A thin-film temperature sensor with resistance to piezoresistive effect and method for detecting temperature

A thin-film temperature and sensor technology, applied in thermometers, thermometers and instruments using electrical/magnetic components directly sensitive to heat, etc., can solve problems such as temperature measurement errors, surface resistance line stretching or compression, and changing resistance values, etc. Achieve the effect of eliminating measurement errors, improving response speed, and thin thermal conductive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

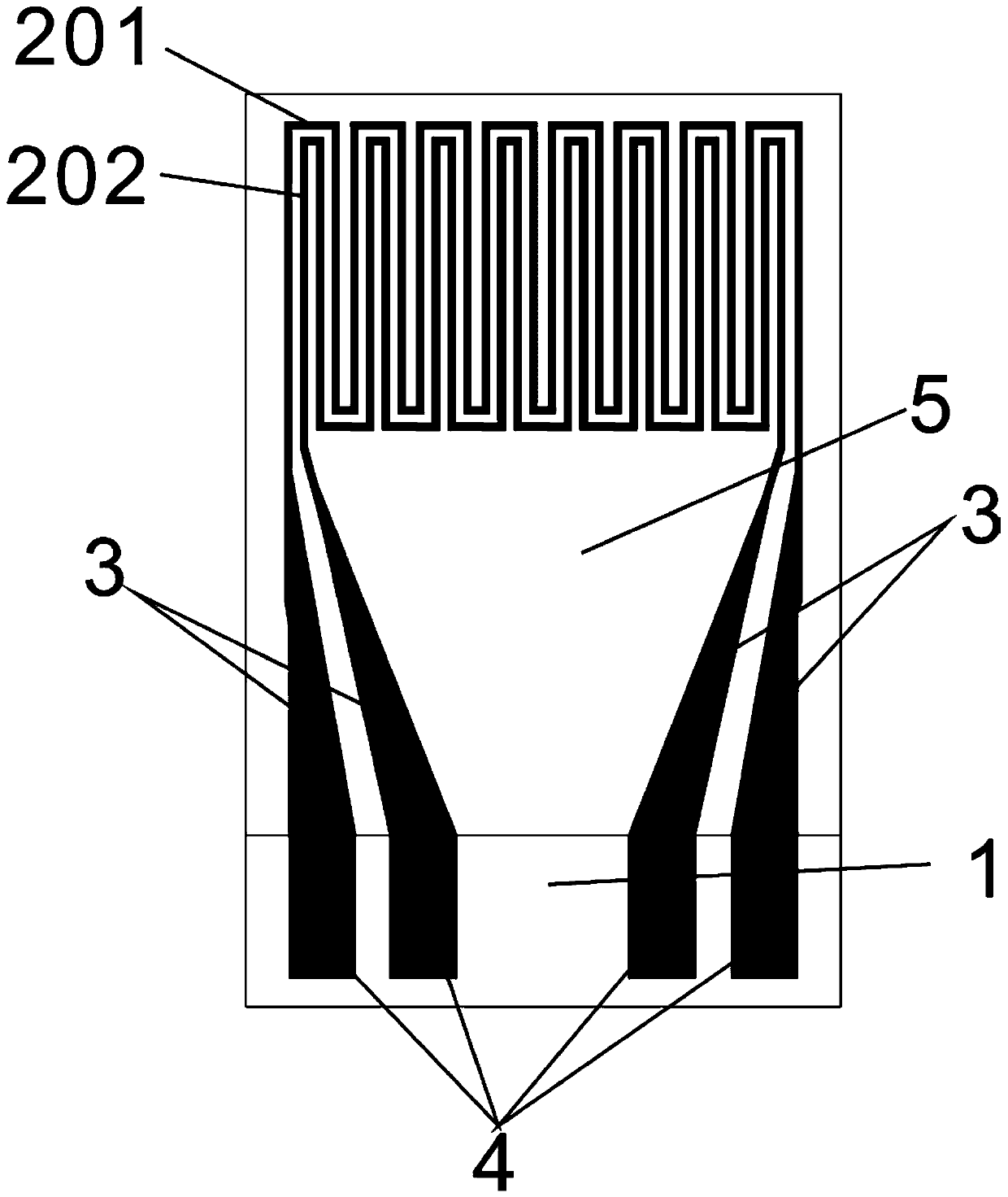

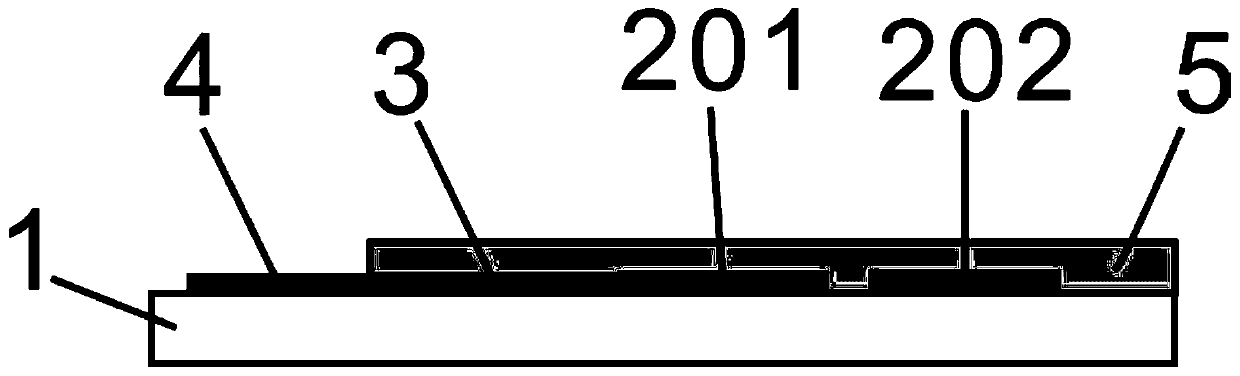

Image

Examples

Embodiment Construction

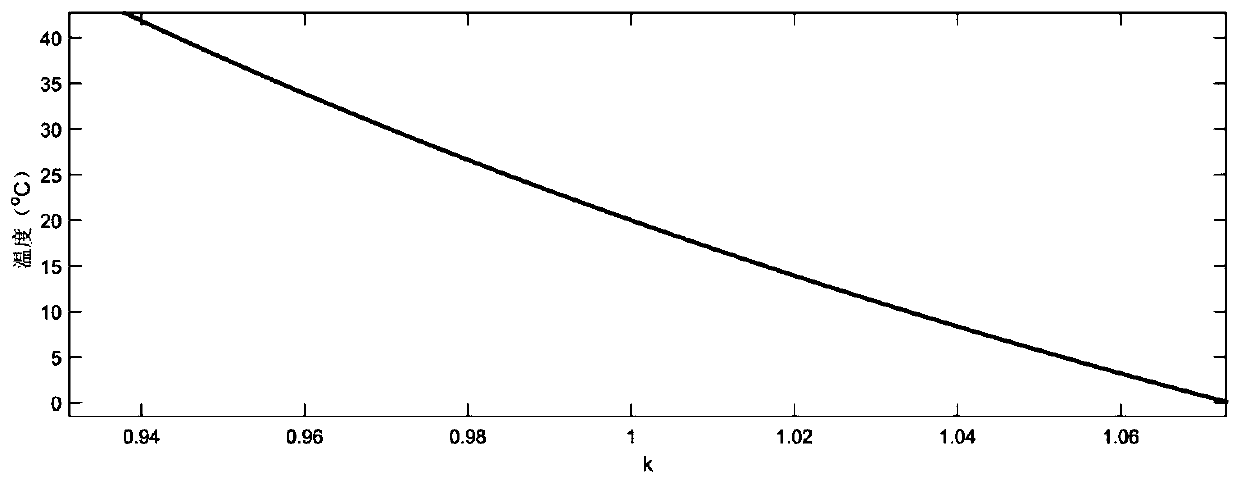

[0030] The basic principle of the present invention is as follows:

[0031] The relationship between the resistance value of metal or metal compound with temperature change can be approximated as a linear change, which is described by the following first-order polynomial:

[0032] R T =R T0 [1+α(T-T 0 )] [1]

[0033] where R T is the resistance value of the resistor at temperature T, R T0 for the resistance at temperature T 0 (generally 0°C, 20°C, 25°C) resistance value, and α is the temperature coefficient of resistance, which depends on the material of the resistance.

[0034] In order to improve the description accuracy, a 3rd degree polynomial can be used to describe the nonlinear relationship between temperature and resistance value:

[0035] R T =R T0 [1+α 1 (T-T 0 )+α 2 (T-T 0 ) 2 +α 3 (T-T 0 ) 3 ] [2]

[0036] where a 1 , α 2 , α 3 is the temperature coefficient in the form of coefficients of a 3rd degree polynomial, , depending on the material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com