Method for determining printing three-primary color density

A technology of three primary colors and densities, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problem that the chromaticity value of the secondary color deviates from the standard, and does not take into account the unreasonable color effect of the secondary color, primary color and secondary color. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

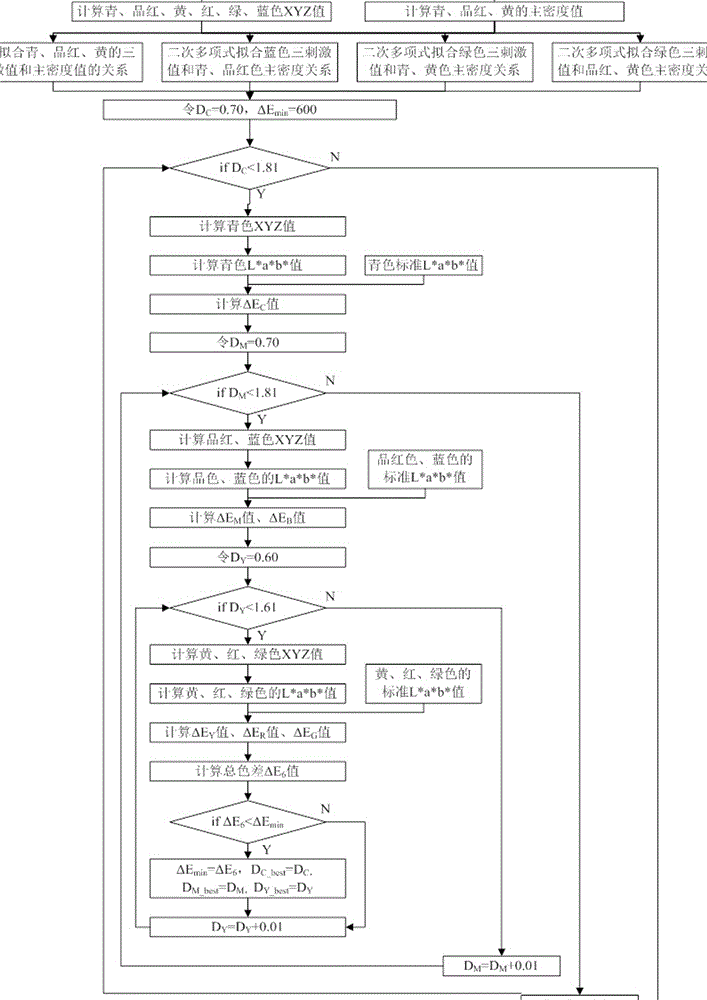

[0034] A method for determining the density of the three primary colors of printing provided by the present invention will be further described in conjunction with the accompanying drawings.

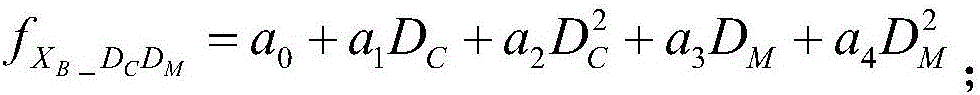

[0035] In the printing production process, in order to improve production efficiency through the division of labor and at the same time restore the color of the original manuscript correctly, it is necessary to carry out quality control in accordance with standardized requirements throughout the production process. Standardized printing production requires that the chromaticity values of primary colors such as cyan, magenta, and yellow and secondary colors such as red, green, and blue be as close as possible to the standard chromaticity value requirements. For a given paper and ink, the chromaticity values of primary colors such as cyan, magenta, and yellow vary with the densities of cyan, magenta, and yellow; while secondary colors such as red, green, and blue vary due to the overpri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com