Heat- and light-curable coating composition and coating film formation method, water pressure transfer method

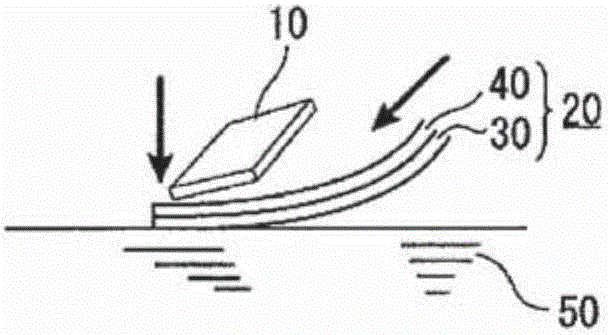

一种水压转印、光热固化的技术,应用在聚脲/聚氨酯涂料、涂层、装饰艺术等方向,能够解决涂膜耐油酸性、耐乳酸性耐日晒性等耐化学性包装性差、装饰层与转印基材粘合性差、没有得到包装性和耐化学性等问题,达到缩短生成工序、实现美观性和耐用性、粘合性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

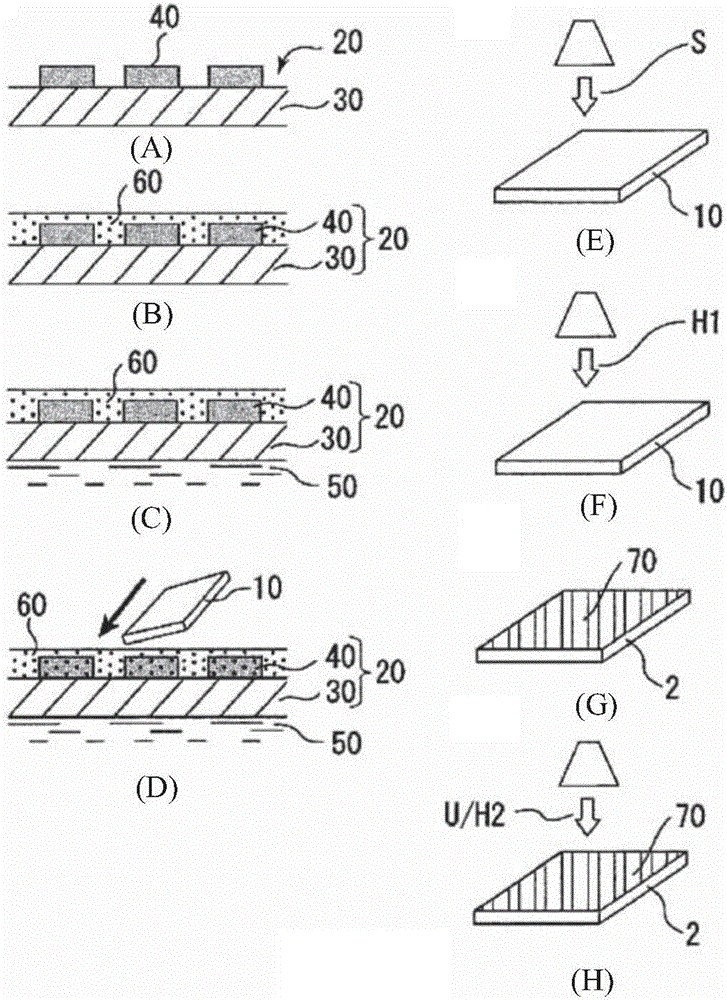

Method used

Image

Examples

Embodiment 1~15、 comparative example 1~9

[0121] In the present examples and comparative examples, the following hydraulic transfer film, active agent composition, and transfer substrate are used to have a decorative layer obtained by hydraulically transferring the printed pattern layer of the hydraulic transfer film: Form a protective film on the surface of plastic molded products and evaluate its characteristics.

[0122] (1) Water pressure transfer film

[0123] For the water pressure transfer film, "G5100trustwalnut 4C" previously licensed by Taica Corporation was used. In addition, on the transfer surface of the polyvinyl alcohol (PVA) film, it is formed by using a solvent-based ink composed of a mixed system of a pigment and a synthetic resin, and a printed pattern layer (in a state where the solvent component is volatilized and removed) by gravure printing to implement a texture pattern. The hydraulic transfer film.

[0124] (2) Active agent composition and coating conditions

[0125] In the Examples and Com...

Embodiment 16~34

[0163] (Examples 16-34, Comparative Examples 10-14)

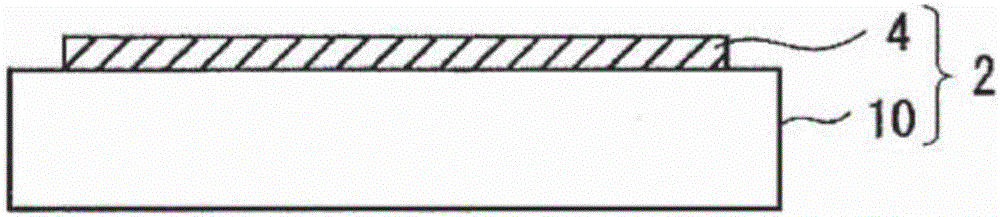

[0164] In this example and comparative example, the coating composition of each example and comparative example was spray-coated on the surface of the ABS resin molded article, and the coating layer was formed so that the film thickness after hardening may become 25 ± 5 micrometers. Then, after heating and pre-curing at an ambient temperature of 80°C for 5 minutes, the cumulative light intensity of irradiation is 1000mJ / cm 2 The ultraviolet rays were further cured by heating at an ambient temperature of 80° C. for 10 minutes to form a coating film.

[0165] The performance of the above-mentioned coating film was evaluated according to the above-mentioned method. Table 4 shows the evaluation results of the coating films.

[0166] [Table 4]

[0167]

[0168] According to the results in Table 4, it can be seen that within the specified blending range, the results of the examples containing acrylic polyol resins, photocur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com