Horizontal moving device of yarn holder crossbeam

A technology of a horizontal moving device and a yarn device, which is applied to textiles and papermaking, etc., can solve the problems of prolonging the doffing time, increasing the structural complexity of the doffing device, and the complex action process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

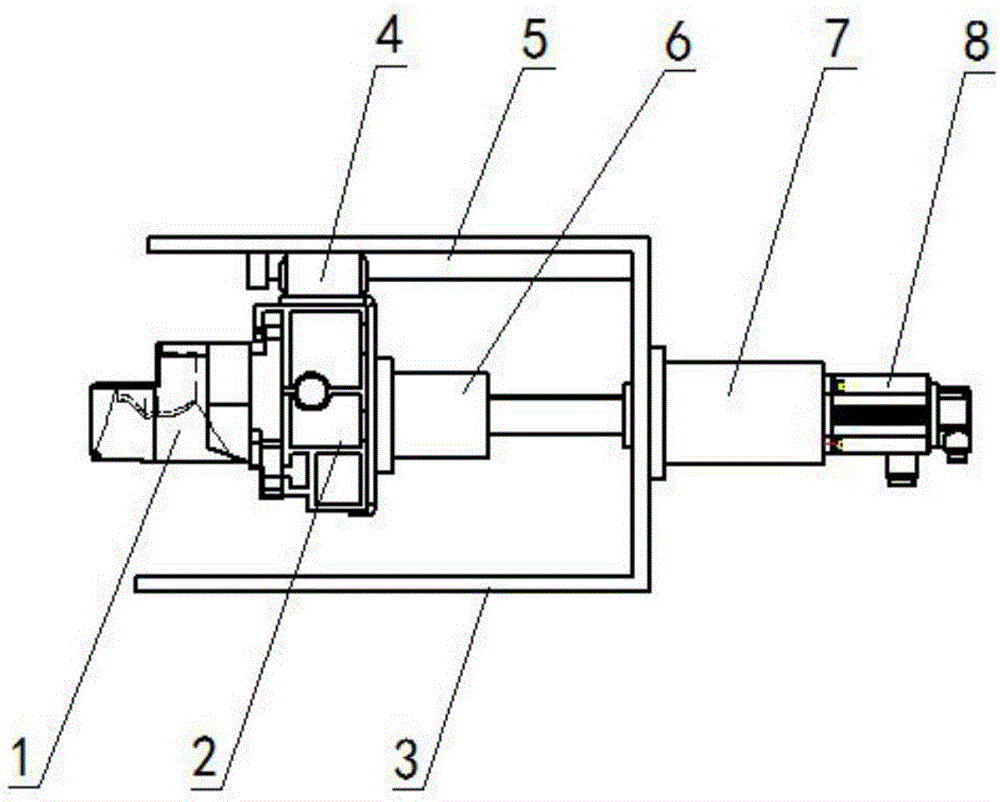

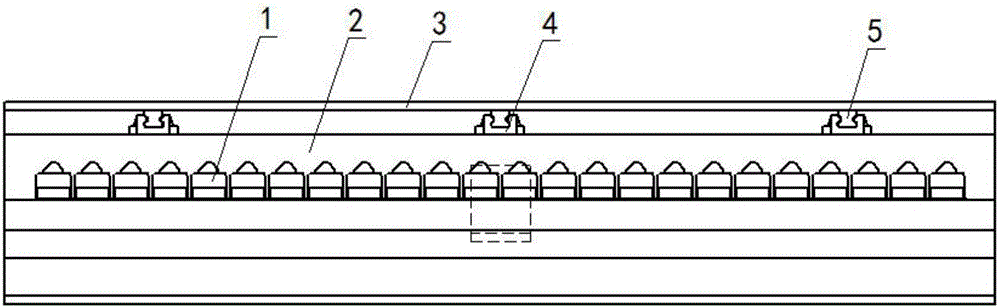

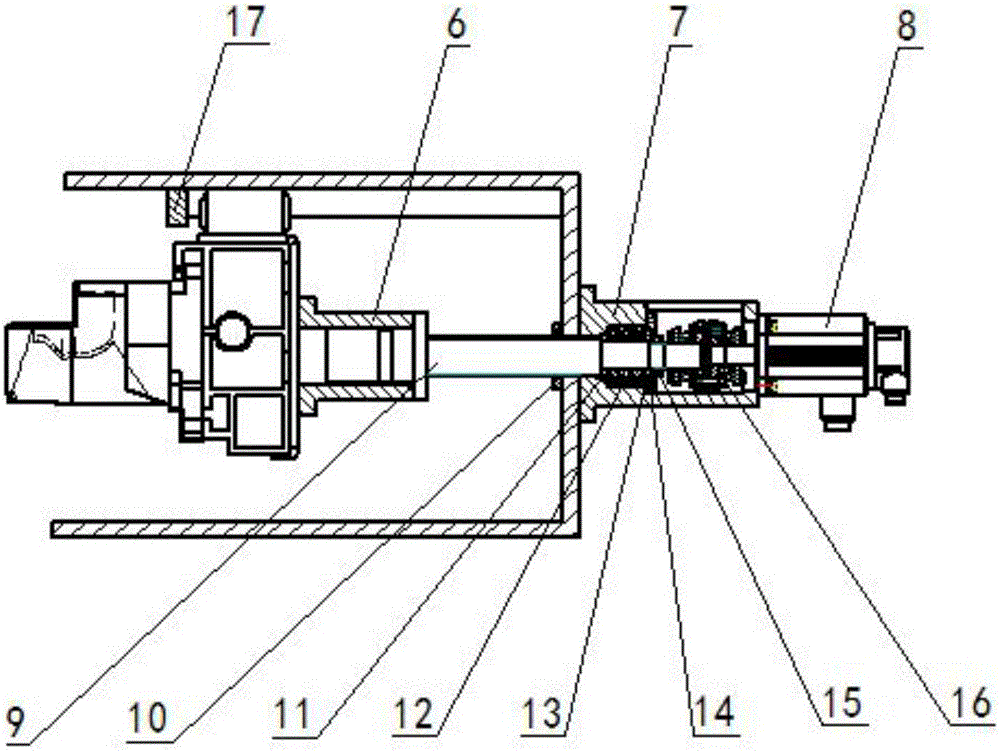

[0015] Such as figure 1 , figure 2 with image 3 As shown, a horizontal moving device for a yarn holding device crossbeam includes a yarn holding device 1, a yarn holding device crossbeam 2, a yarn holding device beam support frame 3, a slider 4, a linear guide rail 5, a front support 6, a rear support 7, a servo Motor 8, ball screw pair 9, buffer pad 10, spacer sleeve 11, paired angular contact ball bearing 12, sleeve 13, flange plate 14, lock nut 15, diaphragm coupling 16, limit block 17, grip Yarn device 1 is installed on the beam 2 of the yarn holder, three sliders 4 are installed above the beam 2 of the yarn holder, three linear guide rails 5 are installed above the inner side of the beam support frame 3 of the yarn holder, three sliders 4 and 3 The linear guide rails 5 are installed together; the front bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com