Deep cleaning equipment for high-strength fiber weftless cloth

A technology for cleaning equipment and high-strength fibers, which is applied in the processing of textile materials, textiles and papermaking, liquid/gas/steam textile processing, etc. To achieve the effect of thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

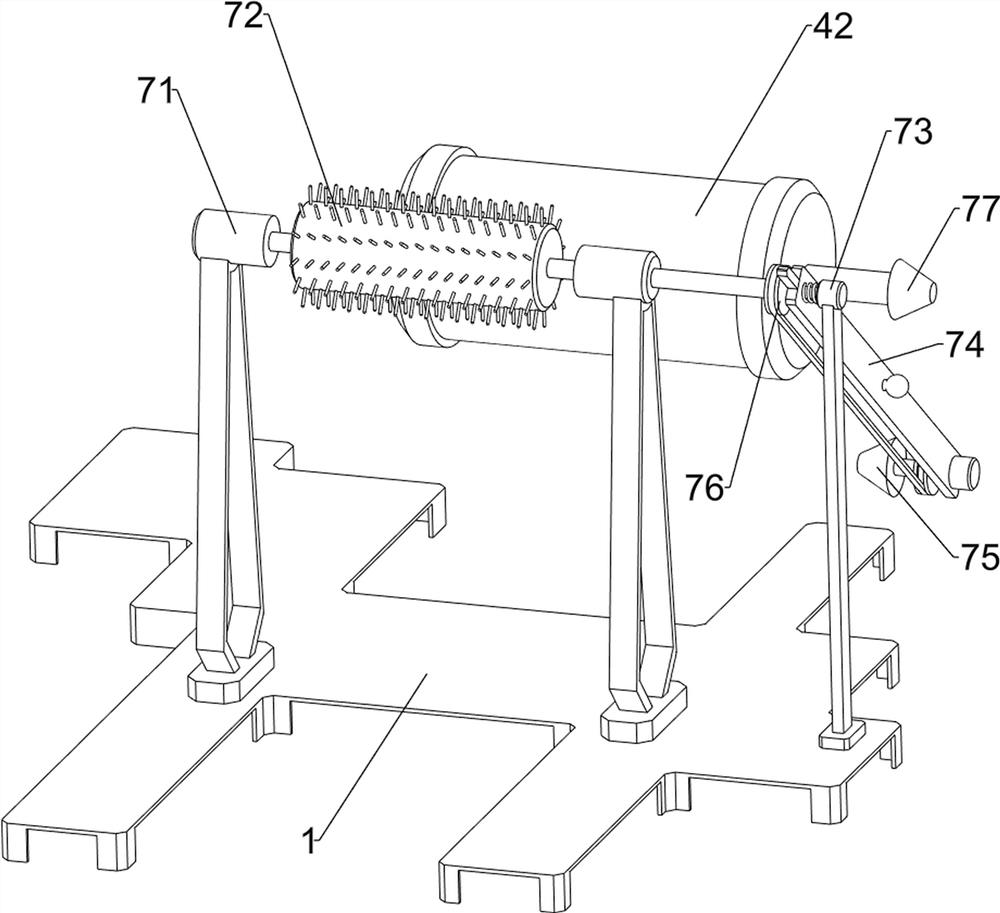

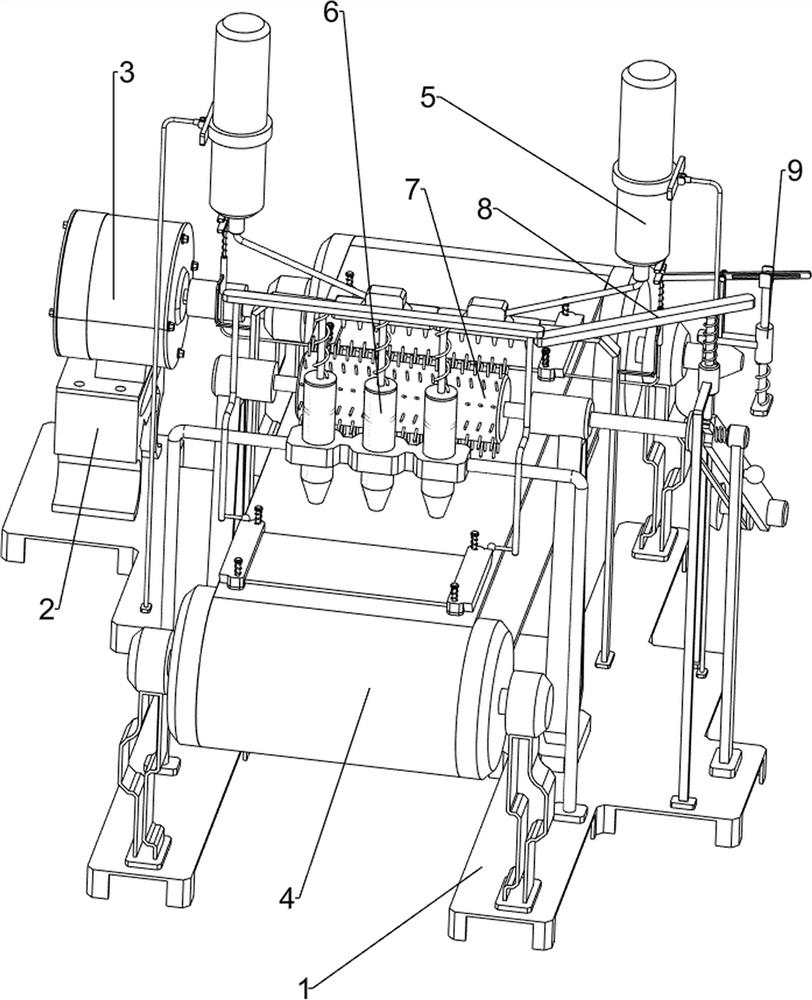

[0063] A deep cleaning equipment for high-strength fiber non-weft cloth, such as Figure 1-8 As shown, it includes a bottom plate 1, a bracket 2, a motor 3, a transmission mechanism 4 and a flushing mechanism 5, a bracket 2 is provided at the left rear part of the top of the bottom plate 1, a motor 3 is provided on the top of the bracket 2, and a transmission mechanism is provided in the middle of the top of the bottom plate 1 4. A flushing mechanism 5 is provided on the back side of the top of the bottom plate 1, and the motor 3 is connected with the transmission mechanism 4.

[0064]When the weft-free cloth needs to be deeply cleaned, the staff will put the weft-free cloth on the transmission mechanism 4. After the weft-free cloth is put into the transmission mechanism 4, the staff will control the motor 3 to rotate clockwise, driving the transmission mechanism 4 to rotate, and the The rotation of the mechanism 4 drives the no-weft part to move backward, and then the staff s...

Embodiment 2

[0066] On the basis of Example 1, such as Figure 2-4 As shown, the transmission mechanism 4 includes a first rotary sleeve 41, a cylinder 42, a conveyor belt 43, a guide plate 44 and a first elastic pressure plate 45, and the first rotary sleeve 41 is symmetrically arranged on the front and rear sides of the top of the bottom plate 1. Between the two first rotary sleeves 41 and between the two first rotary sleeves 41 on the rear side, a roller 42 is rotatably arranged, and a conveyor belt 43 is wound between the front and rear two rollers 42, and the left and right sides of the conveyor belt 43 are uniform. Guide plates 44 are provided, and the number of guide plates 44 is eight. The guide plates 44 are slidably provided with a first elastic pressure plate 45 , and the first rotary sleeve 41 is connected with the motor 3 .

[0067] When the non-weft cloth needs to be deeply cleaned, the staff will move the first elastic pressing plate 45 on both sides upwards, at this time, t...

Embodiment 3

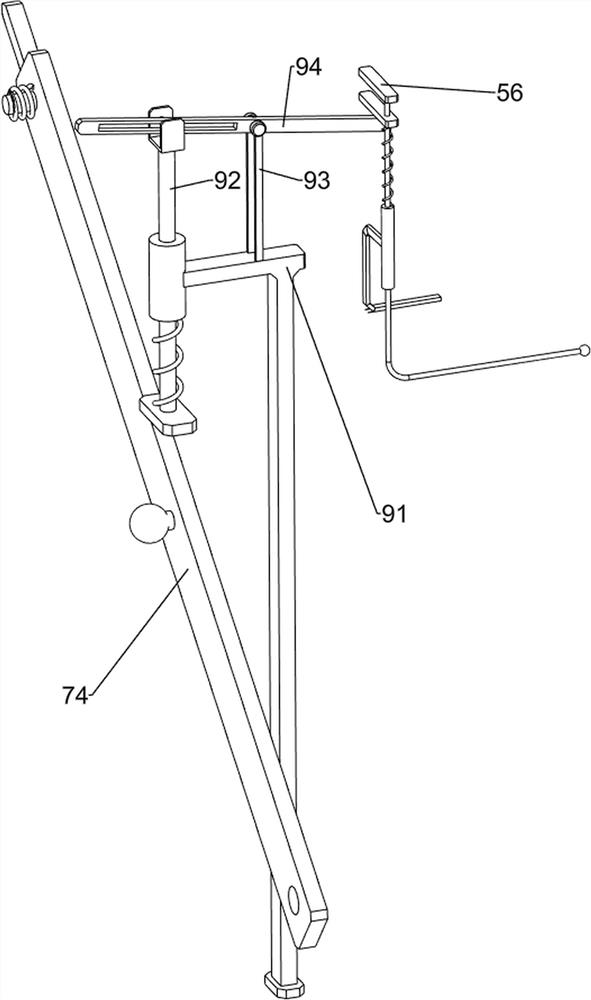

[0071] On the basis of Example 2, such as Figure 5-8 As shown, it also includes a washing liquid spraying mechanism 6. The washing liquid spraying mechanism 6 includes a second fixed sleeve 61, a bucket 62, an elastic pressure column 63 and an extruding rod 64. The top of the bottom plate 1 is evenly provided with a second fixed sleeve 61, the number of the second fixed sleeve 61 is three, the second fixed sleeve 61 is provided with a barrel 62, the top of the barrel 62 is slidingly provided with an elastic pressure column 63, and the left and right sides of the elastic pressure column 63 are provided with extruding rods 64 , the extruding rod 64 cooperates with the first elastic pressing plate 45 .

[0072] The first elastic pressing plate 45 moves backwards to squeeze the extruding rod 64, so that the extruding rod 64 moves downward, and the downward movement of the extruding rod 64 drives the elastic pressing column 63 to move downward, and the elastic pressing column 63 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com