Pipe pillar of multi-pipe injecting and washing technique of well controlling and inverse well-flushing integration

A technology of process pipe string and backwashing well, which is applied in the direction of flushing wellbore, wellbore/well components, and production fluid, etc., can solve the problem that the pipe string does not have well control protection ability, overhaul, water injection safety and marine environment protection awareness And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

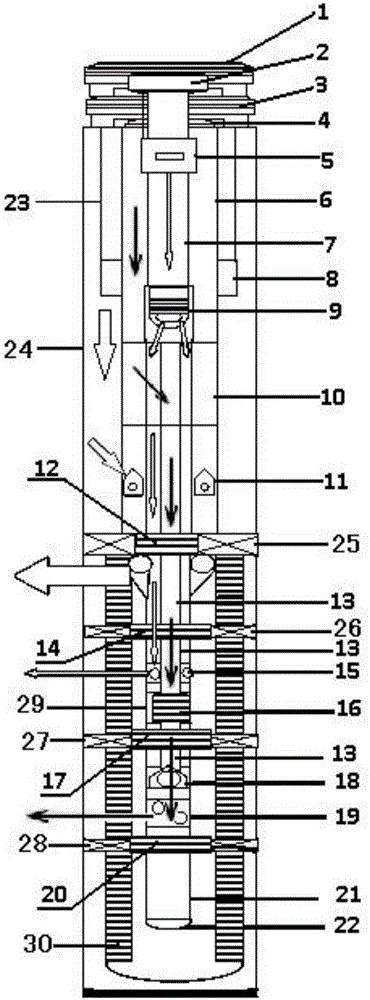

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, a well-controlled backwashing integrated multi-tubular injection and washing process string of the present invention includes a casing 24, and a top packer 25, a first One isolation packer 26, the second isolation packer 27 and the third isolation packer 28, the top packer 25, the first isolation packer 26, the second isolation packer 27 and the third isolation packer The packers 28 are connected to each other through the screen pipe 30, and divide the water injection well into a first water injection layer, a second water injection layer and a third water injection layer from top to bottom.

[0020] The top packer 25 is provided with a positioning insertion seal 12, and the upper part of the positioning insertion seal 12 is sequentially connected with an annular anti-reflux check valve 11, a bridge channel 10, a lifting device 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com