Method for preparing super-thick Ti-Al-C ternary coating using two-step method PVD technology

A ti-al-c, coating technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the inconvenience of long-term use and other problems, to achieve dense and smooth coating, good high temperature oxidation resistance , excellent binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

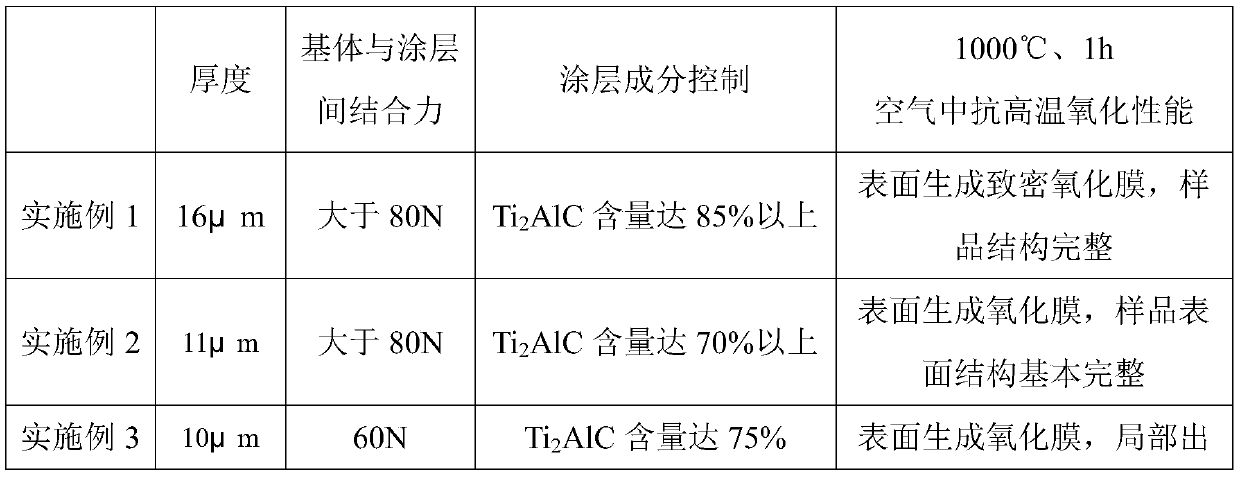

Embodiment 1

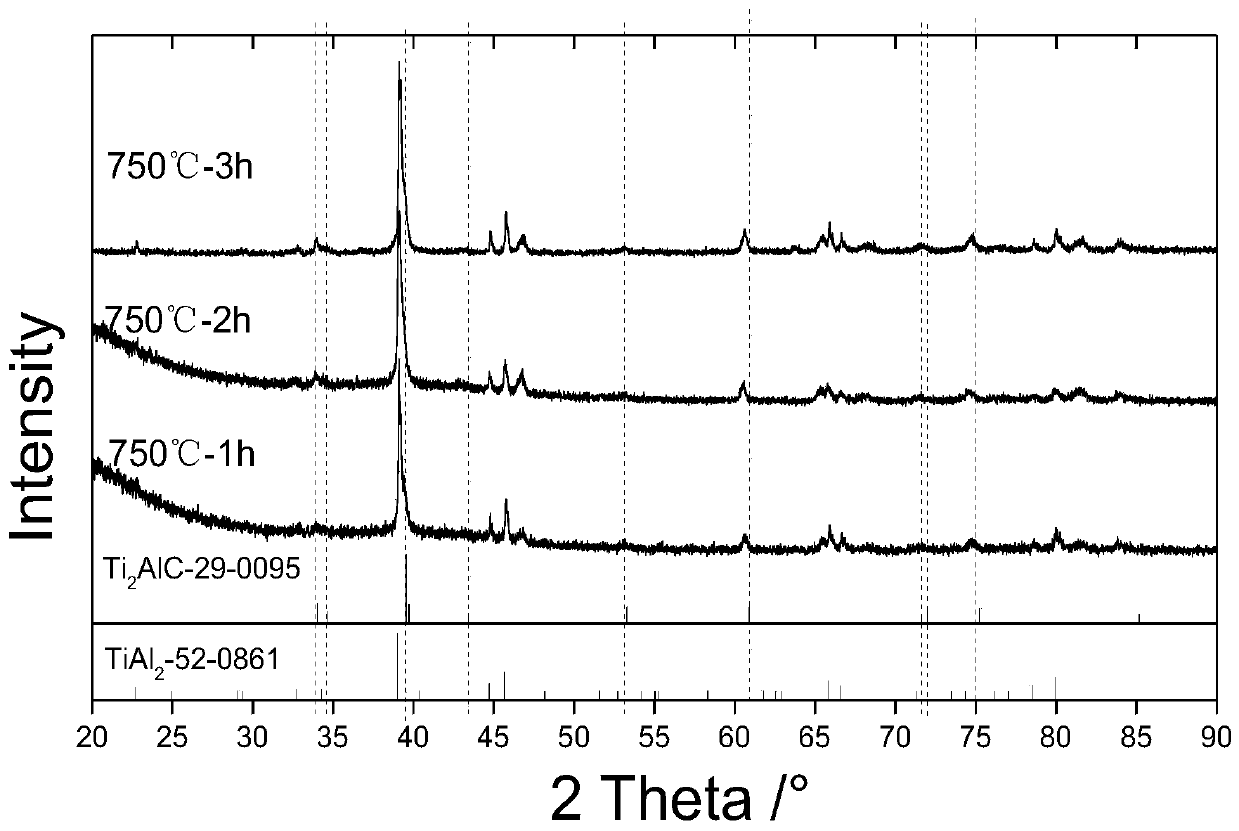

[0034] Such as figure 1 Shown, a kind of two-step method PVD technique of the present invention prepares the method for ultra-thick Ti-Al-C ternary coating, comprises the following steps:

[0035] Pre-preparation of Ti-Al-C ternary coating

[0036] (1) Pretreatment: Ultrasonic surface cleaning is performed on the zirconium substrate with acetone and deionized water respectively. After drying in a vacuum drying chamber, the sample is placed on the three-dimensional turret in the vacuum chamber, and the distance between the target and the base is kept at 200mm. Close it A high vacuum is drawn behind the furnace door, and the vacuum degree reaches 3.5×10 -3 After that, start to heat slowly;

[0037] (2) Ion cleaning: After reaching the coating temperature of 350°C, fill in Ar gas, apply high bias voltage, and perform glow sputtering cleaning on the substrate sample, or use an electron gun to heat, clean and etch the substrate sample to further clean the surface of the substrate...

Embodiment 2

[0045] Step 1: Pre-preparation of Ti-Al-C ternary coating

[0046] (1) Pretreatment: Ultrasonic surface cleaning is performed on the zirconium substrate with acetone and deionized water respectively. After drying in a vacuum drying chamber, the sample is placed on the three-dimensional turret in the vacuum chamber, and the distance between the target and the base is kept at 200mm. Close it A high vacuum is drawn behind the furnace door, and the vacuum degree reaches 3.5×10 -3 After that, start to heat slowly;

[0047] (3) Ion cleaning: After reaching the coating temperature of 350°C, fill in Ar gas, apply high bias voltage, and perform glow sputtering cleaning on the substrate sample, or use an electron gun to heat, clean and etch, and further clean the surface of the substrate sample . The Ar pressure is 2.0Pa, the bias voltage is -150V, the duty cycle is 70%, the buncher coil current is 11A, the electron gun power supply voltage is 45V, the current is 90A, and the cleaning...

Embodiment 3

[0055] (1) Pretreatment: Ultrasonic surface cleaning is performed on the zirconium substrate with acetone and deionized water respectively. After drying in a vacuum drying chamber, the sample is placed on the three-dimensional turret in the vacuum chamber, and the distance between the target and the base is kept at 200mm. Close it A high vacuum is drawn behind the furnace door, and the vacuum degree reaches 3.5×10 -3 After that, start to heat slowly;

[0056] (4) Ion cleaning: After reaching the coating temperature of 350°C, fill in Ar gas, apply high bias voltage, and perform glow sputtering cleaning on the substrate sample, or use an electron gun to heat, clean and etch, and further clean the surface of the substrate sample . The Ar pressure is 2.0Pa, the bias voltage is -150V, the duty cycle is 70%, the buncher coil current is 11A, the electron gun power supply voltage is 45V, the current is 90A, and the cleaning time is 30 minutes.

[0057] (3) Formation of the base coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com