Composite processing equipment for double-layer plastic craft

A compound processing and handicraft technology, which is applied in the field of double-layer plastic handicraft compound processing equipment, can solve problems such as low processing efficiency, scattered processes, and cumbersome equipment, so as to improve compound efficiency, improve functionality and practicability, improve convenience and The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

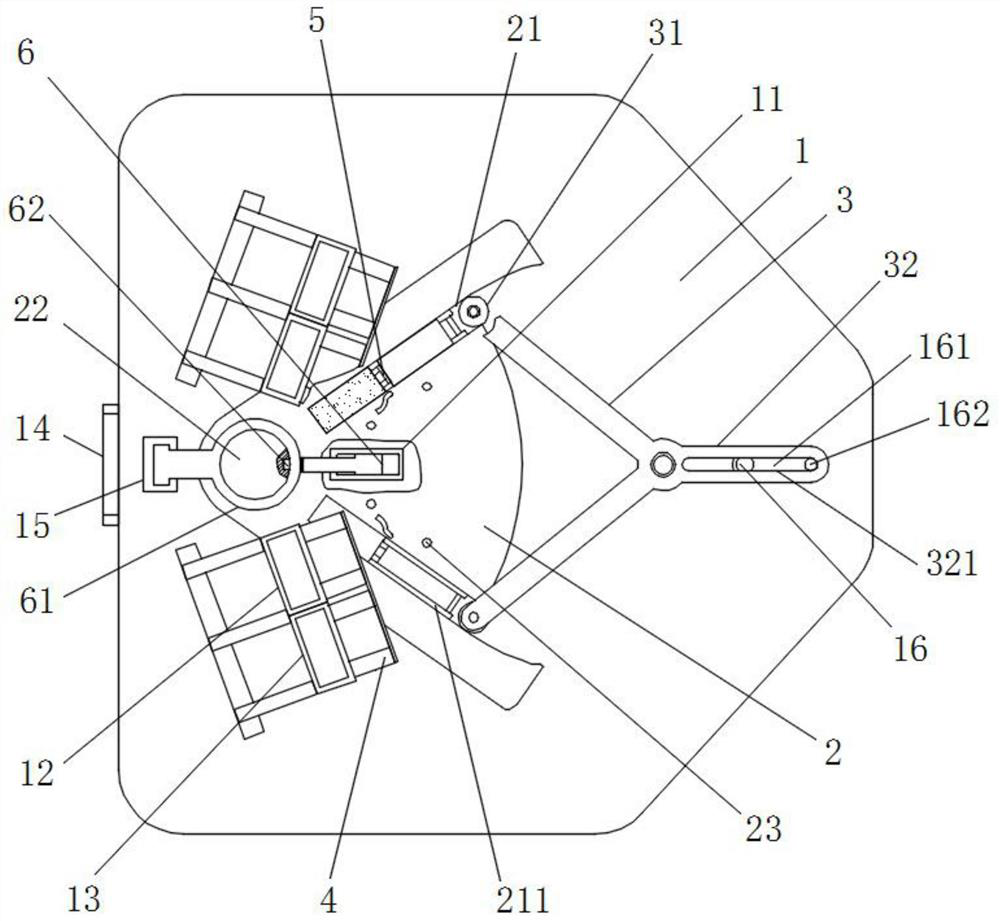

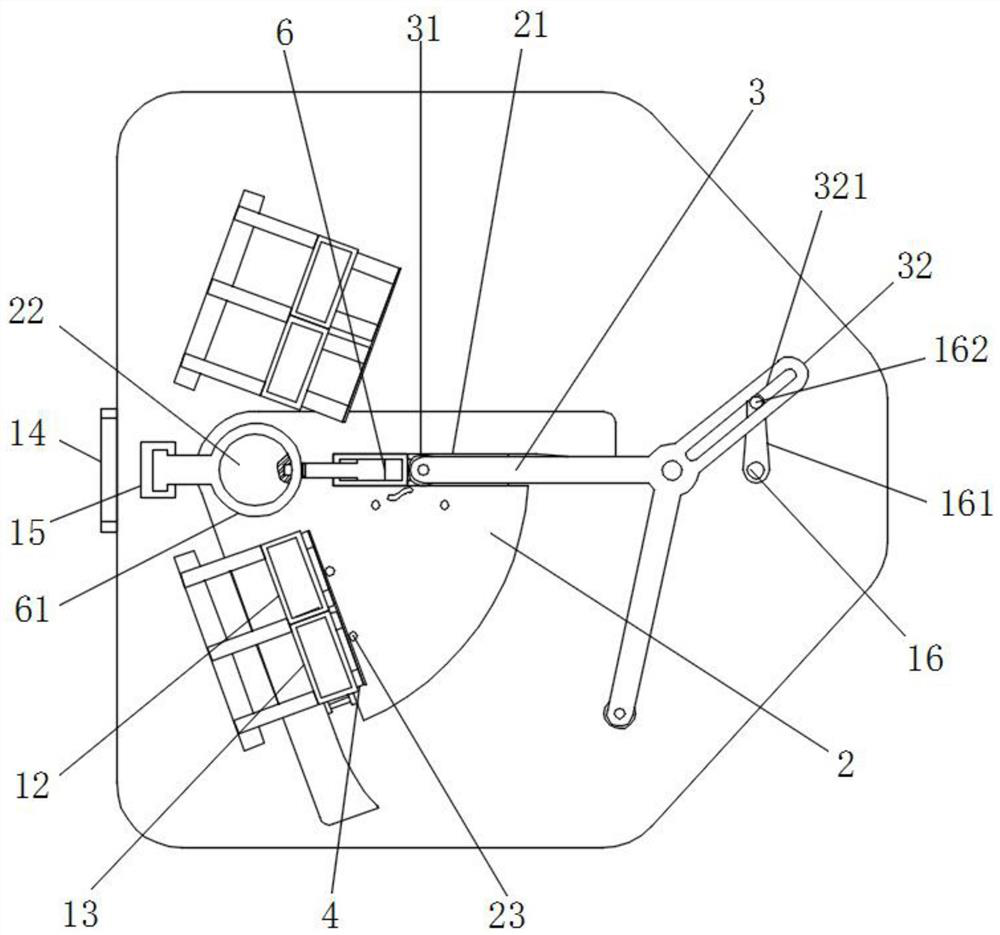

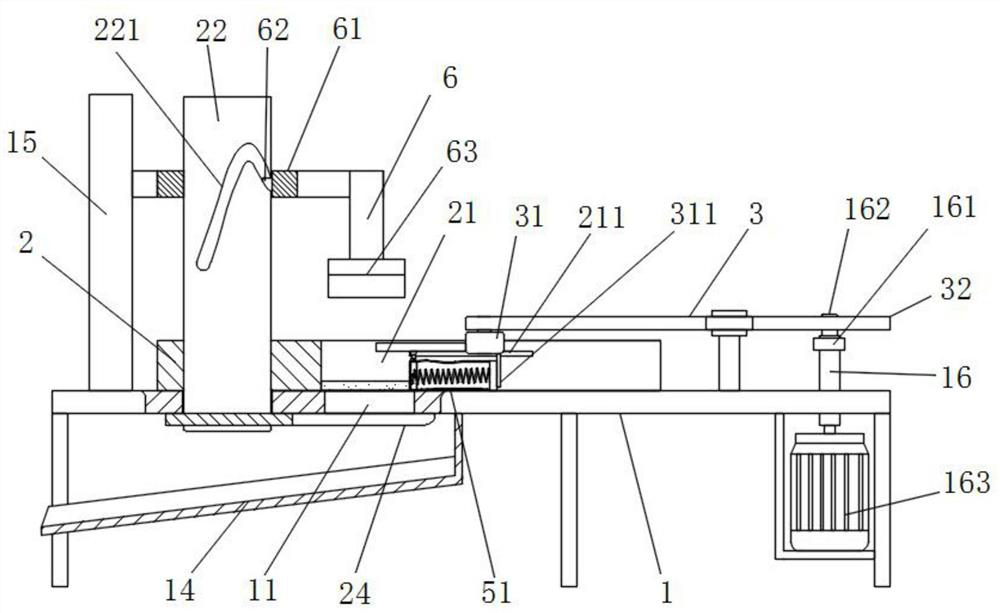

[0031] The implementation mode is specifically: the rocker 161 is controlled to swing continuously by the drive motor 163, and then the swing rod 32 can be driven to swing continuously by the cooperation of the protruding shaft 162 and the movable groove 321, thereby driving the V-shaped swing frame 3 to swing continuously, and when the V-shaped swing During the swinging process of the frame 3, the push wheel 31 can correspondingly enter the corresponding push guide groove 21, and utilize the push guide groove 21 to guide the push wheel 31, so that when the V-shaped swing frame 3 swings, the fan-shaped swing seat 2 is driven to perform Swing synchronously, and by setting the material box 12 on the bottom plate and the material box 13 on the top plate on both sides of the top of the processing table 1, whenever the two pushing guide grooves 21 swing to the limit position to the outside, they will reach the material box 12 on the bottom plate and the bottom of the material box 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com