Train impact model testing device

A test device and impact model technology, applied in measurement devices, impact testing, railway vehicle testing, etc., can solve the problems of large computational workload, complex numerical modeling, low reliability, etc., to achieve accurate simulation data, reduce casualties and loss, avoidance of serious damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

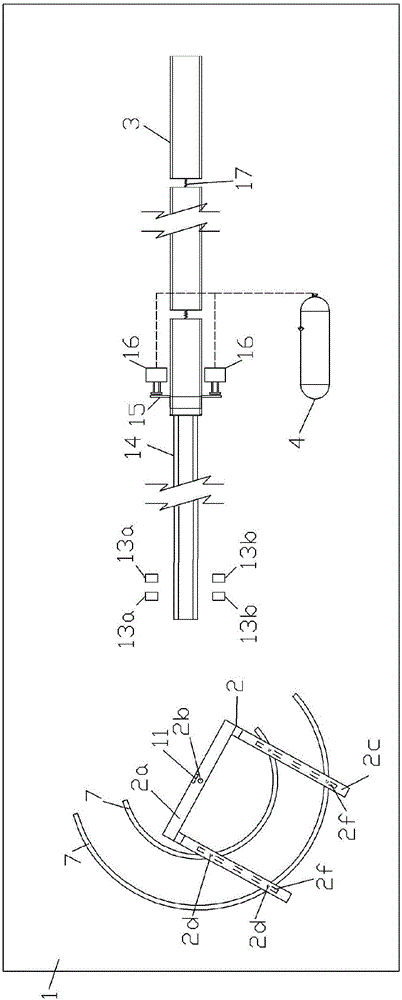

[0024] figure 1 Shown, a kind of specific embodiment of the present invention is, a kind of train impact model test device, it is characterized in that:

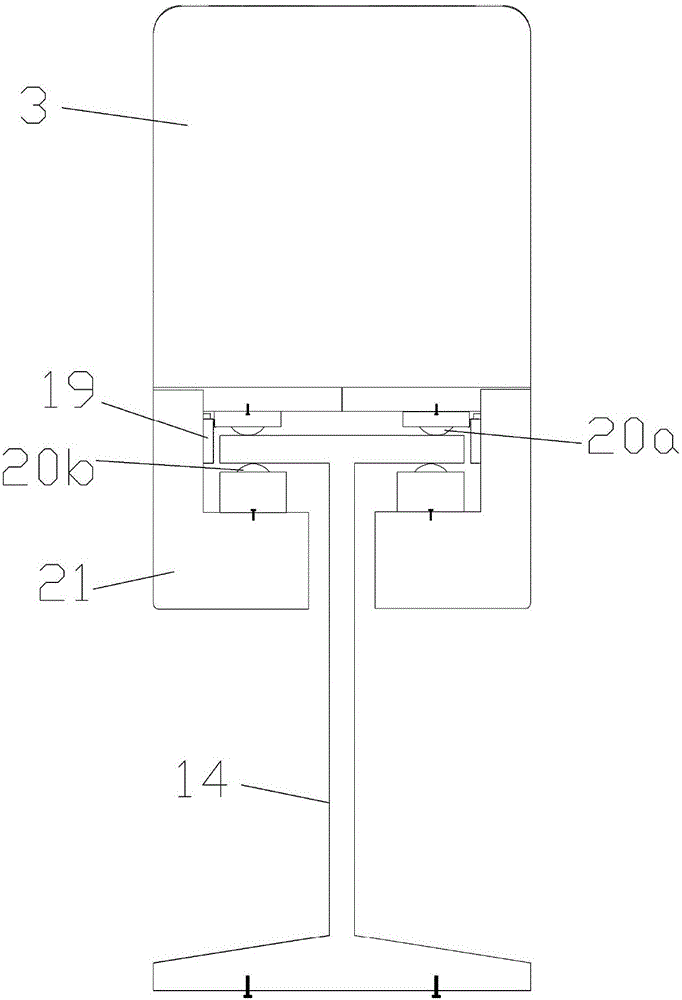

[0025] The middle part of table top 1 places the I-shaped steel 14 of simulated track, and the train marshalling model 3 is installed on the I-shaped steel 14; The two sides of the front part of the train marshalling model 3 are provided with wing plates 15, fixed on the table top 1 just behind the wing plate 15 There is an impact cylinder 16; the impact cylinder 16 is connected with the air compressor 4;

[0026] The platform 1 in front of the train formation model 3 is fixed with an angle-adjustable rigid baffle 2 simulating the side wall of the tunnel, and a force sensor 11 is installed in the middle of the rigid baffle 2;

[0027] Two laser emitters 13a are installed on the table 1 on one side of the front part of the I-shaped steel 14, and two laser sensors 13b are installed on the table 1 on the other side of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com