Multi-blade saw cutting equipment and control method thereof

A technology for cutting equipment and multi-blade saws, which is applied in the direction of sawing equipment, circular saws, manufacturing tools, etc., can solve the problems of motor stall, increase the production cost of enterprises, reduce the production efficiency of enterprises, etc., and achieve excellent structure and strong practicability , ingeniously designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

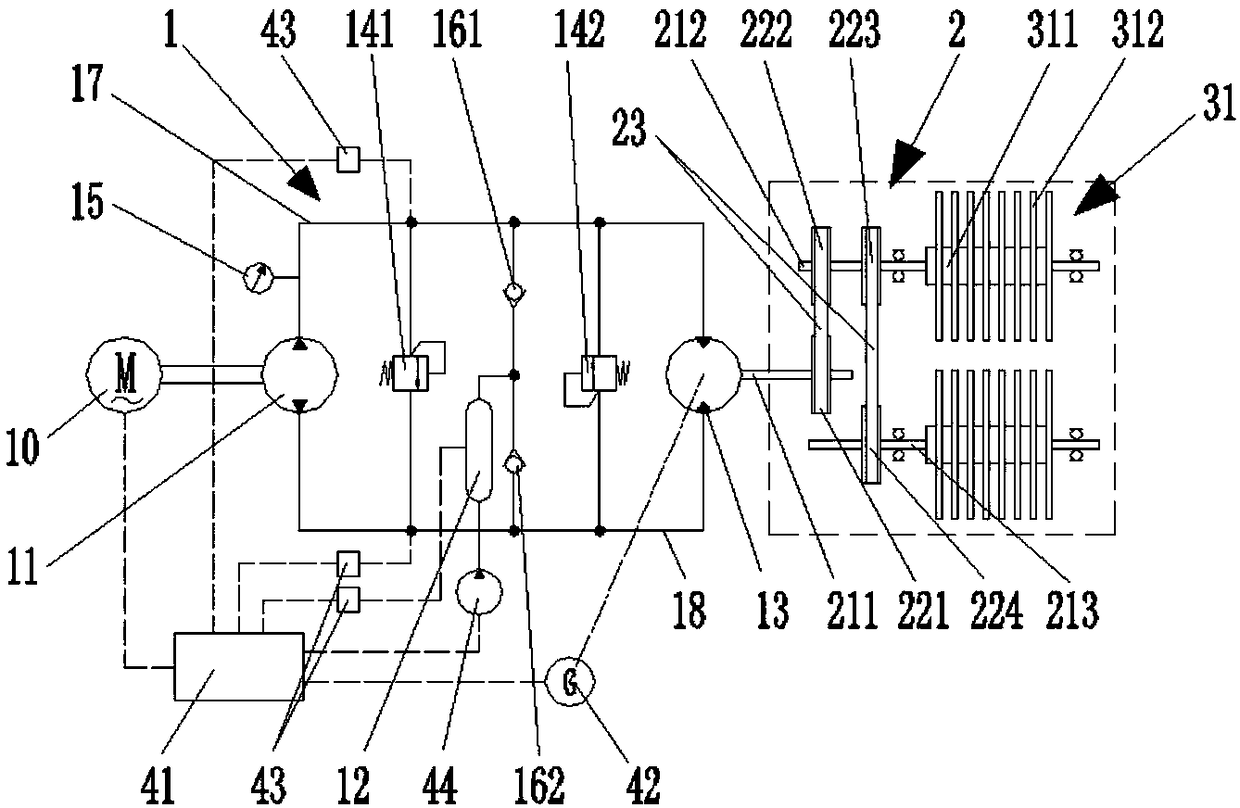

[0023] see figure 1 , a multi-blade saw cutting equipment, including a hydraulic system 1, a transmission mechanism 2 and an actuator, the hydraulic system 1 provides mechanical kinetic energy to the actuator through the transmission mechanism 2, and it is characterized in that: the hydraulic system 1 includes a main motor 10 , two-way quantitative pump 11, oil supply tank 12, two-way hydraulic motor 13, first overflow valve 141, second overflow valve 142, first one-way valve 161 and second one-way valve 162; the two-way quantitative pump 11 The pump oil is driven by the main motor 10, and the two ends of the two-way quantitative pump 11 are respectively connected to the two ends of the two-way hydraulic motor 13 through the first oil circuit 17 and the second oil circuit 18, and drive the hydraulic motor 13 to rotate; the first oil The oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com