Automatic device for steel pipe hot-dip galvanizing and pickling and control method

An automatic device and hot-dip galvanizing technology, applied in the field of hot-dip zinc pickling, can solve the problems of large health impact, low production efficiency, hidden dangers in corrosion prevention, etc. acid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described now in conjunction with accompanying drawing.

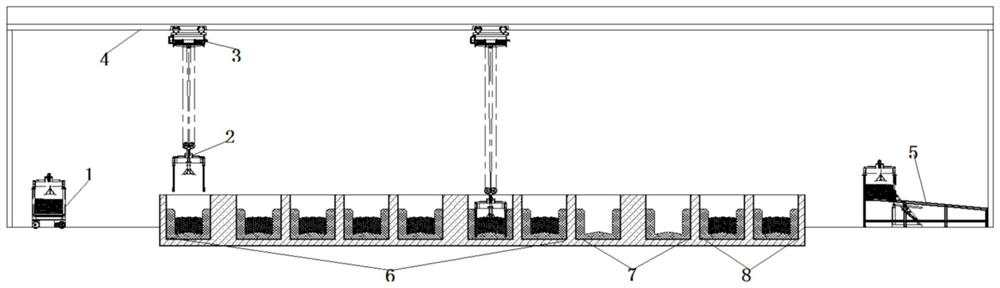

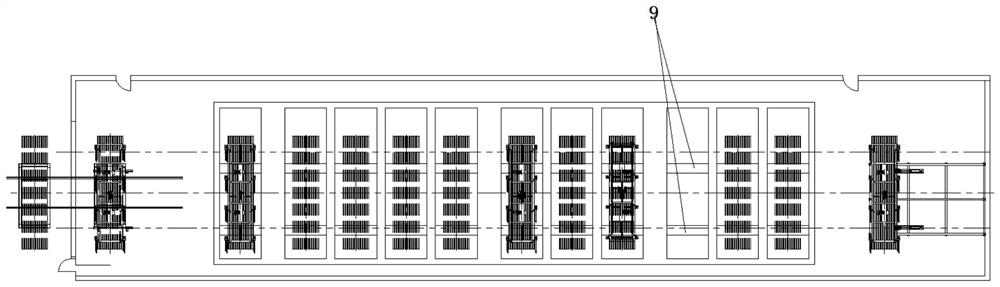

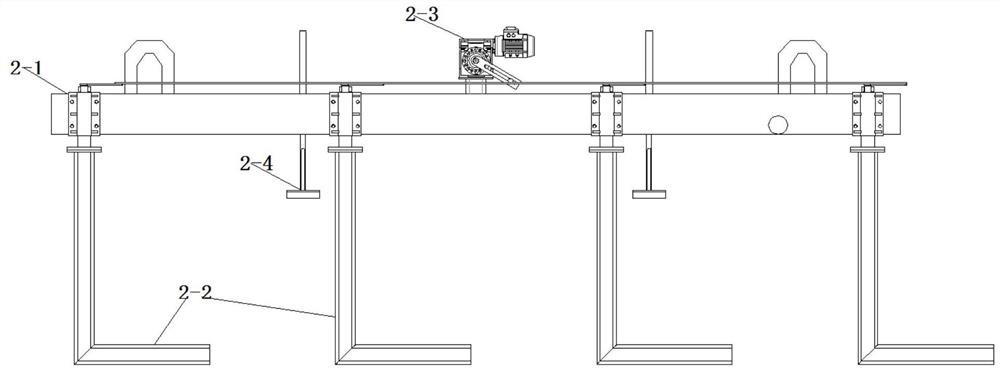

[0039] as attached Figure 1~Figure 2 As shown, the present invention is an automatic device for hot-dip galvanizing pickling of steel pipes, comprising a feeding trolley 1, an automatic hanger 2, an intelligent trolley 3, a track 4, a steel pipe discharging platform 5, a pickling pool 6, The rinsing pool 7, the plating aid pool 8, the track 4 is equipped with a smart car 3, the two ends of the automatic hanger 2 are respectively connected with the smart car 3 by the lifting mechanism 3-4, and the pickling pool is arranged under the track 4 according to the feeding direction 6, rinsing pool 7, plating aid pool 8, combined Figure 11 , Figure 12 , the pickling tank 6, the rinse tank 7, the inner side of the plating aid tank 8 are all provided with a boss 9, the feeding trolley 1 is provided under the feed end of the track 4, and the steel pipe discharge platform is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com