Low-temperature fire extinguisher valve structure

A technology for fire extinguishers and valves, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve problems such as leakage of fire extinguisher valves, and achieve the effect of good sealing reliability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

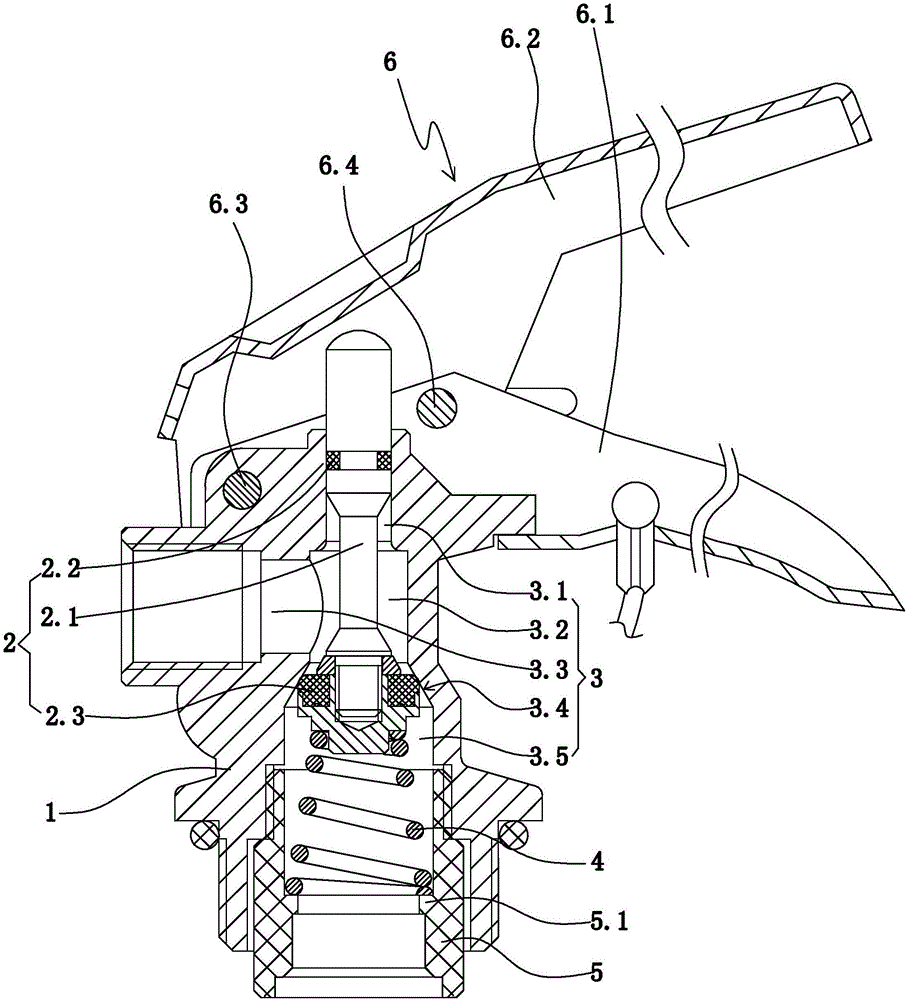

[0031] Example 1: Such as figure 1 As shown, a low-temperature fire extinguisher valve structure includes a valve body 1; a valve body flow passage 3 arranged in the valve body; a valve core 2 used to control the on-off of the valve body flow passage; a riser sleeve 5; The first return spring 4 and the fire extinguisher handle 6.

[0032] The valve body flow passage includes a main flow passage penetrating the upper and lower ends of the valve body, and a valve body outlet 3.3 which is arranged on the side surface of the valve body and communicates with the main flow passage. The lower port of the main flow channel constitutes the inlet of the valve body. The main flow path includes an upper valve hole 3.1, a middle valve hole 3.2 located below the upper valve hole, a tapered valve hole 3.4 whose inner diameter gradually decreases from bottom to top, and a lower valve hole 3.5 located below the middle valve hole. The inner diameter of the middle valve hole is larger than the inn...

Embodiment 2

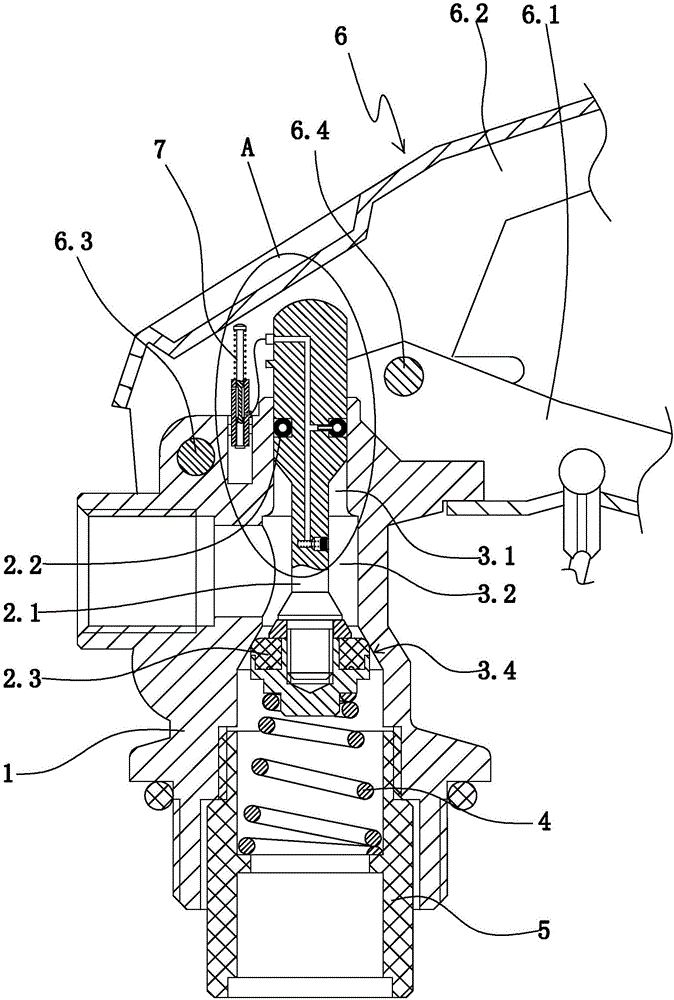

[0044] Embodiment 2: The rest of the structure of this embodiment refers to Embodiment 1, and the difference lies in:

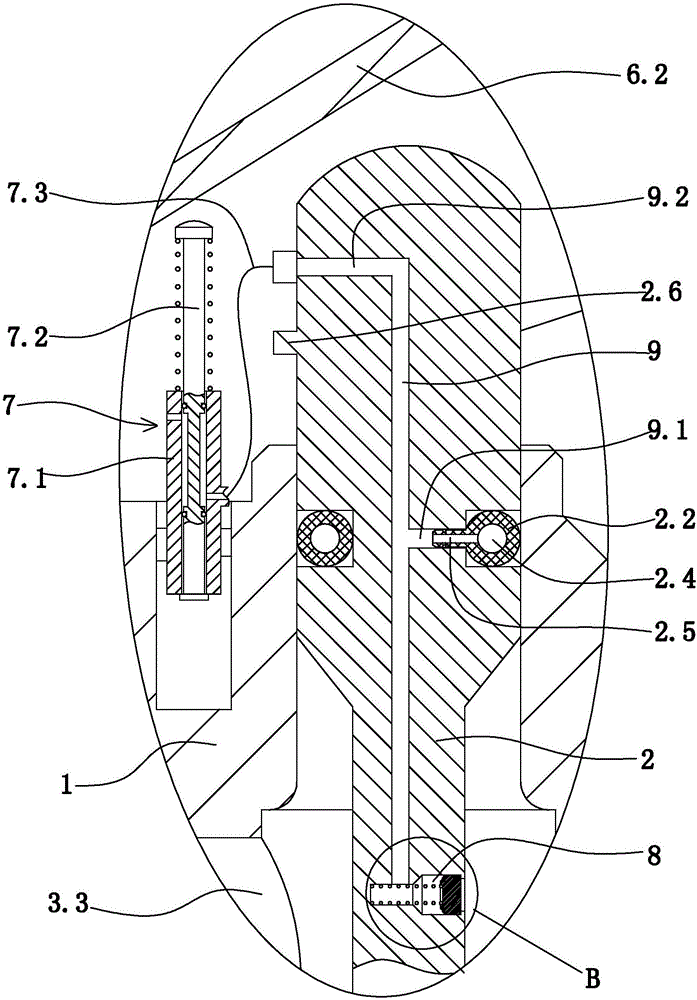

[0045] Such as figure 2 , image 3 As shown, a low-temperature fire extinguisher valve structure further includes an adaptive charging and discharging sealing structure. An installation groove for the sealing ring on the valve stem is provided on the outer surface of the valve stem. The upper sealing ring of the valve stem is arranged in the mounting groove of the upper sealing ring of the valve stem. An annular gas filled cavity 2.4 is provided in the sealing ring on the valve stem. The outer surface of the sealing ring on the valve stem is also provided with an inflatable cannula 2.5 communicating with the annular inflatable cavity.

[0046] The self-adaptive charging and discharging sealing structure includes an self-adaptive on-off mechanism 7, a pressure-type inflatable structure 8, and a main channel 9 in the valve stem.

[0047] Such as image 3 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com