Automobile six-degrees-of-freedom wheel center force test and vibration noise contribution rate calculation method

A technology of vibration noise and calculation method, which is applied in the field of vehicle engineering, can solve the problems of vehicle vibration noise energy contribution rate error, error, difficulty, etc., and achieve the effect of eliminating error and avoiding error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

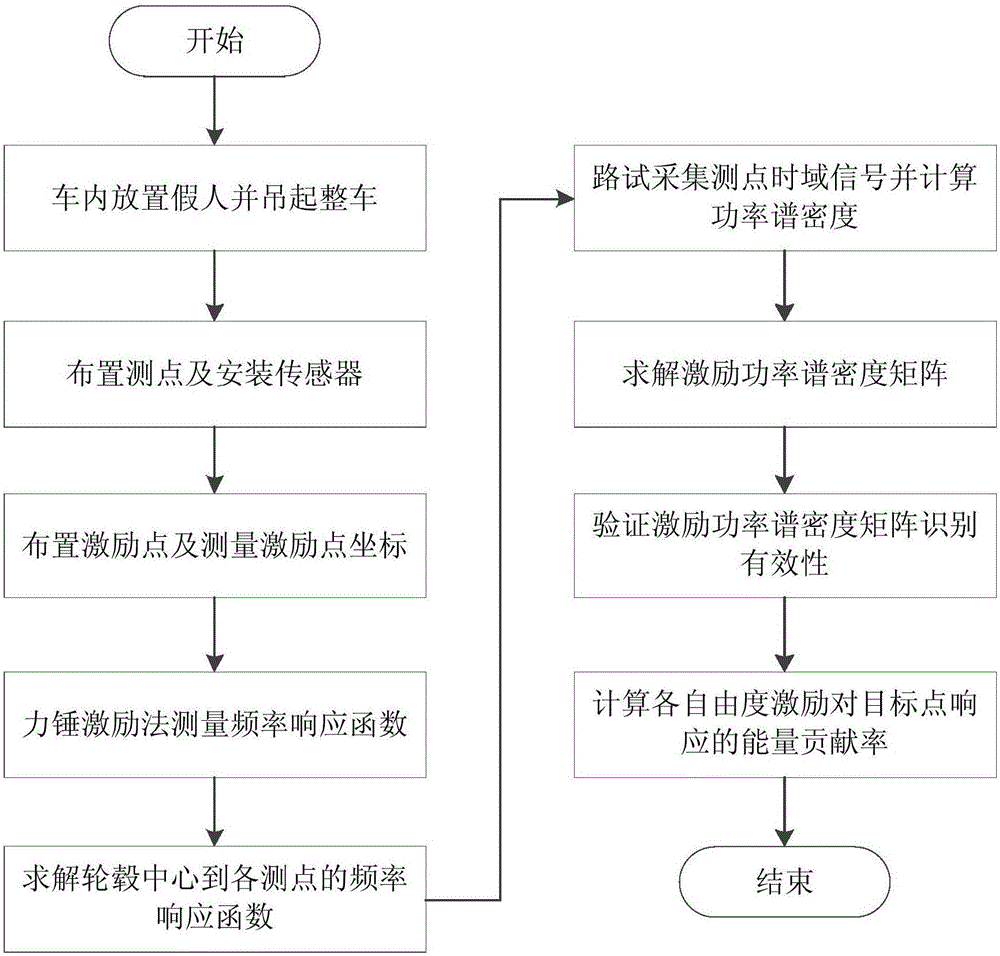

[0037] A six-degree-of-freedom wheel heart force test and calculation method for vibration and noise contribution rate, such as figure 1 As shown, the method includes: establishing a coordinate system, arranging measuring points and installing sensors, arranging excitation points and measuring the coordinates of excitation points, measuring frequency response functions, solving the frequency response function matrix from the center of the hub to the response point, and solving the matrix from the center of the hub to the response point. The frequency response function vector of the target point, road test, solving the excitation power spectral density matrix, verifying the effectiveness of the identification of the excitation power spectral density matrix, and calculating the energy contribution rate of each degree of freedom excitation to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com