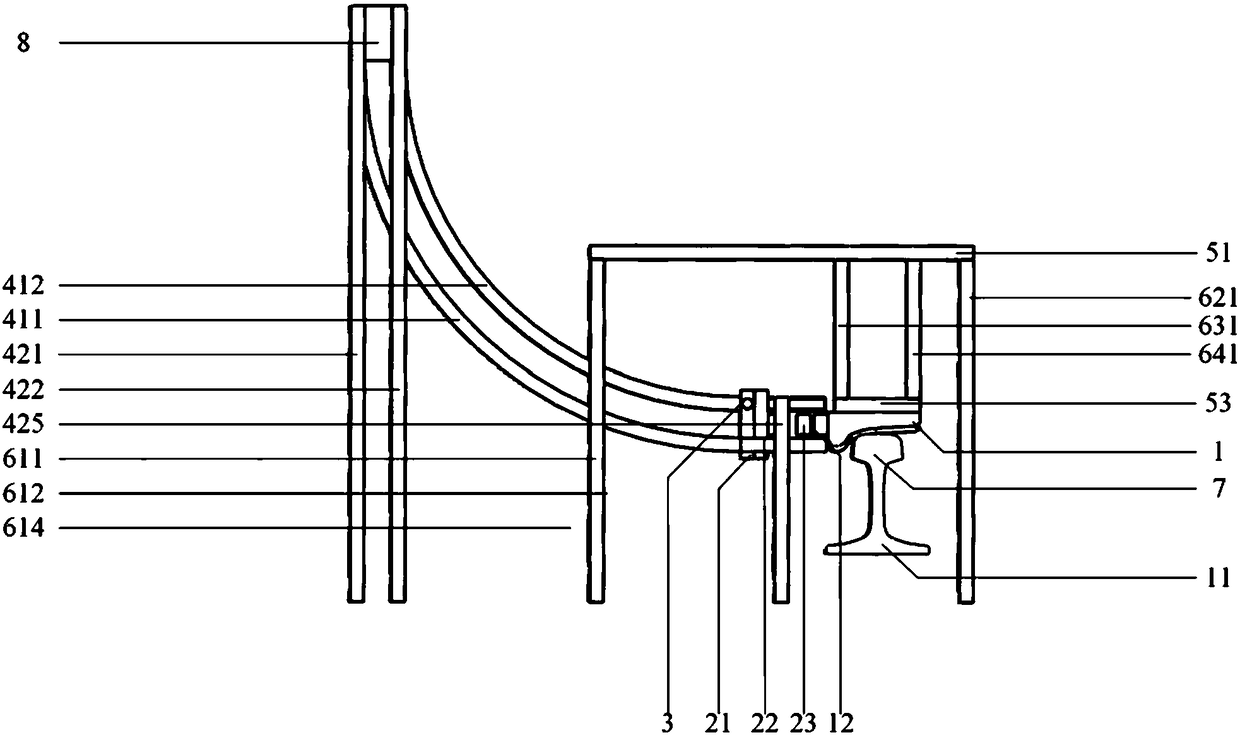

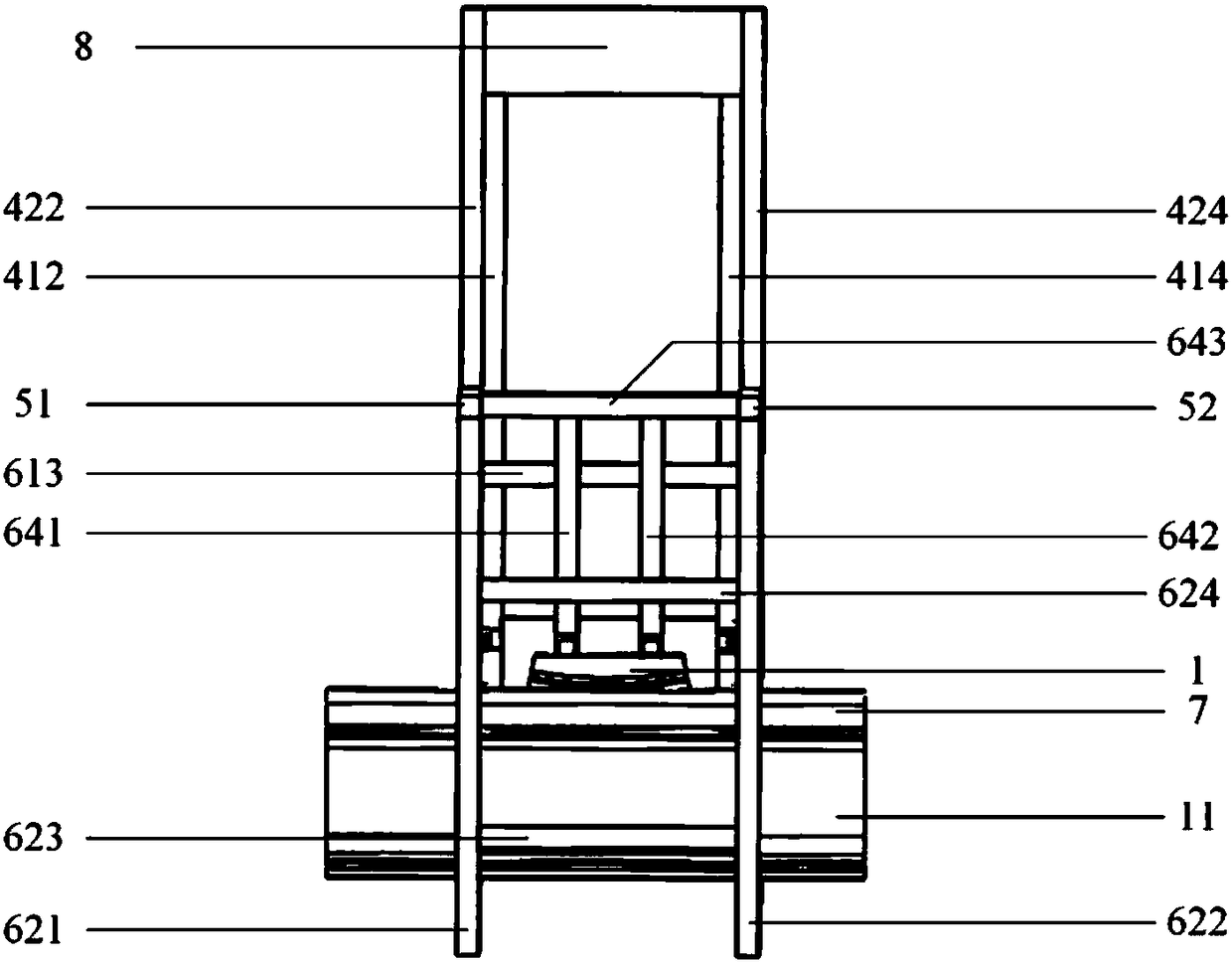

[0026] combine Figure 1 to Figure 3 As shown, the present invention first provides a rail transverse vibration excitation device, which includes a control system, a reaction force system and a loading unit, and the loading unit is respectively connected with the control system and the reaction force system.

[0027] The control system is a computer control system, which is connected with the loading unit through lines for control.

[0028] The reaction force system includes: a frame structure; a slideway formed by a first loading crank rod 411, a second loading crank rod 412, a third loading crank rod 413, and a fourth loading crank rod 414; a first loading vertical rod 421, the potential energy conversion frame formed by the second loading vertical rod 422, the third loading vertical rod 423, and the fourth loading vertical rod 424; the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com