General product assembly pressing attaching device

A product and pressing plate technology, applied in the field of general product assembly pressing device, can solve the problems of low work efficiency, uncontrollable pressing force and pressure holding time, etc., and achieve the effect of improving production efficiency, reducing labor cost and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

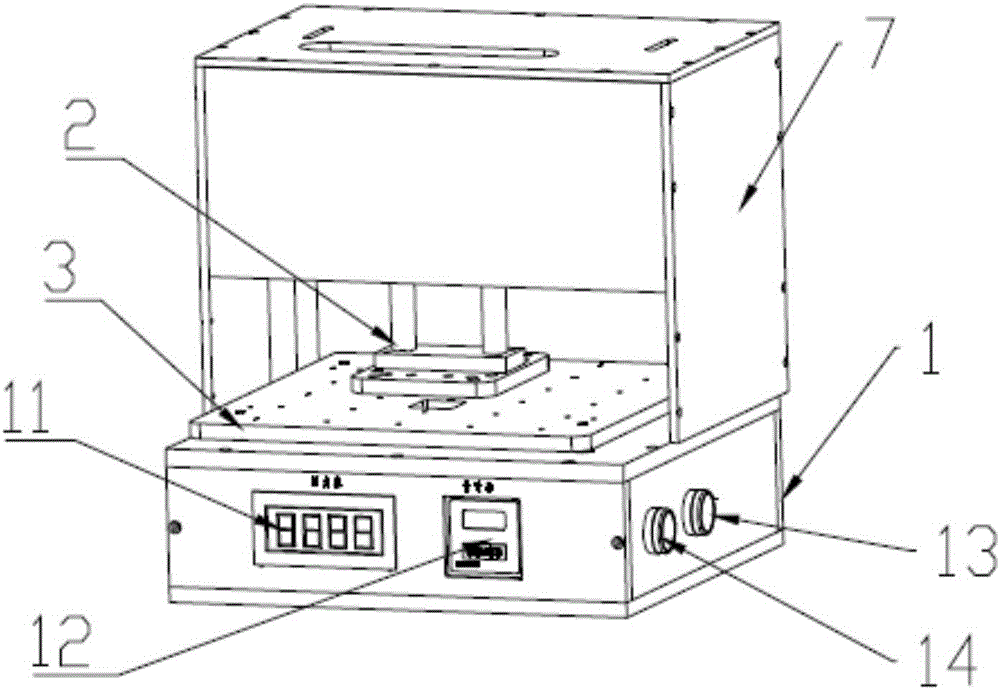

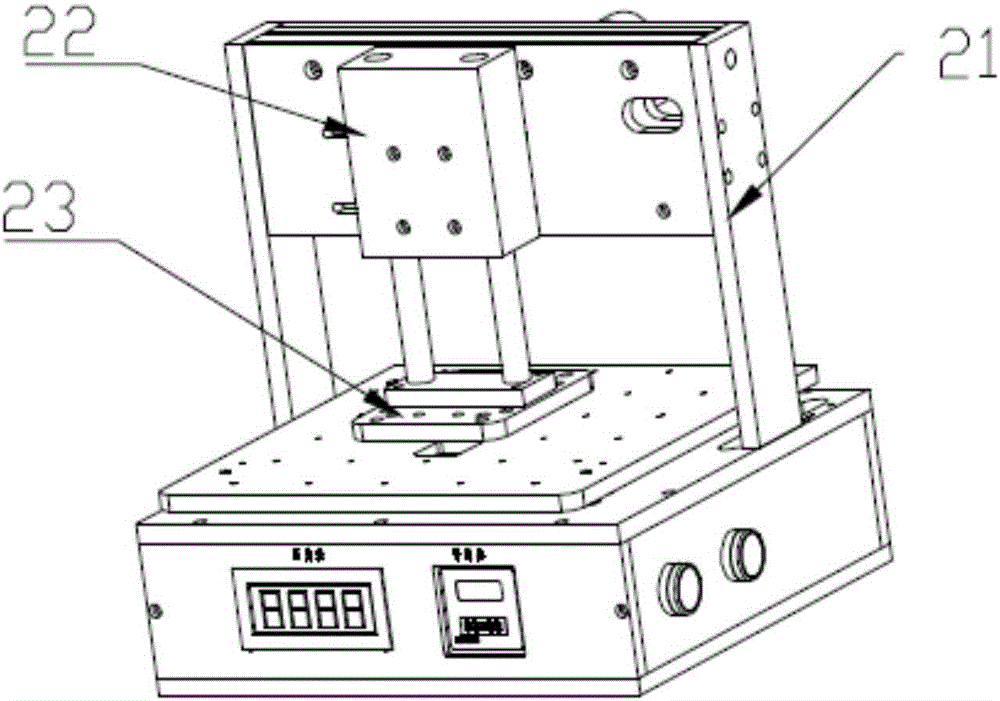

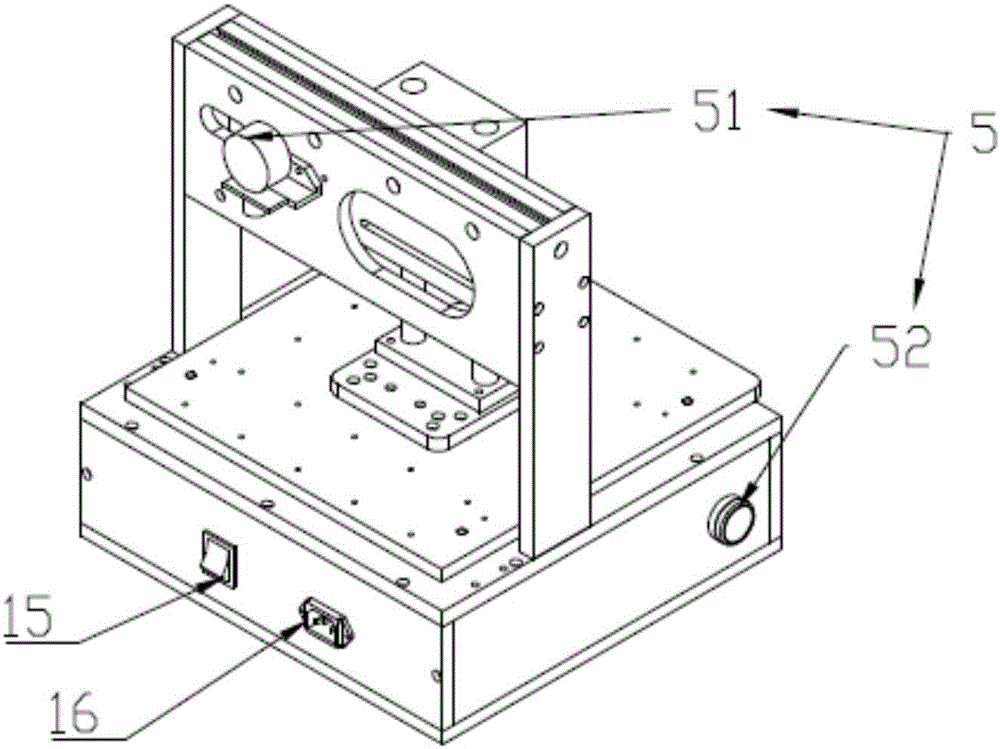

[0033] Please refer to Figure 1 to Figure 3 , figure 1 It is an overall structural view of the universal product assembly press attachment device provided by the embodiment of the present invention, figure 2 and image 3 A view of the internal structure of the press fit device assembled for general purpose products with the protective cover removed.

[0034] In this embodiment, the general-purpose product assembly pressing device includes: an electric control box 1 , a cylinder pressing mechanism 2 , a panel mechanism 3 , a gravity sensor 4 , and an air source adjusting mechanism 5 .

[0035] The electric control box 1 adopts a cuboid structure, including a rectangular top plate and a first side plate, a second side plate, a third side plate and a fourth side plate respectively connected to the top plate and forming a rectangle, wherein the first side plate and the first side plate The two side plates are oppositely arranged, the third side plate and the fourth side plate...

Embodiment 2

[0053] In order to ensure that the product is not damaged while obtaining a good pressing effect, the second embodiment improves the panel mechanism 3 .

[0054] see Figure 4 As shown, the panel mechanism 3 specifically includes a first platform panel 31 and a second platform panel 32 .

[0055] The first platform panel 31 is fixed on the top surface of the electric control box 1, and several guide shafts 311 and contour springs 312 are evenly distributed around the upper surface of the first platform panel 31. 313, for fixing the gravity sensor 4.

[0056] The upper surface of the second platform panel 32 forms a pressure-attached operation area, which is provided with a through hole 321 for the gravity sensor 4 to pass through, and is provided with a fixed position 322 compatible with the photoelectric sensor 6, and the photoelectric sensor 6 fixed in the fixed position 322. The lower surface of the second platform panel 32 is provided with several guide grooves (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com