Fuel Vapor Gas Purification System

A technology of gas purification system and fuel vapor, which is applied in the direction of charging system, fuel air inlet, fuel injection device, etc., and can solve problems such as leakage of evaporated fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

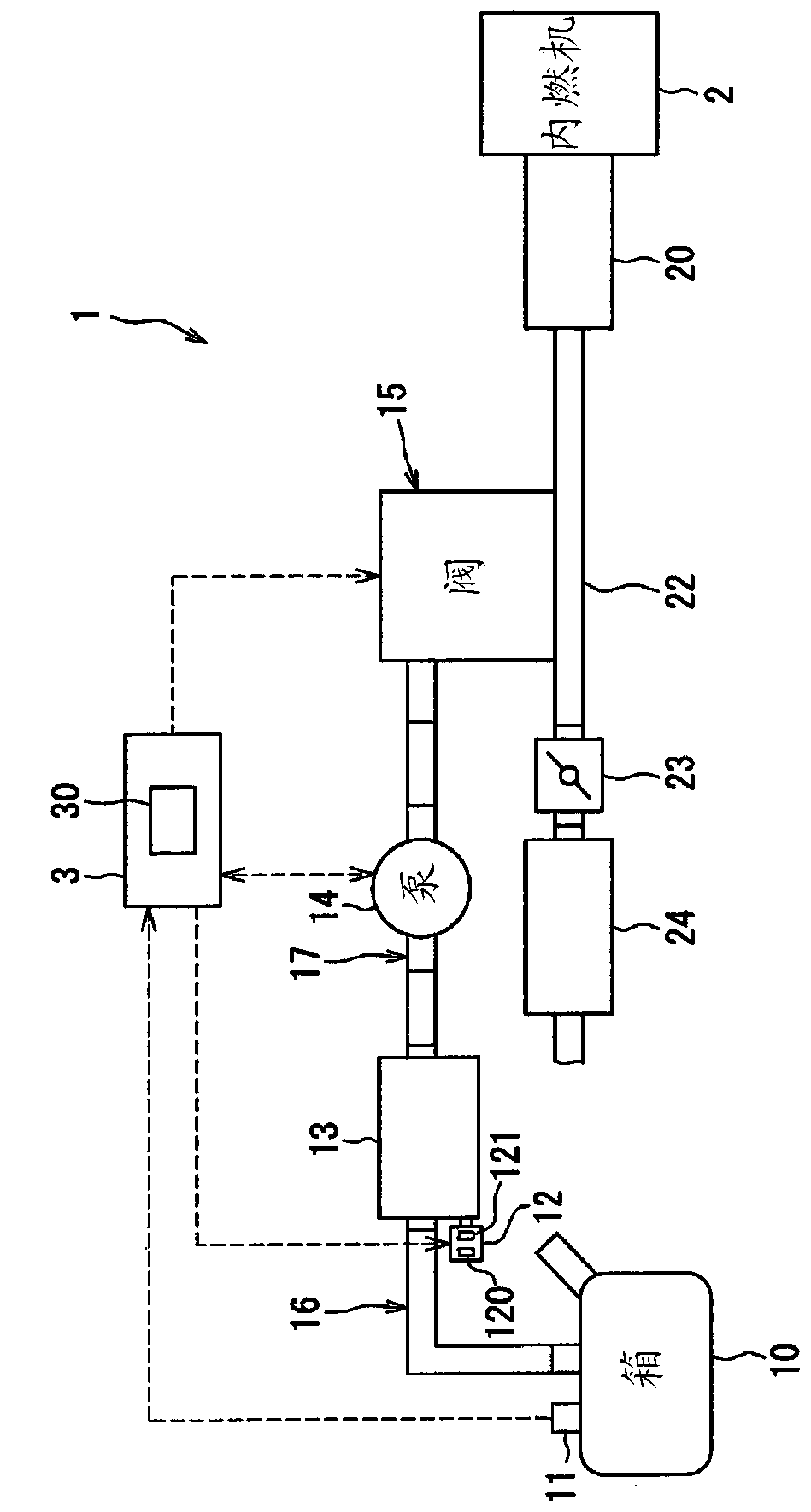

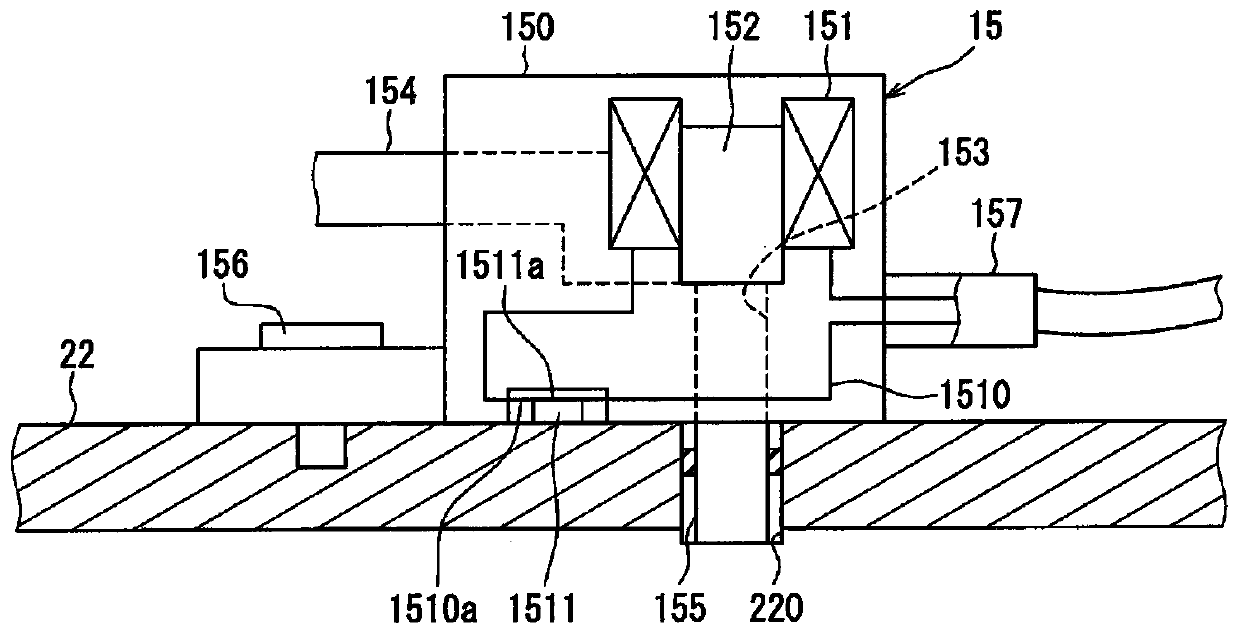

[0022] refer to Figure 1-Figure 5 , the fuel vapor gas purification system 1 according to the first embodiment will be described. The fuel vapor gas purification system 1 supplies hydrocarbon (HC) gas and the like contained in the fuel adsorbed to the canister 13 into an intake passage of the internal combustion engine. The fuel vapor gas purification system 1 prevents fuel vapor gas (hereinafter may be referred to as evaporated fuel) generated in the fuel tank 10 from being released into the atmosphere. The fuel vapor gas purification system 1 may be referred to as "system 1". Such as figure 1 As shown, the system 1 includes an intake system including an intake passage of an internal combustion engine 2 and an evaporated fuel purification system that supplies evaporated fuel to the intake system of the internal combustion engine 2 .

[0023] The evaporated fuel introduced into the intake passage of the internal combustion engine 2 is mixed with the combustion fuel supplie...

no. 2 example

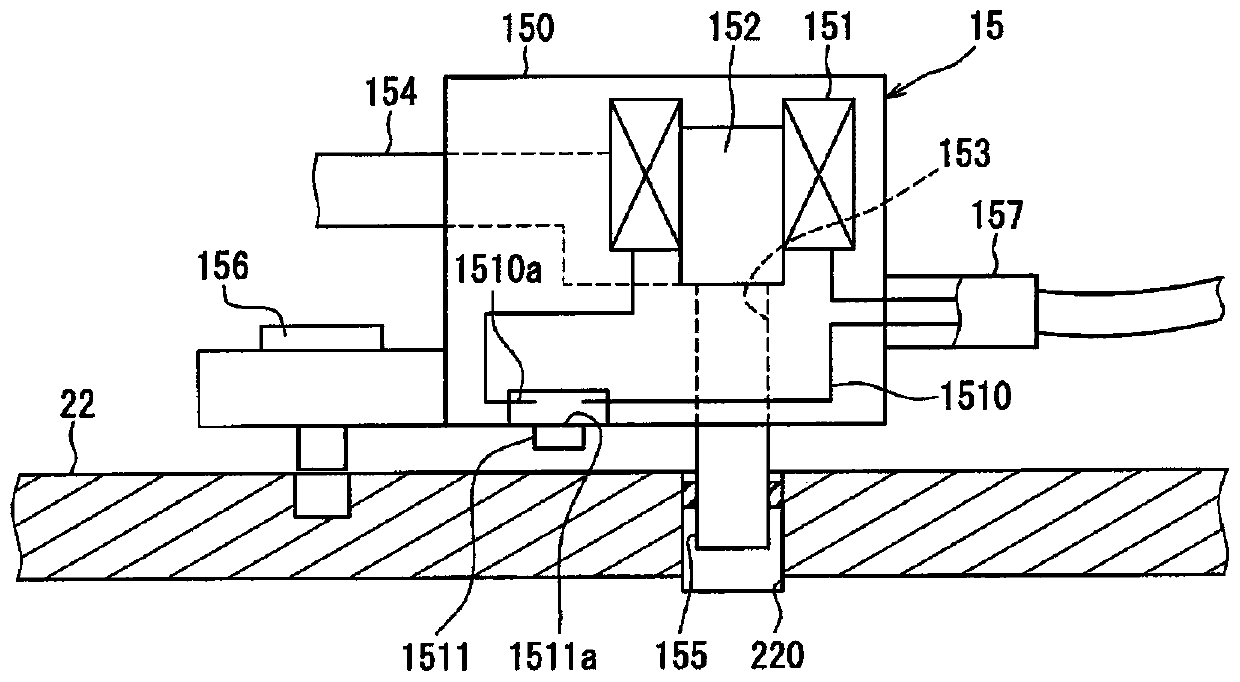

[0060] will refer to Figure 6 and Figure 7 , the fuel vapor gas purification system according to the second embodiment will be described. In each drawing, components similar to those of the first embodiment are given the same reference numerals, and have similar functions and effects. Configurations, functions and effects not specifically described in the second embodiment are similar to those of the first embodiment. Hereinafter, in the second embodiment, only points different from the above-described embodiments will be described. In the second embodiment, components including configurations similar to those of the above-described embodiment have functions and effects similar to those described in the above-described embodiment.

[0061] Such as Figure 6 As shown, the purge valve 115 as an example of the valve device differs from the first embodiment in the configuration of the switch portion 221 . The contact terminal 1510a of the circuit 1510 is connected to a swit...

no. 3 example

[0065] will refer to Figure 8 , the abnormality detection control of the fuel vapor gas purification system according to the third embodiment will be described. Configurations, functions, and effects not specifically described in the third embodiment are similar to those of the above-described embodiments. Hereinafter, in the third embodiment, only points different from the above-described embodiments will be described. In the third embodiment, components including configurations similar to those of the above-described embodiments have functions and effects similar to those described in the above-described embodiments.

[0066] The abnormality detection control described in the third embodiment is different from that of the first embodiment in that the valve device is supplied with current from the beginning, and the pump is operated during the leak check.

[0067] when Figure 8 At the beginning of the flow chart of , the controller 3 controls the purge valve 15 to be in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com