Conical magnetic suspension dual-passage switch reluctance machine and control method

A technology of switched reluctance motor and reluctance motor, which is applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of unfavorable system simplification and reliability, low integration, large eddy current loss and temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical scheme of a conical magnetic levitation dual-channel switched reluctance motor and its control method of the present invention will be described in detail below in conjunction with the accompanying drawings:

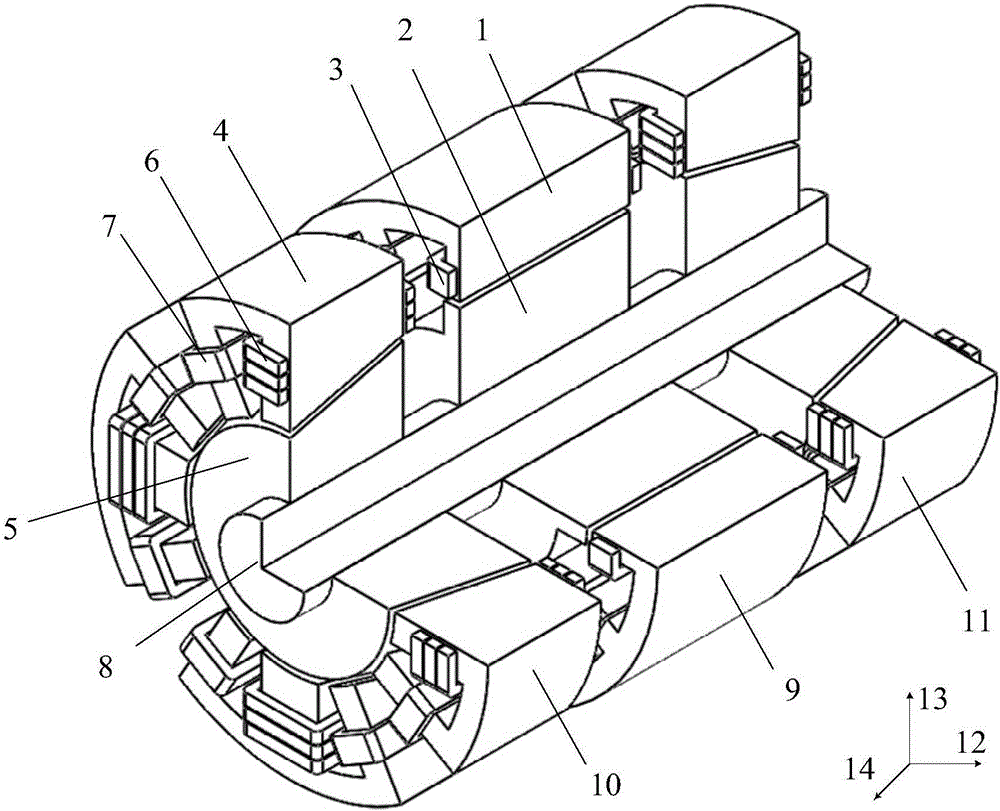

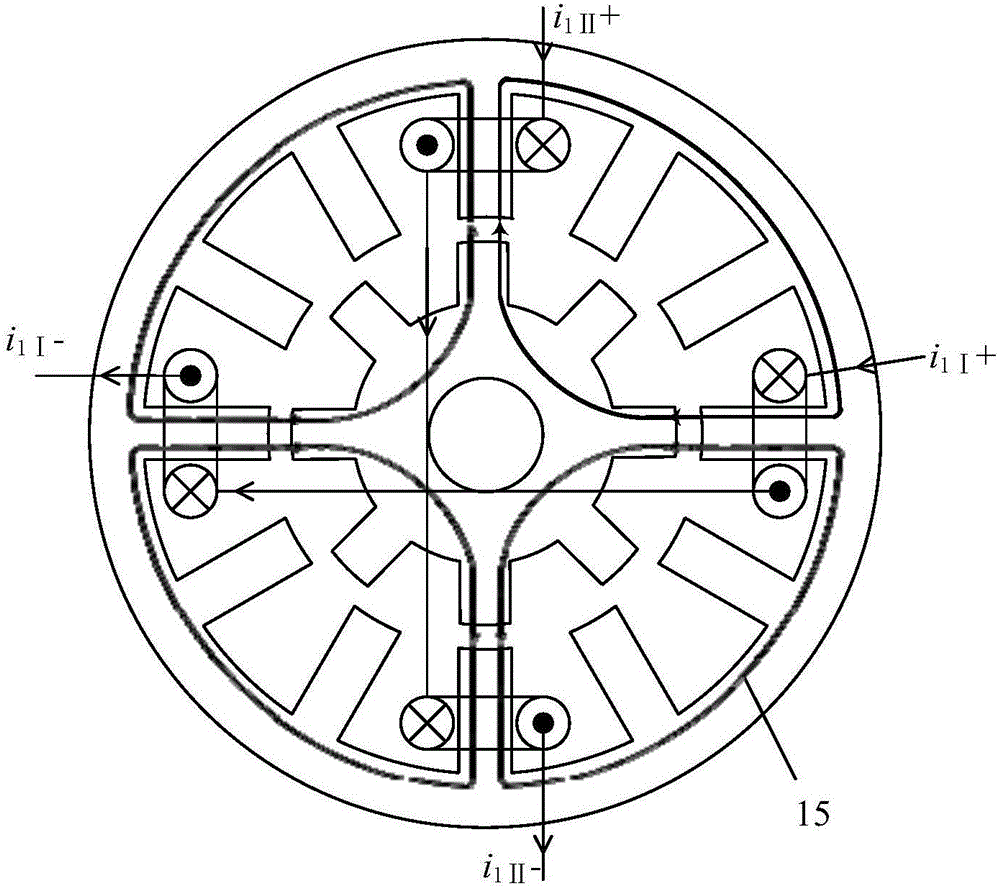

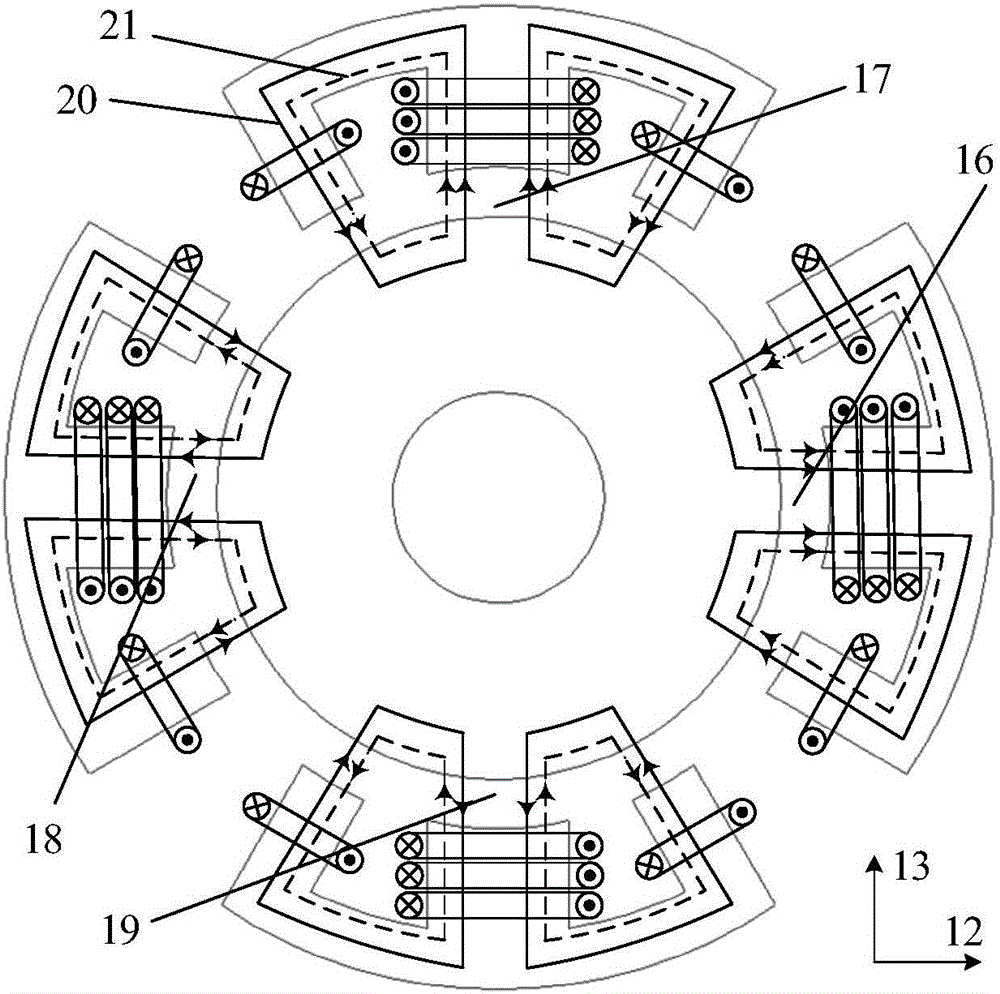

[0062] Such as figure 1 Shown is a three-dimensional structural schematic diagram of the embodiment 1 of the conical magnetic levitation dual-channel switched reluctance motor of the present invention, wherein, 1 is the stator of the reluctance motor, 2 is the rotor of the reluctance motor, 3 is the winding of the reluctance motor, and 4 is the conical Stator, 5 is conical rotor, 6 is bias winding, 7 is radial levitation winding, 8 is rotating shaft, 9 is 12 / 8 pole switched reluctance motor, 10 is conical magnetic bearing I, 11 is conical magnetic bearing II, 12, 13, and 14 are the positive directions of the coordinate axes in the x, y, and z directions, respectively.

[0063] The conical magnetic levitation dual-channel switched reluctance motor in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com