High-precision hydraulic telescopic rod

A hydraulic telescopic rod, high-precision technology, applied in the hydraulic field, can solve the problems of not meeting the precision requirements, and achieve the effects of direct measurement, improved control precision, and accurate movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

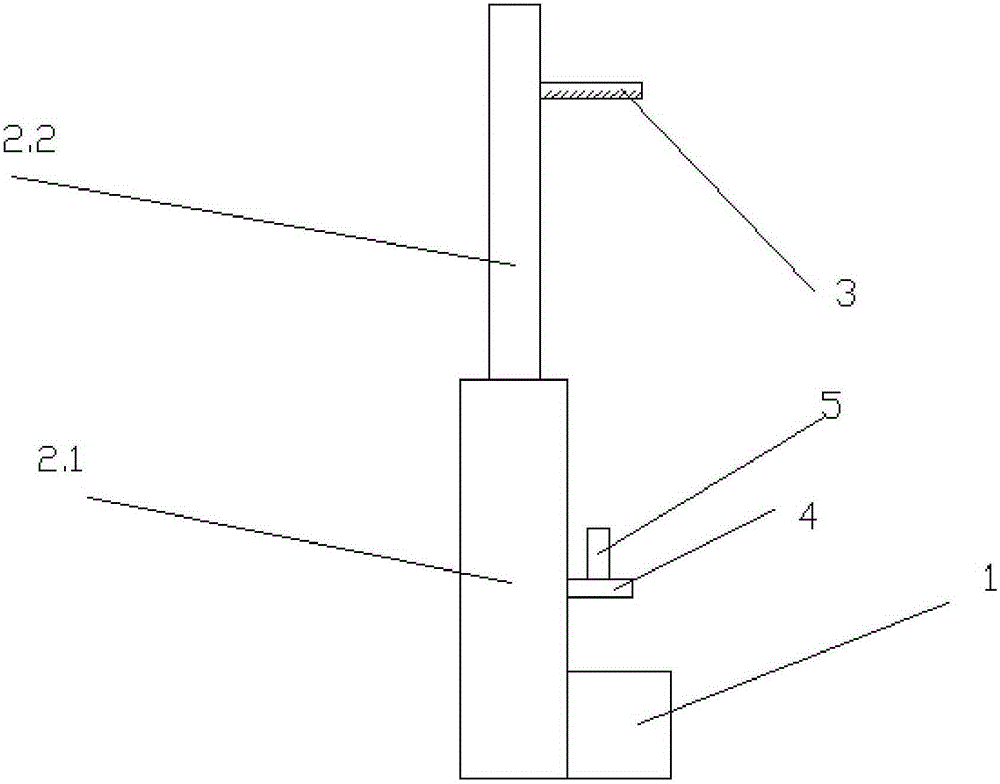

[0011] A high-precision hydraulic telescopic rod, including an oil cylinder, a hydraulic control valve group, and an oil pump motor 1. The oil cylinder includes a cylinder barrel 2.1 and a piston rod 2.2 located in the cylinder barrel. A sensor is provided on the outer wall of the end of the cylinder barrel far away from the piston rod. Support 4, the sensor bracket is provided with a laser ranging sensor 5, the piston rod is provided with a reflector 3 on the outer wall of one end away from the cylinder, and the side opposite to the laser ranging sensor is provided with a launch surface; The hydraulic telescopic rod is also provided with a controller and an alarm device, and the alarm device, the oil pump motor and the laser ranging sensor are connected to the controller; When the stroke difference of the piston rod measured by the distance measuring sensor is greater than the set threshold value, the alarm device is activated to alarm. The controller is a PLC controller. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com