Wafer rotational speed detection device in megasonic cleaning, cleaning system and working process of cleaning system

A technology of megasonic cleaning and speed detection, which is applied to the manufacture of devices using electric/magnetic methods, electrical components, semiconductor/solid-state devices, etc., can solve the problems that the speed of megasonic cleaning wafers cannot be detected, and improve work efficiency And quality, easy to use, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

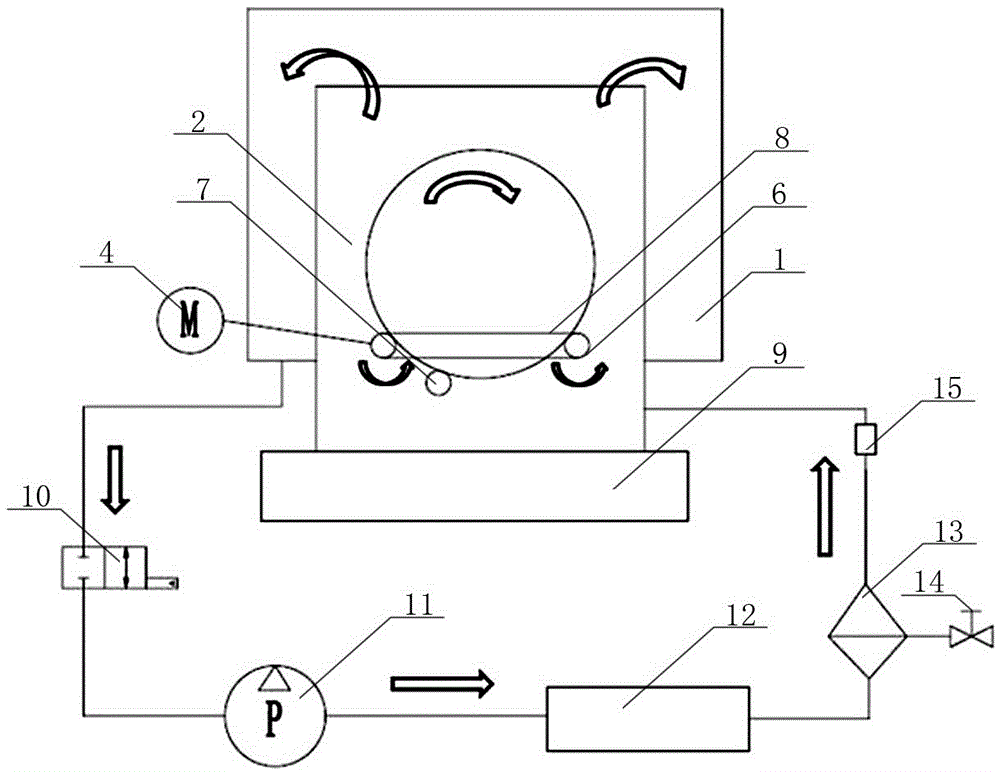

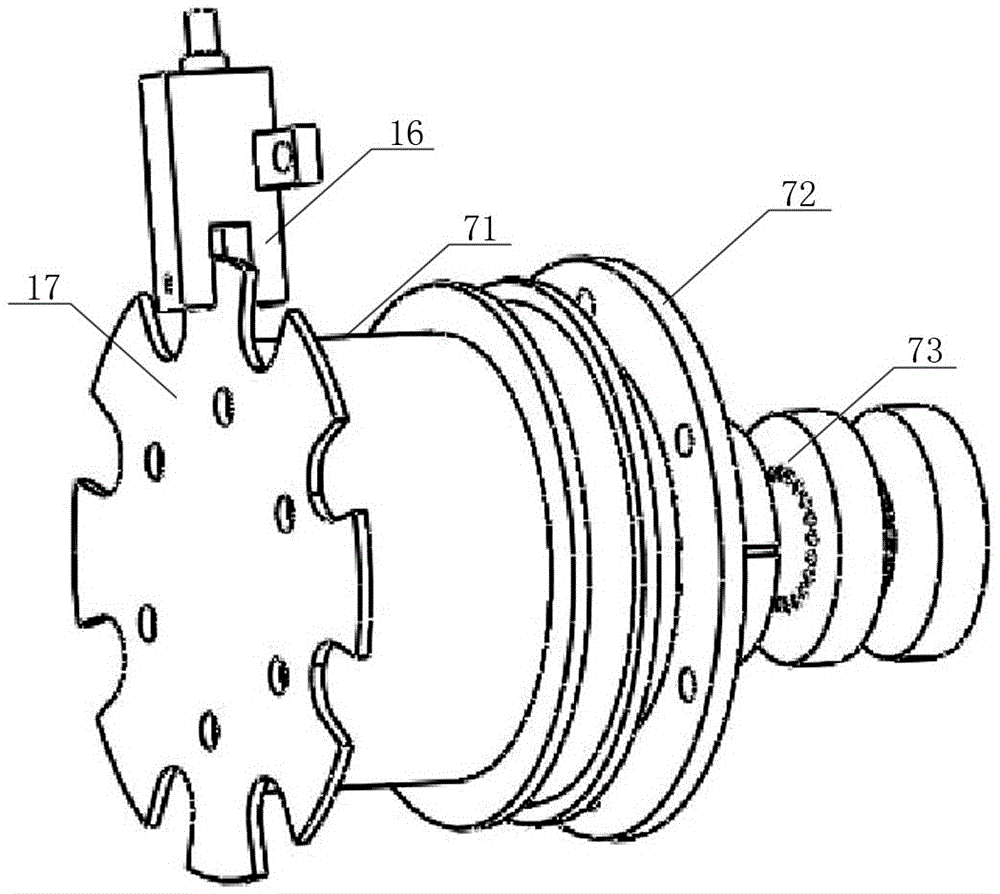

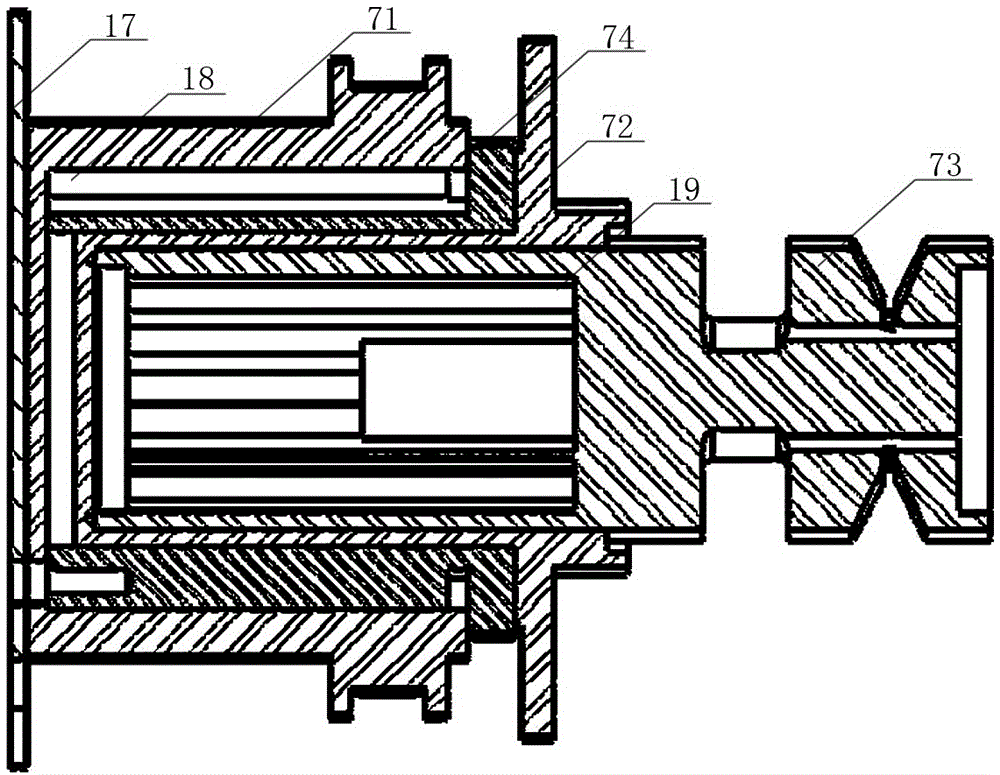

[0034] Examples see figure 1 As shown, the cleaning system includes a megasonic cleaning tank, a megasonic generating device 9 connected to the megasonic cleaning tank, and a first driving pulley 5, a second driving pulley 6 and a driven pulley arranged in the megasonic cleaning tank. Pulley assembly 7, see figure 2 , image 3 As shown, the driven pulley assembly 7 includes a wafer rotor 73, the wafer rotor 73 is cylindrical, and the center of one end is provided with a cylindrical keyway along the long direction to form a keyway section, and the other end is provided with a card slot along the circumferential direction. The slot connecting the wafer forms a slot section, and the key slot section and the slot section are connected by a transition section. The wafer rotor shield 72, wafer rotor shield 72, and wafer The rotor pulley cover 74 and the driven pulley 71, wherein the wafer rotor pulley cover 74 has a keyway; the driven pulley 71 is a metal part, the wafer rotor sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com