Method for manufacturing plastic pedelec frames, and accordingly manufactured pedelec frame

A technology for electric bicycles and frames, applied in the direction of bicycle racks, bicycle accessories, applications, etc., can solve problems such as lack of material load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

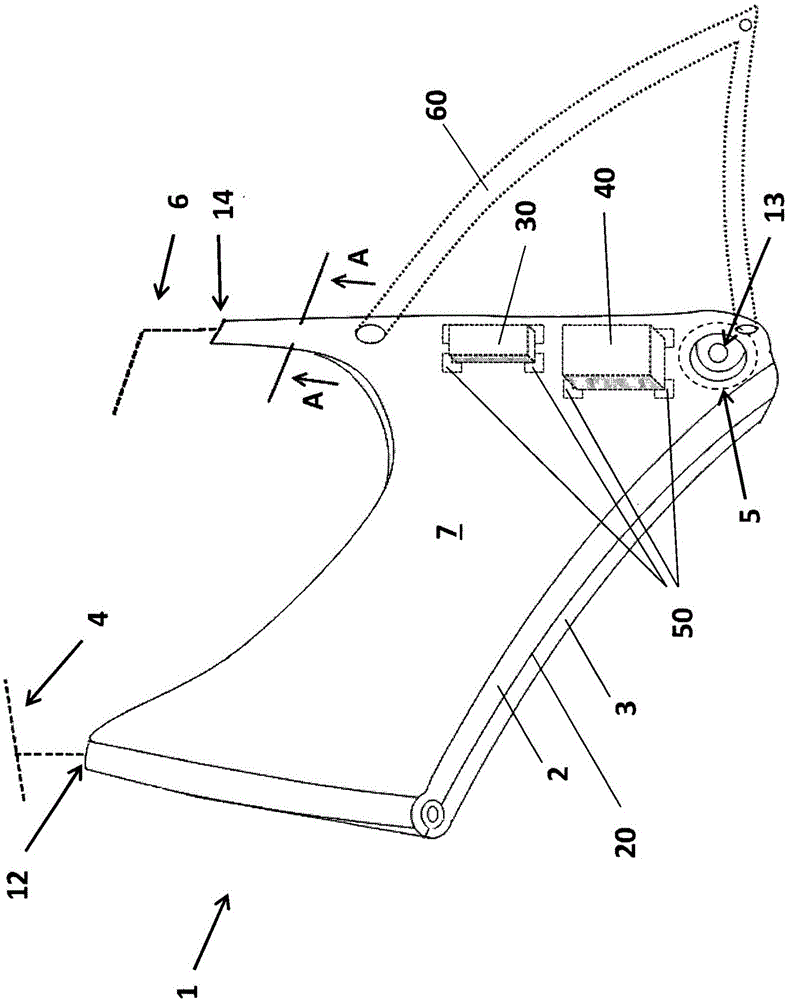

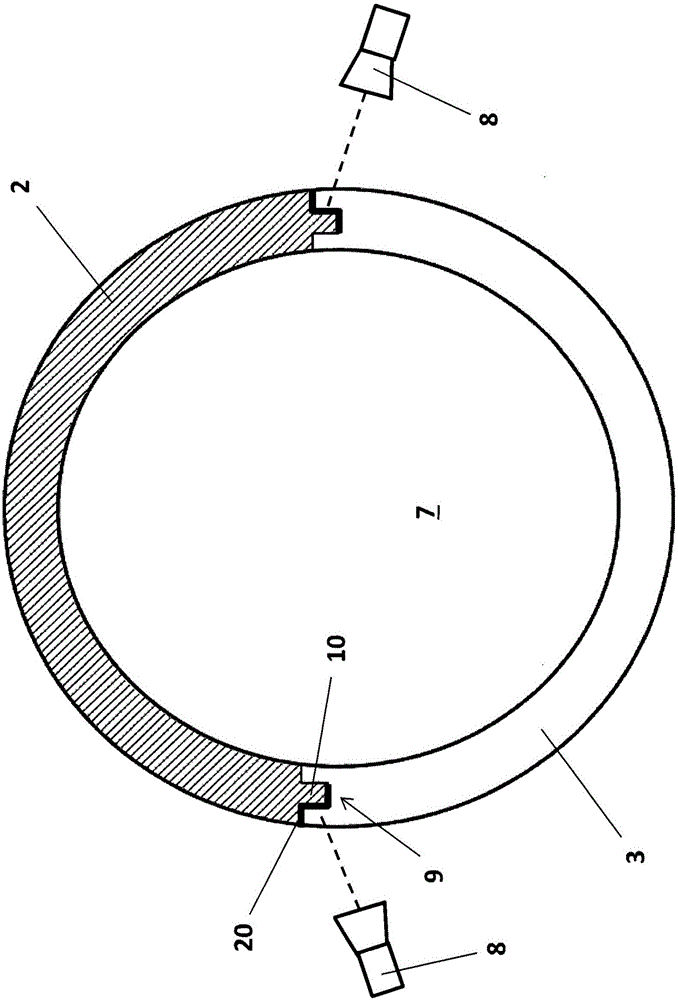

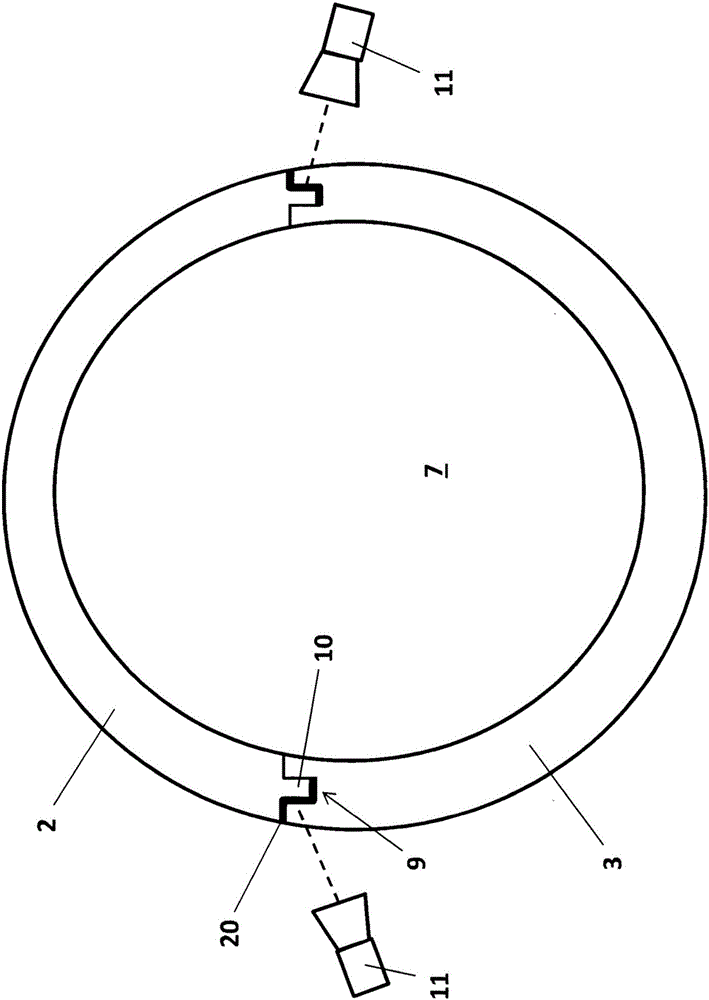

[0029] figure 1 An electric bicycle frame 1 according to the invention is shown, which is produced by joining together two corresponding plastic housing halves 2 , 3 . The electric bicycle frame 1 has a receptacle 12 for the handlebar 4 , a receptacle 13 for the pedal support 5 and a receptacle 14 for the driver's seat 6 . The handlebar 4, the pedal support 5 and the driver's seat 5 are only on the figure 1 shown in . A resiliently configurable rear structure 60 , shown in dashed lines, is fastened to the electric bicycle frame and serves to accommodate the (not shown) rear wheel of the electric bicycle. The two housing halves 2 , 3 consist of a fiber-reinforced thermoplastic containing semiaromatic polyamide. The joining together of the two housing halves 2 , 3 forms an inner cavity 7 which accommodates the battery 30 of the electric bicycle, the electric motor 40 and the pedal support 5 . The joining of the plastic housing halves 2 , 3 also enables the battery 30 , the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com