Device For Connecting Strip Ends Of Steel Strips

A strip and steel technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of lowering the quality of final products, lowering the quality of intermediate products, lowering the quality of continuous strip processing, etc. Effects of calibration, compact design, reliable location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A preferred embodiment is described below with reference to the drawings. In this case, identical, similar or identically acting elements are identified by the same reference numerals in different figures and a repeated description of these elements is partially omitted in order to avoid a redundant description.

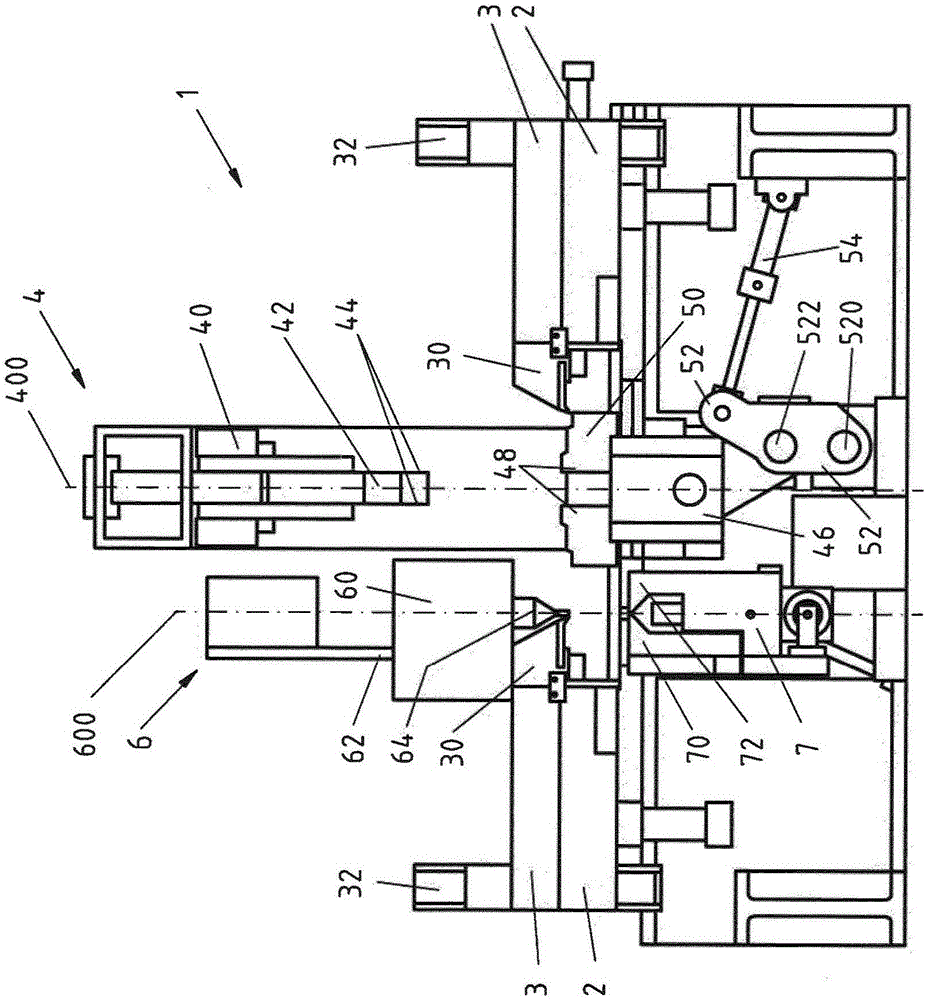

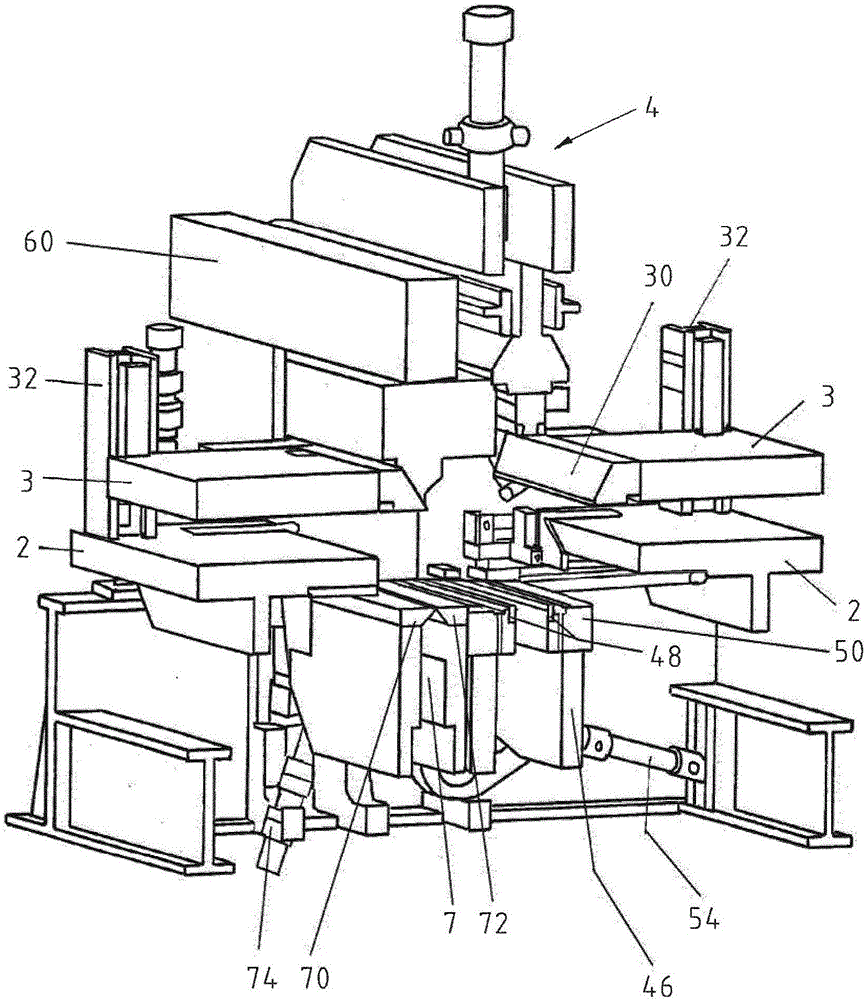

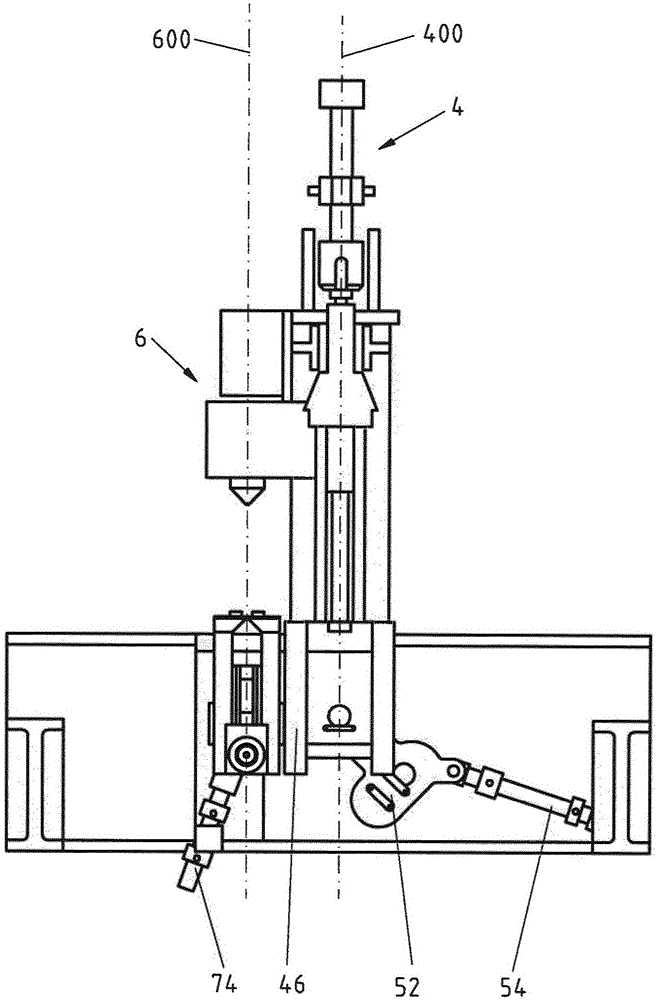

[0029] figure 1 A device 1 for joining strip ends is shown, which device is provided with a shear 4 . An upper blade support 40 with an upper blade 44 is arranged above the horizontal plane of the transport strip. The upper blade holder 40, which includes the upper blade 44 in the upper blade case 42, is movable along its vertical axis by a hydraulic system. Arranged below the upper blade holder 40 along the vertical axis is a lower blade holder 46 comprising a lower blade case 50 with a lower blade 48 . The upper blade case 42 can be lowered by the upper blade holder 40 and closed with the lower blade case 50 in the cutting position.

[0030] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com