Charged disassembly and assembly tool of bird repeller

A bird repellent and tool technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of reduced power supply reliability, increased high-altitude operation coefficient, unfavorable economic benefits, etc., to prevent screws from falling, reduce friction, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

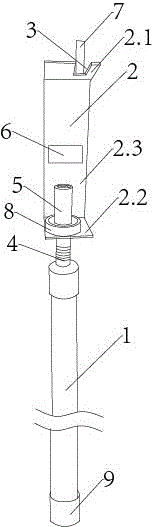

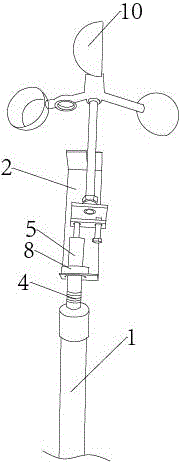

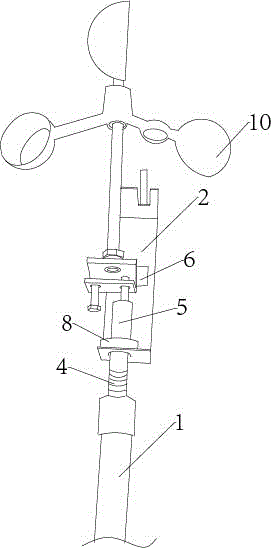

[0017] Such as Figure 1-3 As shown, it is an embodiment of a live disassembly tool for a bird repellent of the present invention, including an insulating rod 1 and a bearing seat 2, the insulating rod 1 passes through the disassembly hole at the bottom of the bearing seat 2 and is connected to the bearing seat 2, and the bearing seat 2 is "匚" shape, bearing seat 2 includes upper plate 2.1 and lower plate 2.2 arranged in parallel, the rear edge of upper plate 2.1 and the rear edge of lower plate 2.2 are connected by intermediate connecting plate 2.3; the front edge of upper plate 2.1 is provided with positioning U-shaped groove, and the U-shaped groove is close to the right side of the upper plate 2.1; the lower plate 2.2 is provided with a disassembly hole, and the disassembly hole is close to the left side of the lower plate 2.2; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com