A kind of steel casing device convenient for recycling

A steel casing and casing technology, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problem that the corrugated web cannot be assembled into a steel casing, the corrugated web is lifted out, and the processing length is too long, etc. problems, to achieve the effect of convenient fixing and recovery of steel casing, reducing construction difficulty and appropriate height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

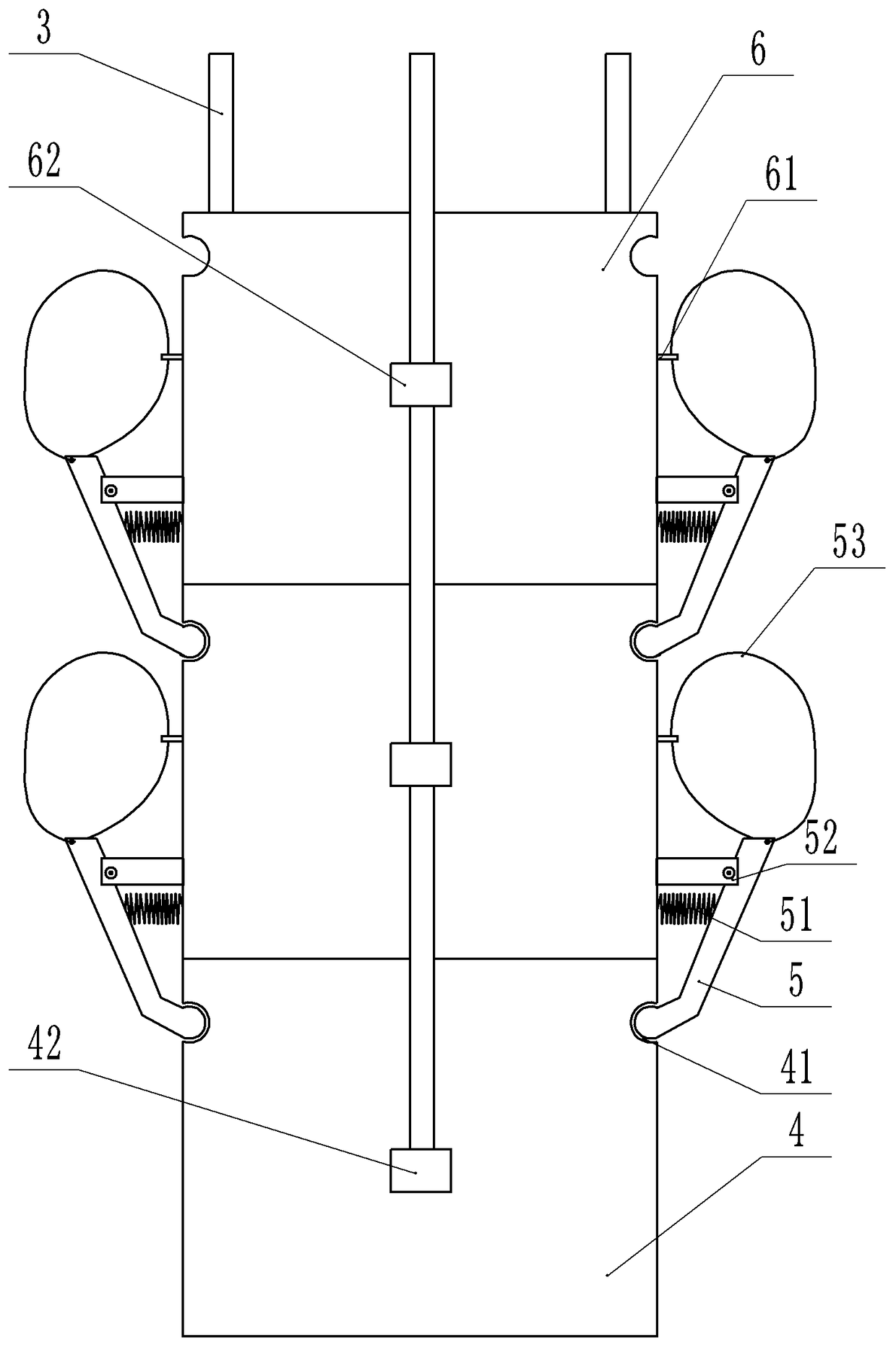

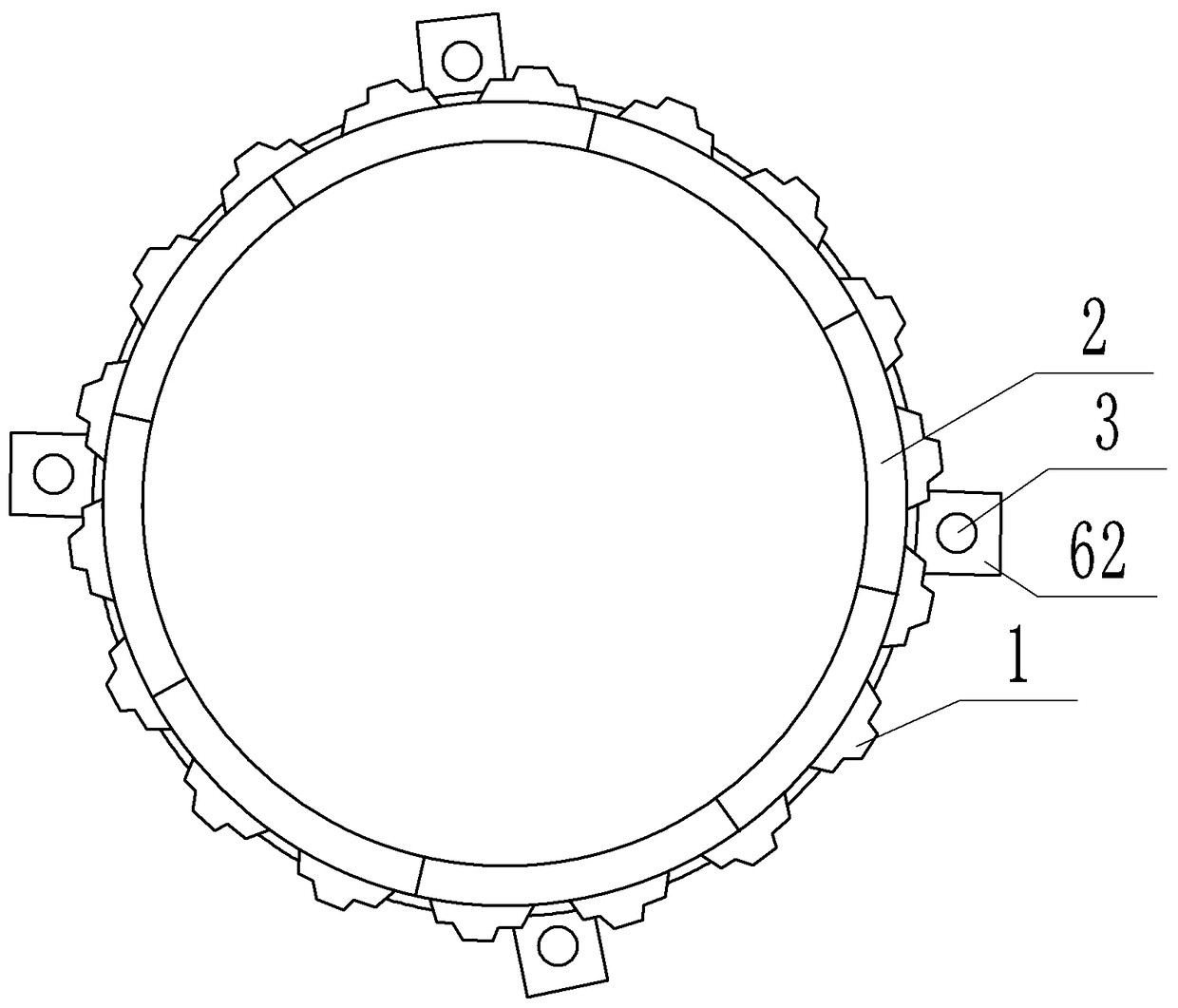

[0026] Such as figure 1 , figure 2 As shown, a steel casing device that is convenient for recycling includes a plurality of fixed rods 3, a supporting steel casing 4 and at least two steel casing bodies 6, and the supporting steel casing 4 and the steel casing body 6 are composed of A plurality of corrugated webs 1 are assembled end to end to form. The inner walls of the supporting steel casing 4 and the steel casing body 6 can be detachably connected with a fixed ring beam 2 with upper and lower layers, and the fixed ring beam 2 is composed of a plurality of curved beams spliced end to end. A plurality of fixing parts 42 (four in this embodiment) are welded on the outer wall of the supporting steel casing 4, and the fixing parts 42 are provided with threaded holes, and the lower part of the fixing rod 3 is provided with threads matching the threaded holes; Also be fixed with 4 connection parts 62 on the outer wall of steel casing body 6, have through hole on the connecti...

Embodiment 2

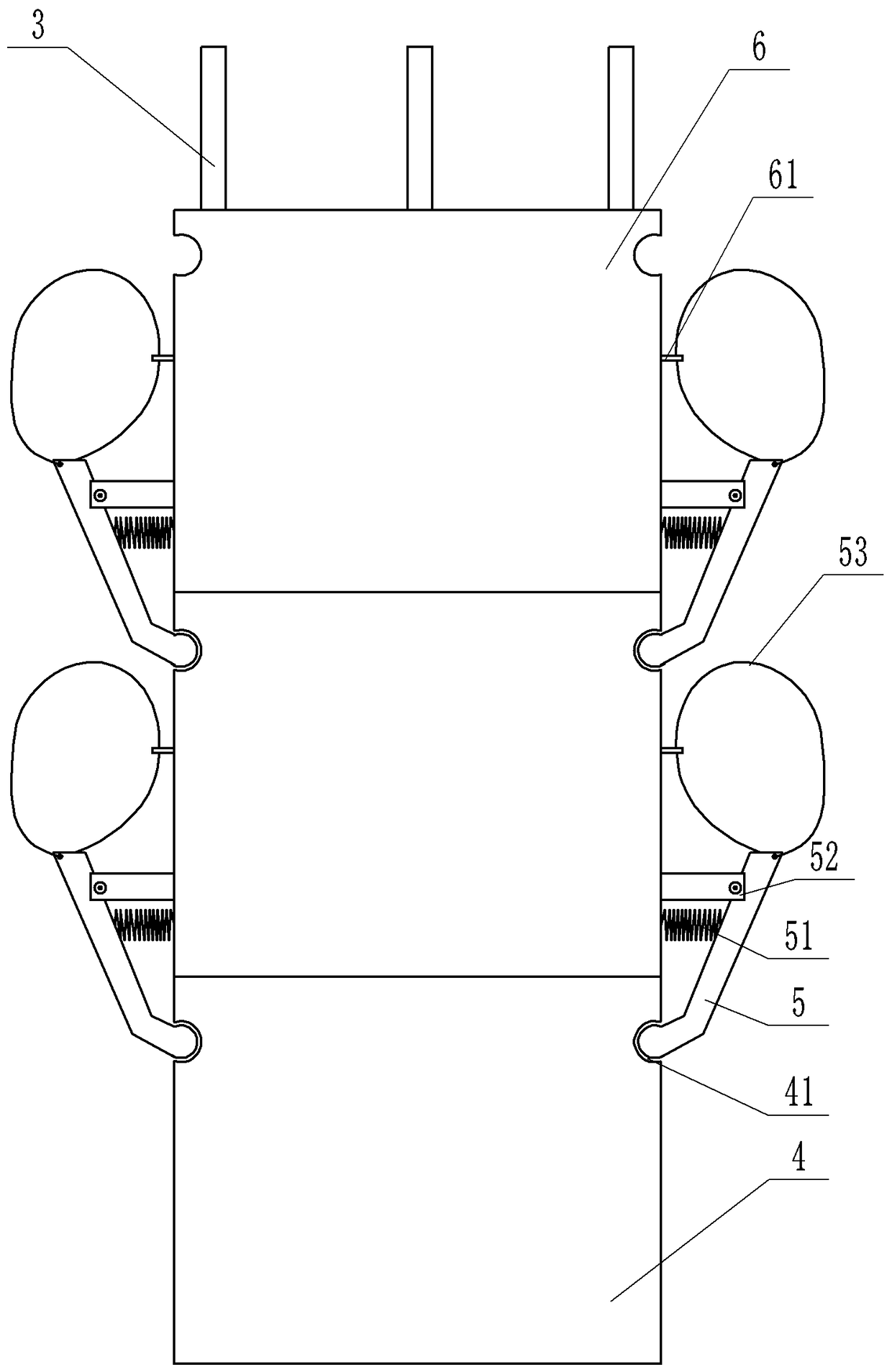

[0029] The difference between the second embodiment and the first embodiment is that the fixing part 42 of the second embodiment is welded on the inner wall of the supporting steel casing 4, and the connecting part 62 is welded on the inner wall of the steel casing body 6, as image 3 , Figure 4 shown. The steel casing sinks in the water, the fixed rod 3 passes through the fixed part 42 and the connecting part 62, and is located inside the steel casing; when the steel casing is in the water, it will receive huge pressure from the water, and the fixed rod 3 is arranged on the inner wall of the steel casing , can strengthen the structure of the steel casing and increase the compressive capacity of the steel casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com