Drying oven of soybean products

A bean product and oven technology, which is applied in the field of bean product oven, can solve the problems of uneven drying and wetness of materials, high energy consumption, and poor drying effect, and achieve the effect of excellent structure, good uniformity, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

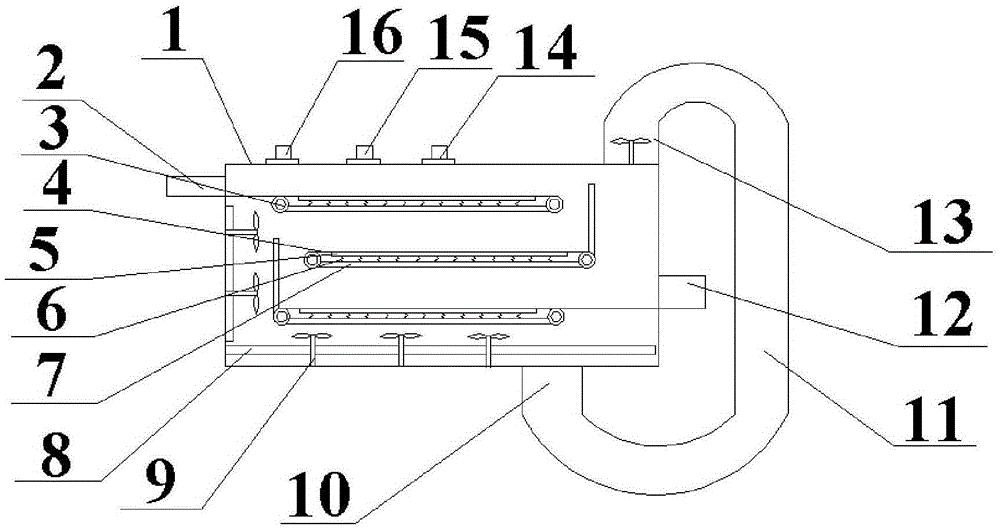

[0017] In the first embodiment, if figure 1 Provided is an oven for bean products, comprising a heating device, a conveying device, and an air supply device inside a box body 1, and a material inlet 2, a material outlet 13, an air inlet 10, an air outlet 14, and a heating regulator outside the box body 1. Switch 15, vibration adjustment switch 16, transmission adjustment switch 17 and air duct 12, described heating device includes the electric heating tube 8 that is arranged on the vertical side inner wall of box body 1 and the horizontal bottom wall surface, and transmission device includes conveyor belt 4, reel 3 and The connecting shaft 7 is provided with a vibrating plate 5 on the lower surface of the conveyor belt 4, and the vibrating plate 5 is connected to the connecting shaft 7 through a spring 6. The air supply device includes fans respectively arranged on the vertical electric heating tube 8, the horizontal electric heating tube 8 and the air outlet 14. 9. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com