Automatic carrying type steel plate test robot

A robot and plate technology, applied in the direction of testing material strength by applying stable bending force, instruments, and testing material strength by applying stable tension/compression, can solve the problem of not being able to solve the problem of steel plate testing and failure to reach the test The mechanical properties of steel and the lack of high efficiency have achieved the effect of simple and easy-to-learn test operation, saving manpower and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

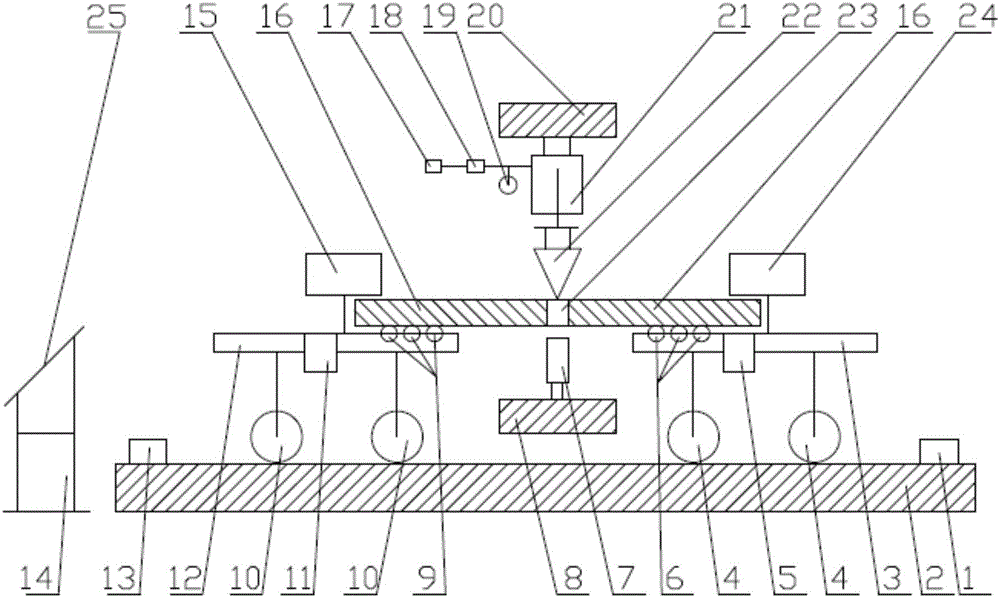

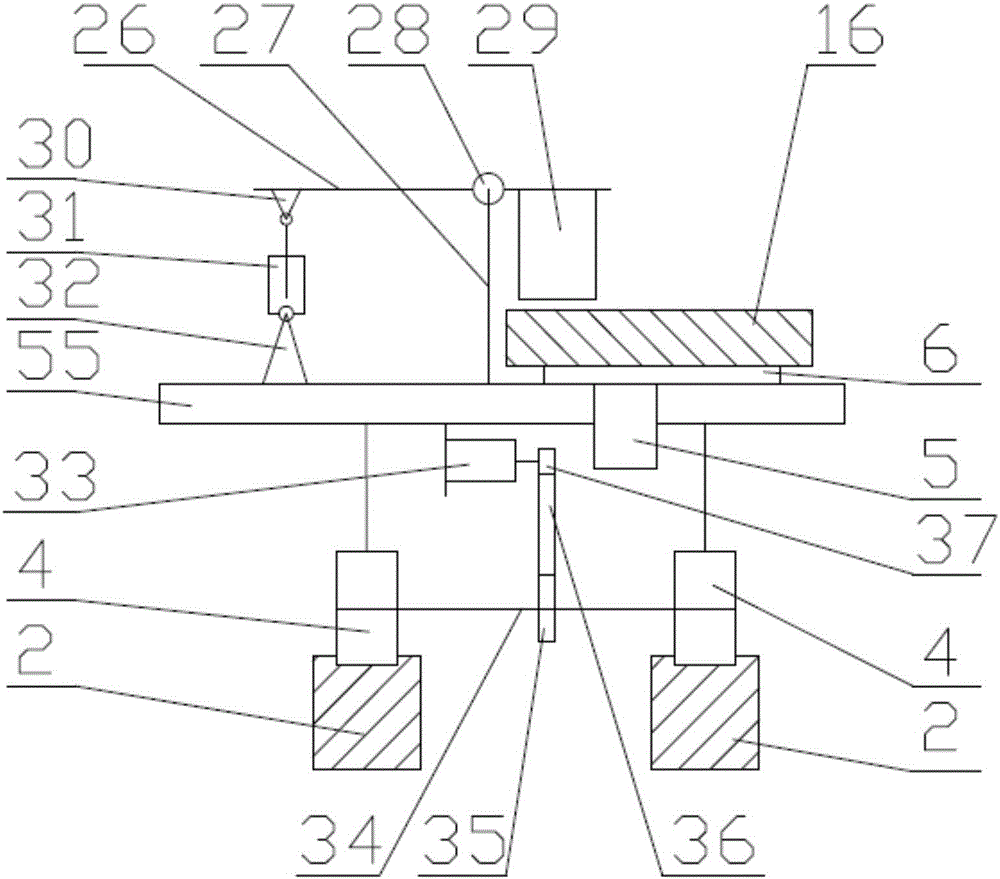

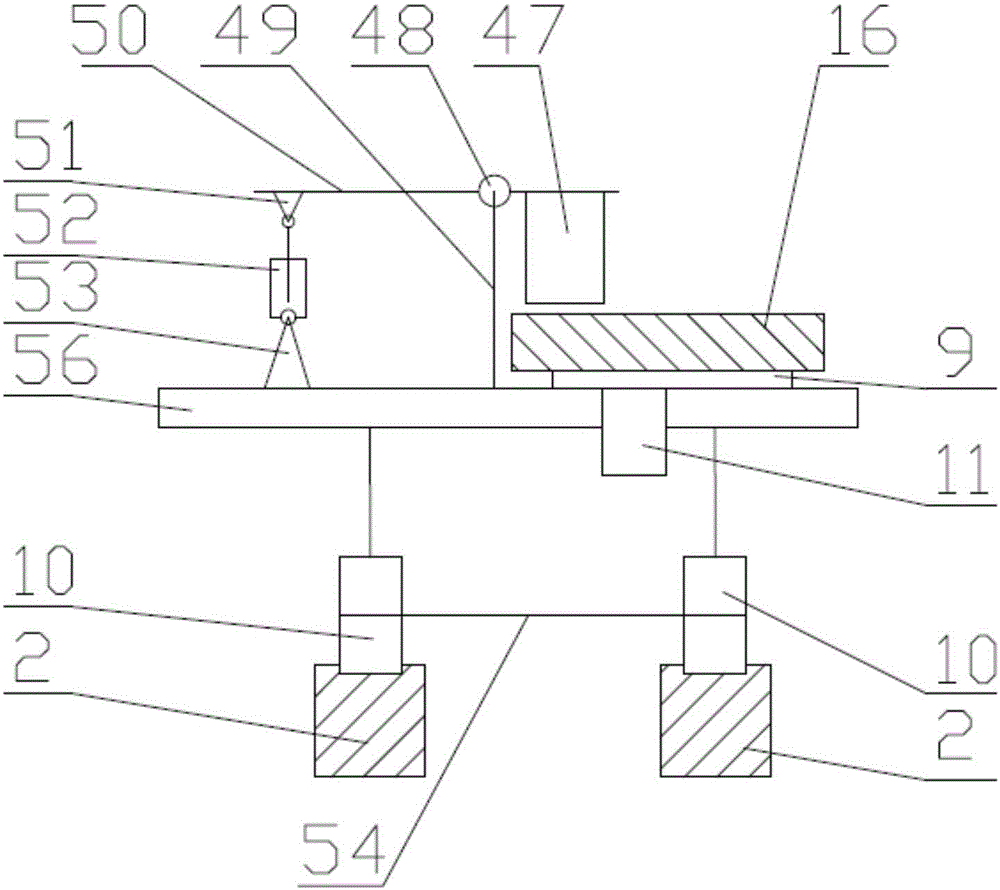

[0027] As per above figure 1 , figure 2 , image 3 , Figure 4 As shown, an automatic handling steel plate testing robot is prepared, including a guide rail 2, a guide platform 3, a follower platform 12, a testing device, and a control system; the aforementioned guide platform 3 and follower platform 12 are arranged on the guide rail 2 and can be The guide rail 2 moves left and right, the guide platform 3 is on the right, the follower platform 12 is on the left, and the test device is located on the upper side and between the guide platform 3 and the follower platform 12. The test device is used to position the steel plate 16 And apply pressure to test the bending strength of the steel plate 16; the guide platform 3 includes: guide wheel 4, roller A 6, proximity switch A 5, clamping mechanism A24, lever A 26, support rod A 27, hinge A 28, Compression block A 29, hinge support A 30, cylinder A 31, hinge support B 32, motor 33, axle A 34, timing belt wheel A 37, timing belt 36, t...

Embodiment 2

[0030] As per above Figure 5 As shown, the end of the contact 22 is designed to have a flat shape, and the flat shape can be used to test the deformation of the steel plate 16 under equal pressure. The others are the same as in Embodiment 1.

[0031] Let's take a test job as an example.

[0032] In the first step, the steel plate 16 is installed

[0033] The robot starts and completes the self-inspection. The guiding platform 3 and the following platform 12 are both on the left side of the guide rail 2. One end of the steel plate 16 is manually placed on the roller A 6 on the guiding platform working surface 55, and the steel is pushed forward Plate 16, place the steel plate 16 above the proximity switch A 5, and place the remaining part of the steel plate 16 on the roller B 9 on the working surface 56 of the follower platform to complete the installation of the steel plate 16.

[0034] The second step, automatic handling

[0035] The proximity switch A 5 detects that the steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com