Low-ignition-voltage and high-power-output miniature detonator

A low-ignition, miniature technology, applied in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of electric detonator safety current reduction, small size, high output power, etc., and achieve the effect of comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

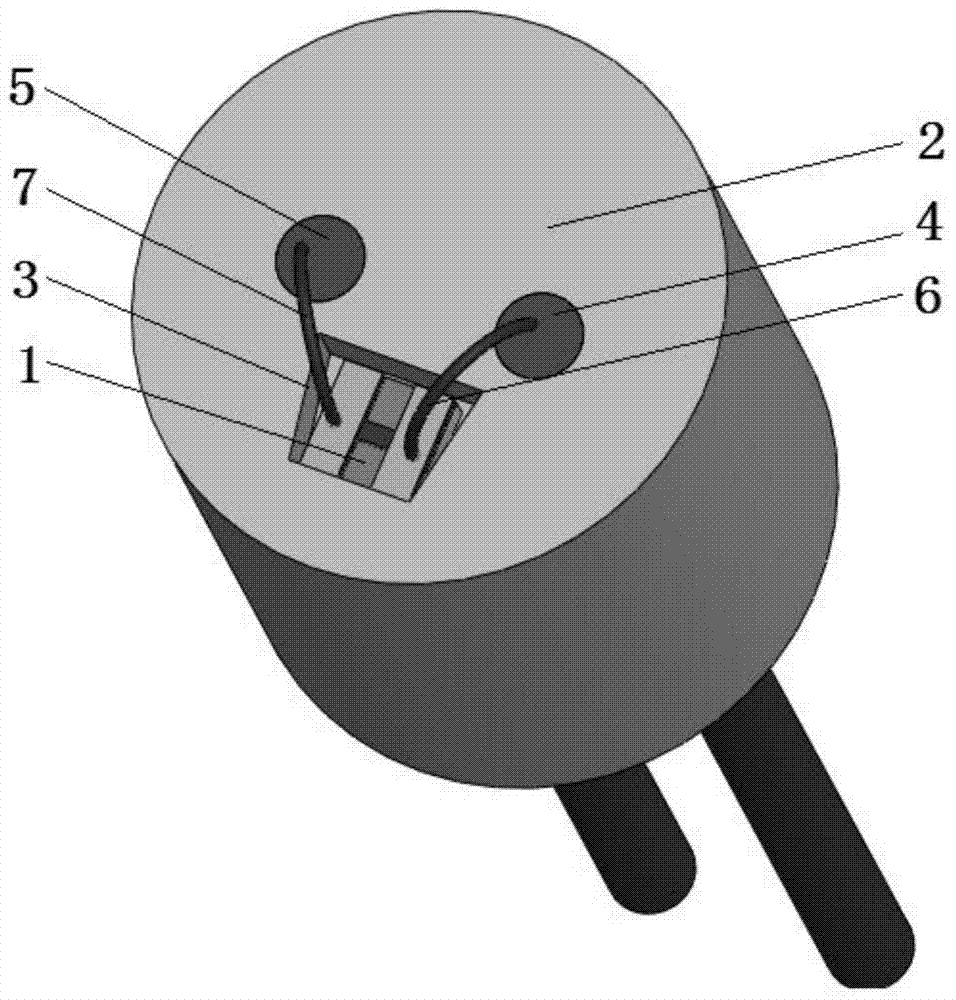

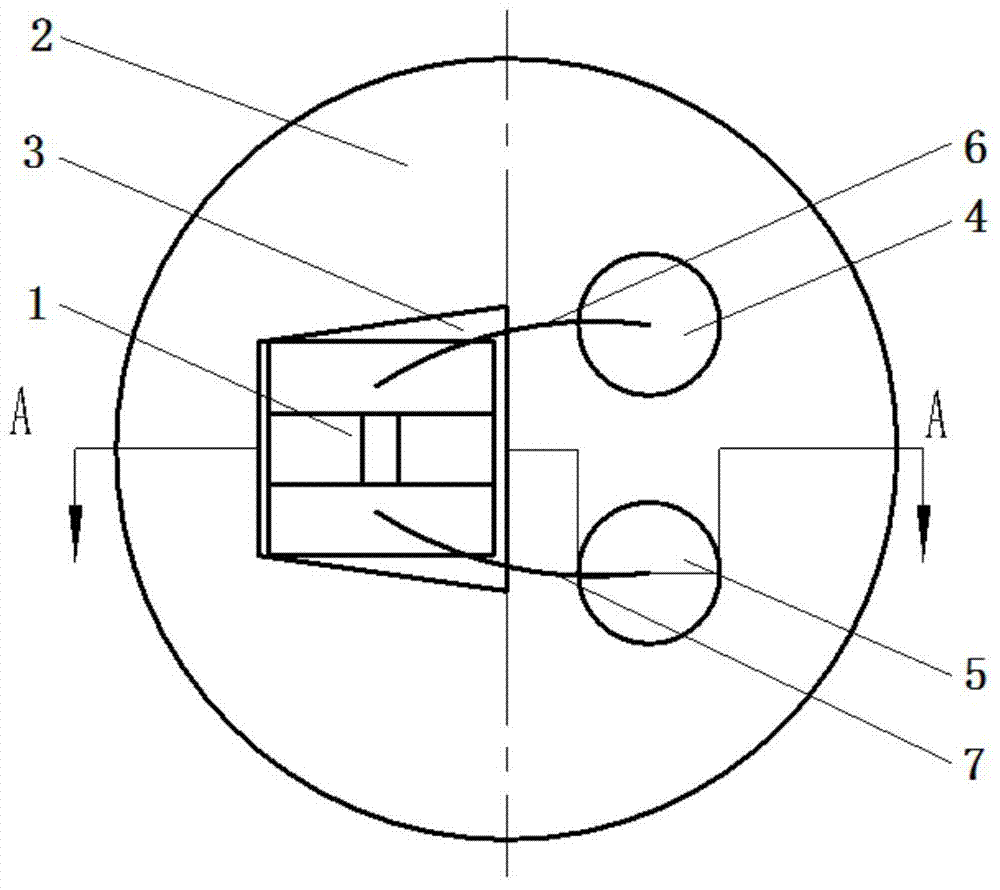

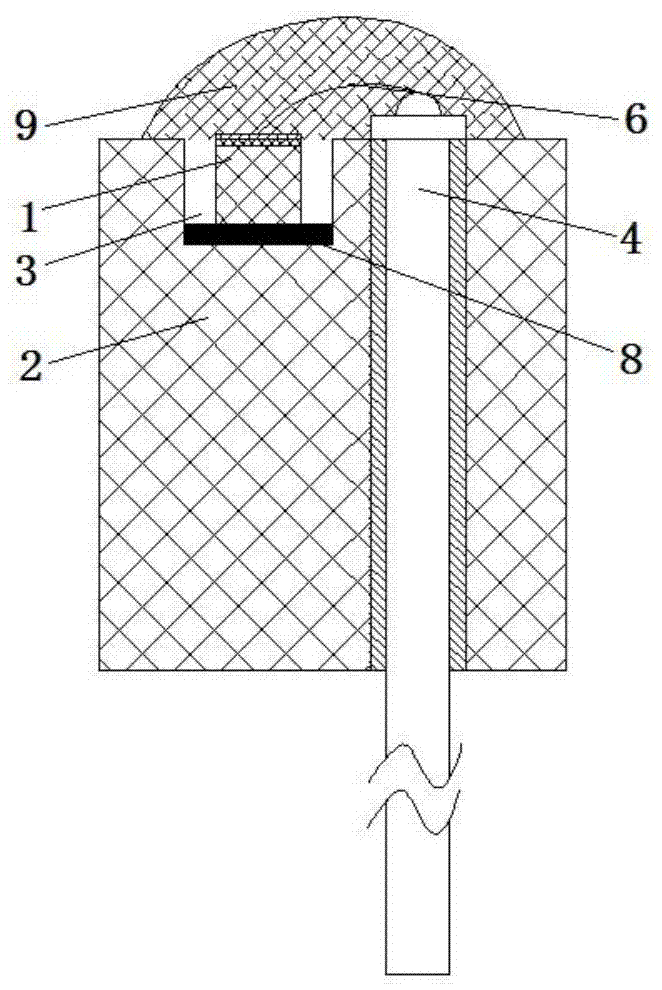

[0021] combine Figure 1-3 The low ignition voltage semiconductor bridge miniature ignition assembly includes three parts: semiconductor bridge transducer chip (1), asymmetric miniature ceramic electrode plug (2) and electrothermal sensitive ignition powder (9). Fix the rectangular semiconductor bridge transducer chip (1) in the trapezoidal groove (3) of the asymmetrical ceramic electrode plug (2) with an adhesive (8), adopt ultrasonic welding, and use bonding wires (6, 7) Connect the two metal pads on the semiconductor bridge transducer chip (1) to the two-leg electrodes (4, 5) of the ceramic electrode plug (2) respectively, so that the two leg electrodes of the electrode plug ( 4, 5) and the two metal pads of the semiconductor bridge transducer element to form a circuit path, and the semiconductor bridge transducer element is filled with electrothermal sensitive pyrotechnic powder (9) refine the neutral trinitroresorcinol lead to form an ignition component .

[0022] Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com