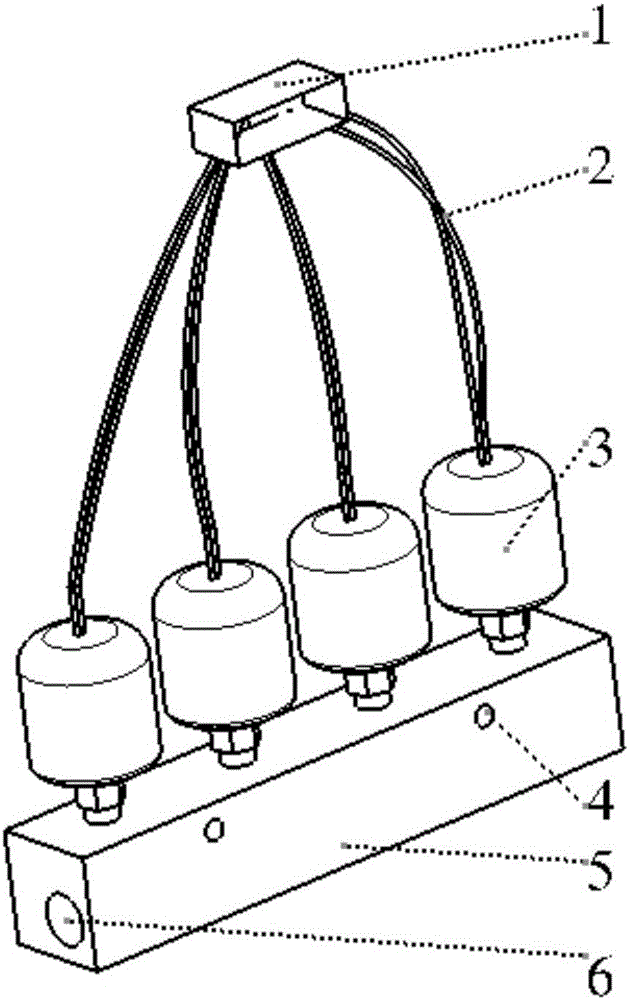

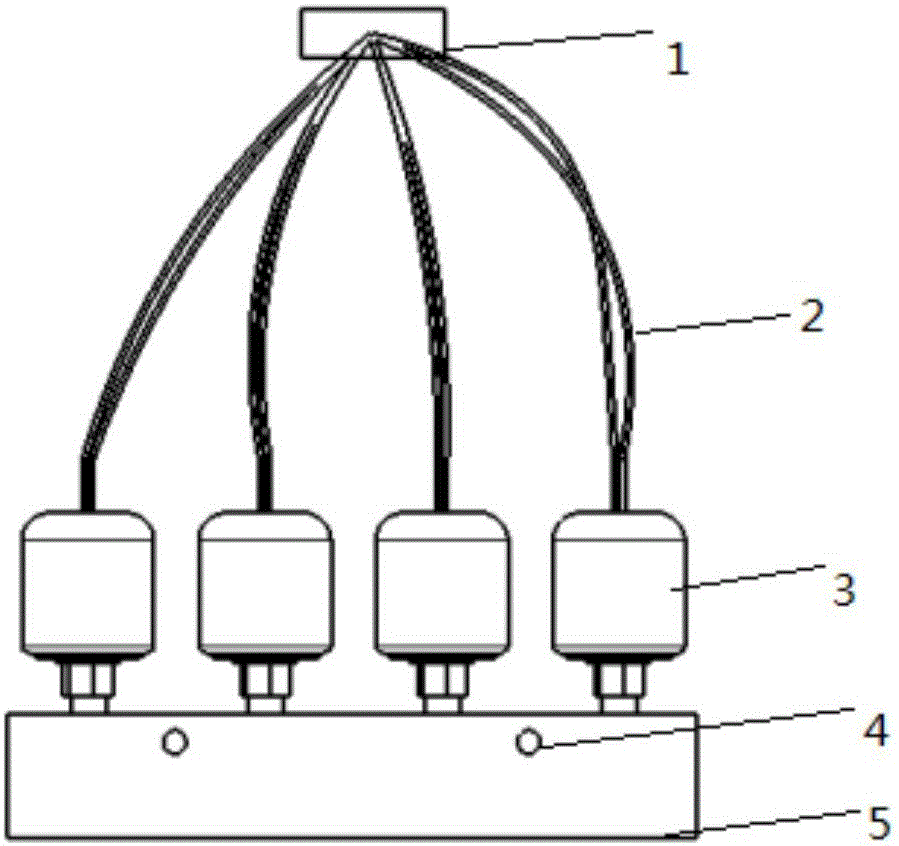

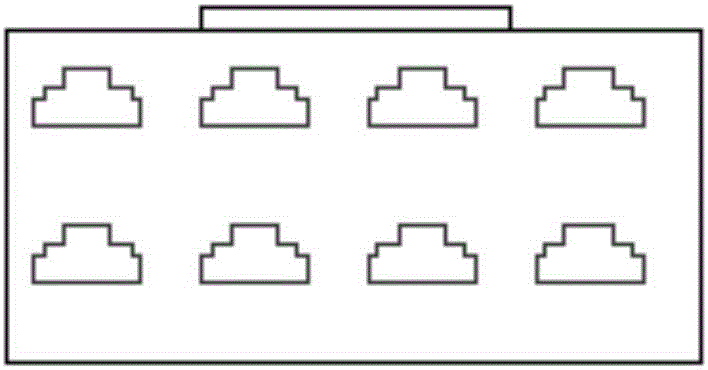

Integrated air pressure switch device

An air pressure switch and air pressure technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of changing installation methods, low efficiency, and low operating efficiency of waterproof and dustproof effects, so as to achieve improved dustproof and waterproof effects and reduce materials The effect of using and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] After extensive and in-depth research, through a large number of screening and experiments, the inventor has developed a new type of integrated air pressure switch device for the first time. When the device is used in the automotive field, it has error-proof design, high production efficiency, is not easy to damage, and is waterproof Excellent dust resistance. The present invention has been accomplished on this basis.

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the present invention is not limited to such embodiments described below, and the technical idea of the present invention can be implemented in combination with other known technologies or other technologies having the same functions as those known technologies.

[0025] In the following description, in order to clearly show the structure and working method of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com