Metal reflection image identification technology based on edge point self-similarity, and TEDS system

A self-similarity, image recognition technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problem of high false positive rate, and achieve the effect of improving accuracy and solving high false positive rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a metal reflective image recognition based on edge point self-similarity applied on the TEDS system, comprising the following steps:

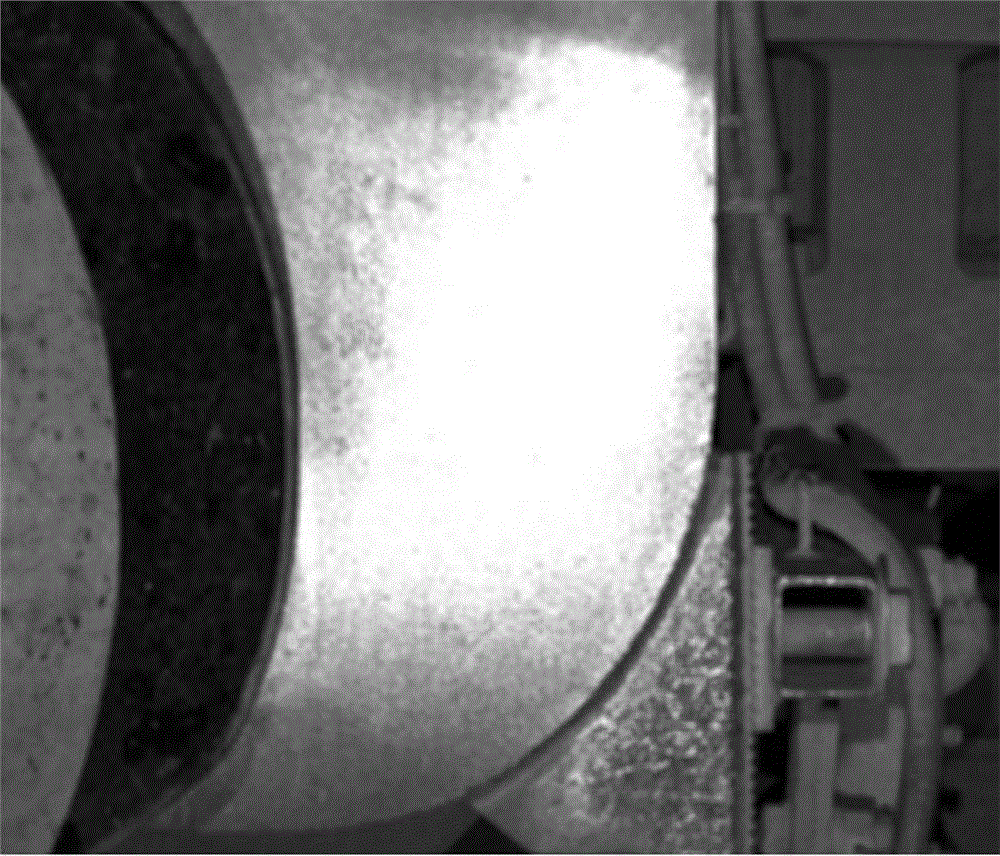

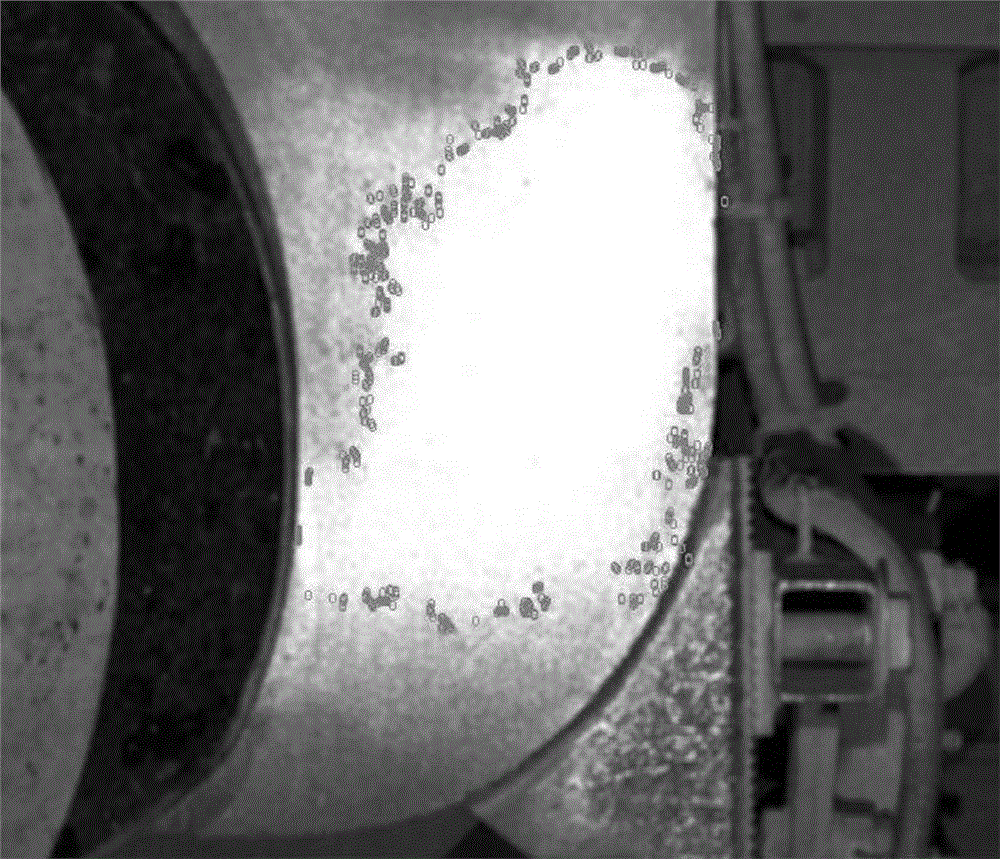

[0038] Step 1: Input the EMU image to be detected in the computer, such as figure 1 For the image shown, use the canny edge detection algorithm to obtain all the edge points of the image; the specific process is as follows:

[0039] 1. Process the EMU image into a grayscale image on the computer;

[0040] 2. Perform Gaussian blur on the grayscale image to reduce the interference of image noise;

[0041] 3. Calculate the gradient value and direction of each pixel in the denoised image;

[0042] 4. Perform non-maximum suppression on the gradient value of each pixel, and initially obtain a set of image edge points; 5. Use a double-threshold method to connect edges, eliminate false edges, fill in edge gaps, and obtain a more accurate set of edge points .

[0043] Step 2: Classify all edge points, the same kind of edge point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com