Preparation method of hydrodemetallization catalyst

A technology for hydrodemetallization and catalyst, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., to achieve the effects of increased content, increased service life, and reduced acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

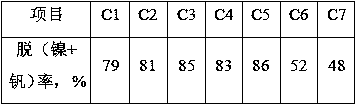

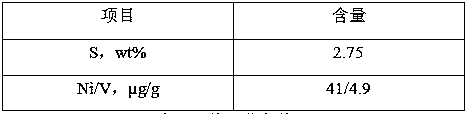

Examples

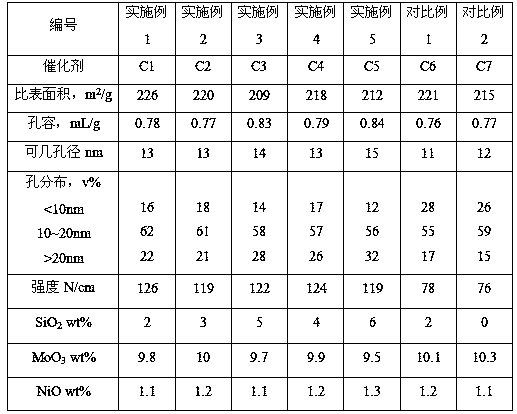

Embodiment 1

[0023] Take by weighing 25 grams of carbon black powder and place it in a spray-soaked rolling pan, and in a rotating state, spray and immerse the carbon black powder in the rolling pan in an unsaturated ethanol containing 2 grams of silicon dioxide in an unsaturated spraying manner. Solution 7.5ml. The impregnated carbon black powder is fully mixed with 150 grams of pseudoboehmite (produced by Wenzhou Jingjing Alumina Factory, with an alumina dry basis content of 65%) and 2 g of scallop powder, and an appropriate amount of 2 g of acetic acid is added to the above materials The aqueous solution is kneaded evenly and extruded into strips. The molded wet material was dried at 110°C for 8 hours. The dried material is placed in a tube furnace, and nitrogen is introduced into the tube furnace to fill the entire furnace with nitrogen, roasted at 400°C for 6 hours, then vented with nitrogen and fed into air, and roasted at 500°C for 6 hours to obtain silicon-containing oxide Alumin...

Embodiment 2

[0025] With embodiment 1, difference: the add-on of carbon black powder is 20 grams, what used when spraying and soaking carbon black powder is the ethanol solution of the methyl orthosilicate of 7ml containing silicon dioxide 3 grams. The calcination temperature under nitrogen atmosphere was 350°C. Catalyst C2 was prepared, and the properties of the catalyst are shown in Table 1.

Embodiment 3

[0027] With embodiment 1, difference: the add-on of carbon black powder is 35 grams, what used when spraying and soaking carbon black powder is the ethanol solution of 14ml containing the butyl orthosilicate of silicon dioxide 5 grams, the roasting under nitrogen atmosphere The temperature is 450°C. Catalyst C3 was prepared, and the properties of the catalyst are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com