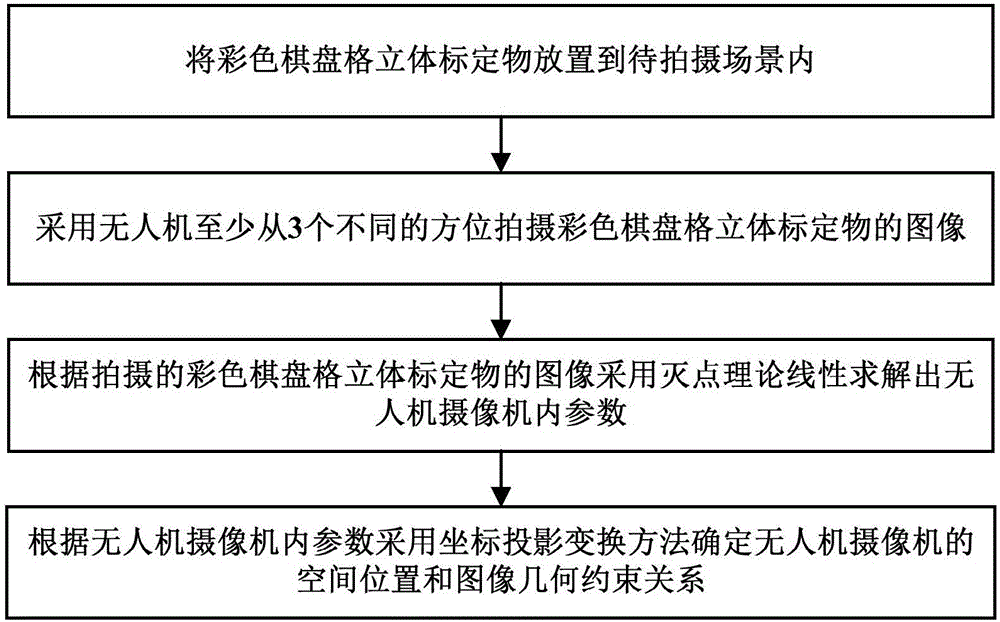

Color stereoscopic calibration object-based unmanned aerial vehicle calibration method and system

A three-dimensional calibration and color three-dimensional technology, applied in the field of computer vision, can solve problems such as cumbersome practical operations, difficult visual recognition errors, limited spatial range of reconstruction, etc., and achieve the effects of convenient use, high detection accuracy, and easy and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Aiming at the problems of difficult accurate measurement, low detection accuracy, inconvenient placement, weak versatility and inconvenient use in the existing technology, the present invention proposes a brand-new calibration method and system for unmanned aerial vehicles. The calibration process of the UAV in the present invention includes two aspects: one is to design a three-dimensional calibration object that is easy to accurately measure, standard and easy to operate, and the other is to provide a method for camera parameter calibration and image geometric constraints. The content of these two aspects will be described in detail below.

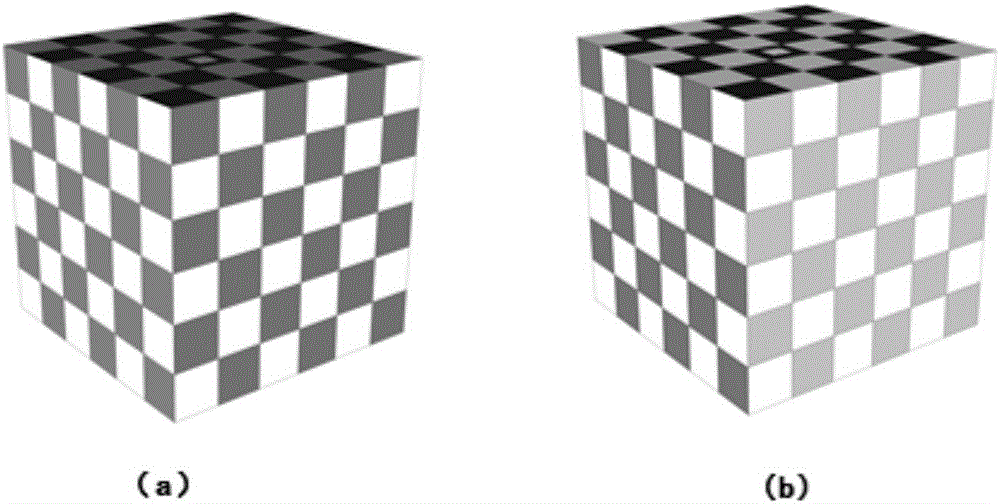

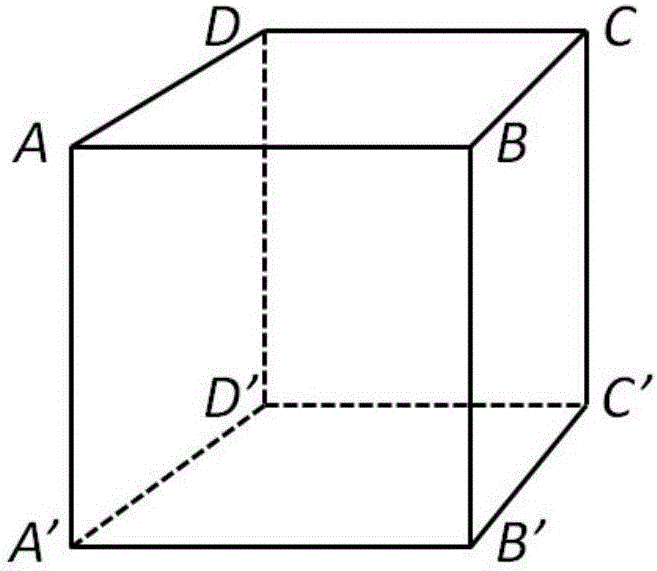

[0067] (1) Design a stereoscopic calibration object

[0068] In order to facilitate the observation of the operator during the shooting operation and the recognition during the post-export photo processing, as well as the setting of different angle ratio constraints in the modeling scene after 3D modeling, the surface of the UAV c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com