Moving body measurement and initialization apparatus

A moving body, initialization technology, applied in the direction of photolithography process exposure devices, microlithography exposure equipment, etc., can solve the problems of high installation accuracy, reduced measurement accuracy, and the inability to initialize the balance quality module, to improve work efficiency, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

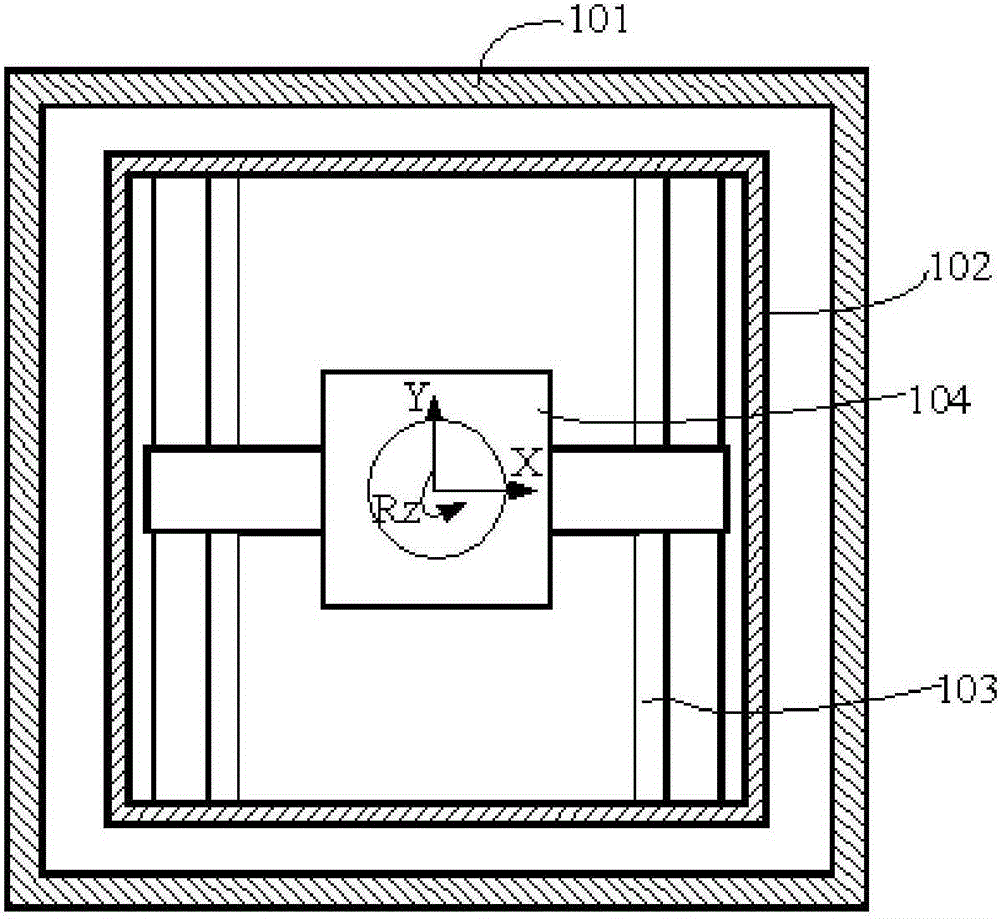

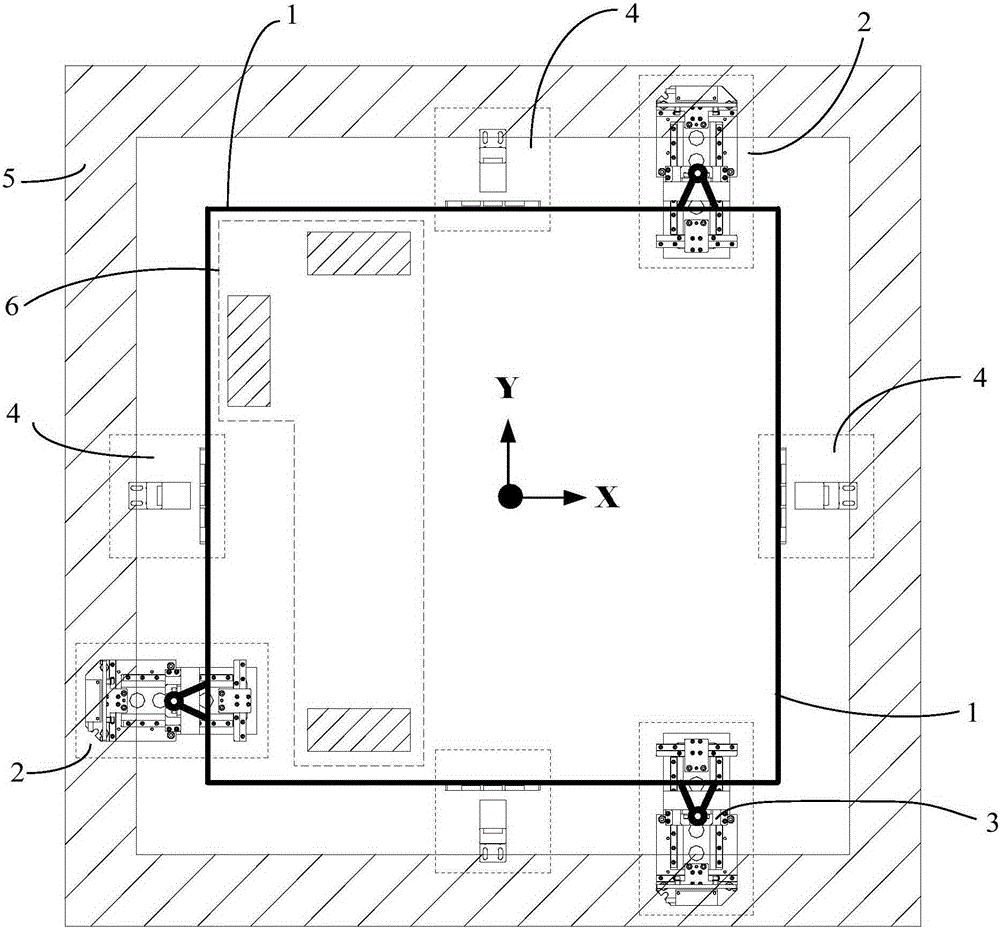

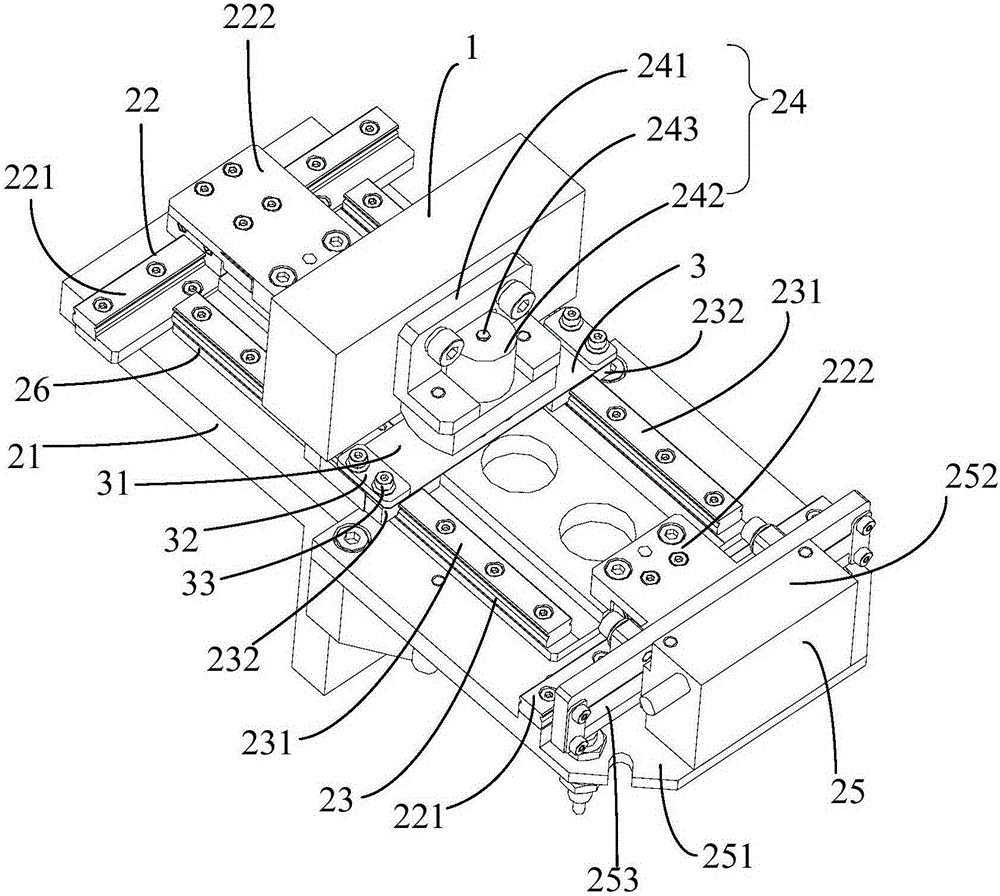

[0036] Such as figure 2As shown, the present invention provides a measurement and initialization device for a moving body, which is used to measure the displacement of the moving body 1 in the X, Y and Rz directions and initialize and reset the moving body 1. The moving body 1 is arranged on the installation frame 5 Above, the installation frame 5 is fixed, and the moving body 1 moves relative to the installation frame 5 along X, Y and Rz directions. There are also three compensating motors 6 connected to the moving body 1 on the installation frame 5 , two of which are distributed along the X direction, respectively controlling the movement of the moving body 1 along the X, Y and Rz directions. The device includes three groups of two-dimensional measuring mechanisms 2, decoupling mechanisms 3 arranged on each group of said two-dimensional measuring mechanisms 2, and four groups of initial reset mechanisms 4, wherein two groups of said two-dimensional measuring mechanisms 2 ar...

Embodiment 2

[0048] Such as Figure 9 As shown, the difference from Embodiment 1 is that the flexible decoupling piece 31 is provided with two pieces, the middle part of the flexible decoupling piece 31 is provided with a U-shaped opening, and the U-shaped openings of the two flexible decoupling pieces 31 are along the The X direction is oppositely arranged, and nuts 33 are arranged above the left and right ends of each flexible decoupling piece 31 , and the flexible decoupling piece 31 and the second slider 232 are provided with screw holes matching the nuts 33 (not shown in the figure), the flexible decoupling piece 31 and the second sliding block 232 are fixed by the nut 33 . Specifically, the material of the flexible decoupling piece 31 is 0Cr18Ni9 stainless steel. Due to the large ratio of length to thickness, when the moving body 1 deviates in the Rx, Ry, and Z directions due to component assembly errors, the flexible decoupling piece 31 will generate The deformation of Rx, Ry and Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com