Fully-sealed SMIF system

A fully enclosed, sealing ring technology, used in electrical components, conveyor objects, transportation and packaging, etc., can solve problems such as bodily injury, treatment process influence, and cannot exceed a certain value, and achieve increased sealing and good sealing performance. , the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments describe the fully enclosed SMIF system of the present invention in detail in conjunction with the accompanying drawings.

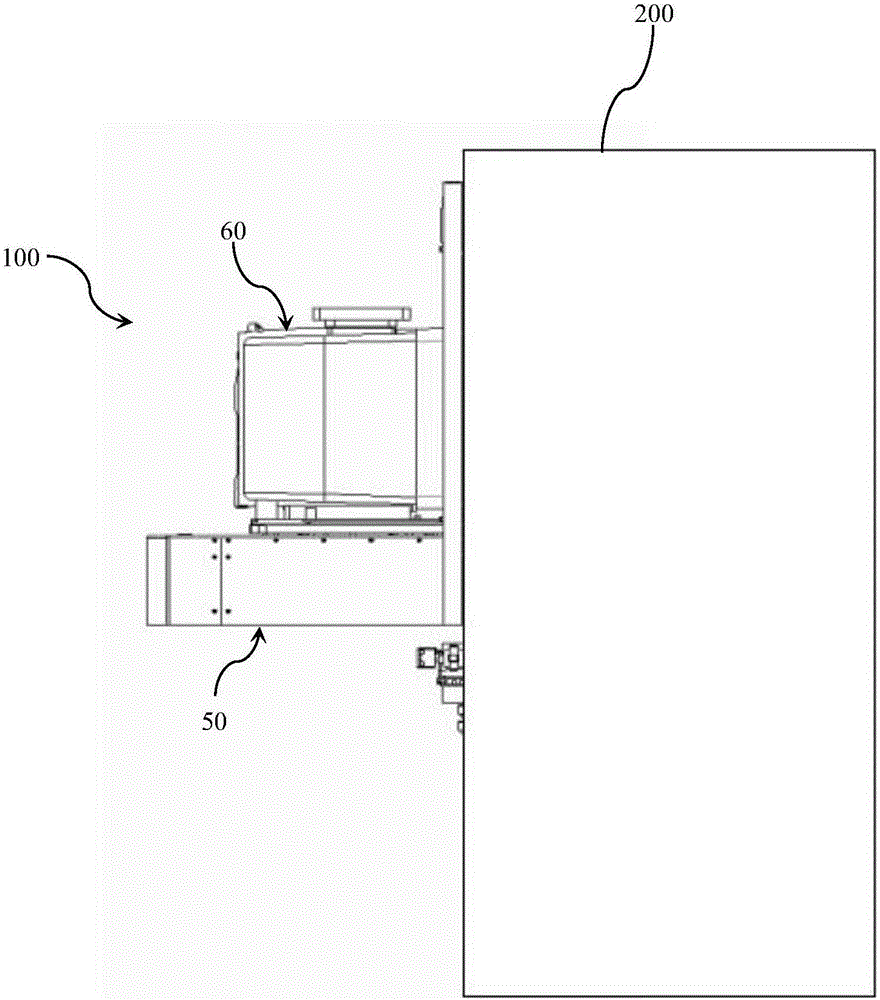

[0034] Such as figure 1 As shown, the fully enclosed SMIF system 100 is installed on one side of the box body 200 , and the fully enclosed SMIF system 100 is used to open the container 60 and deliver the products in the container 60 to the sealed box body 200 . In this embodiment, the product in the container 60 is a wafer. The box body 200 is provided with a processing device for processing semiconductors, and one side of the box body 200 is provided with an opening. The box body 200 is a sealed box with an opening, or a sealed room with an opening.

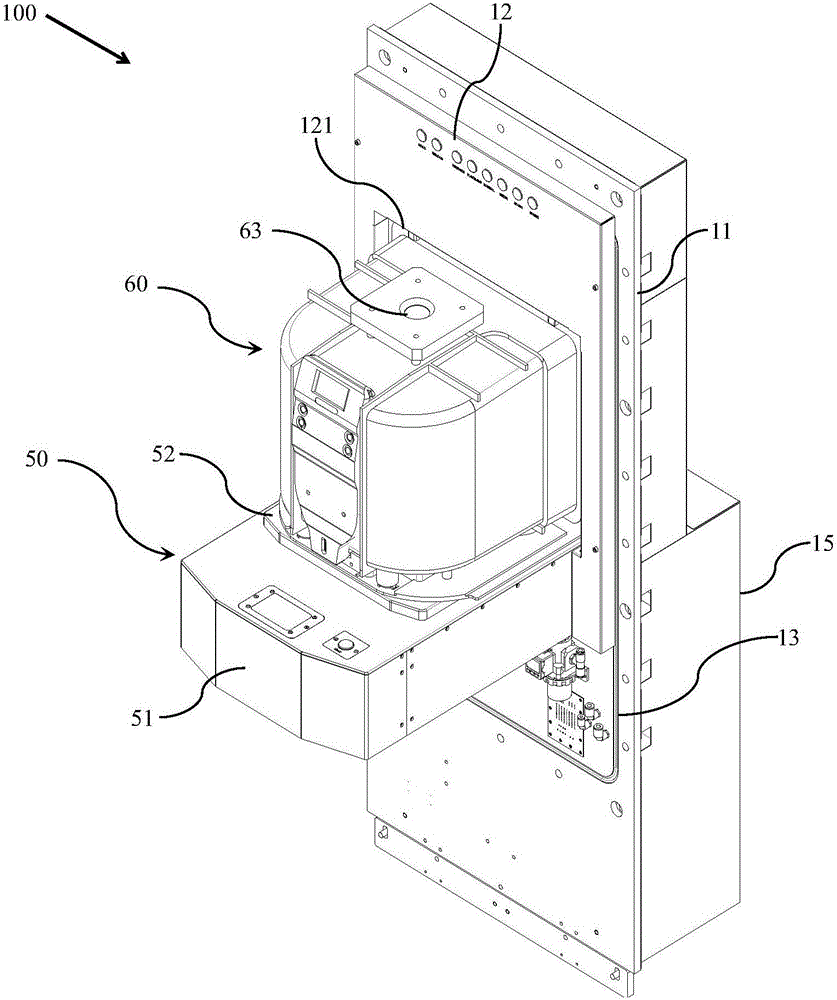

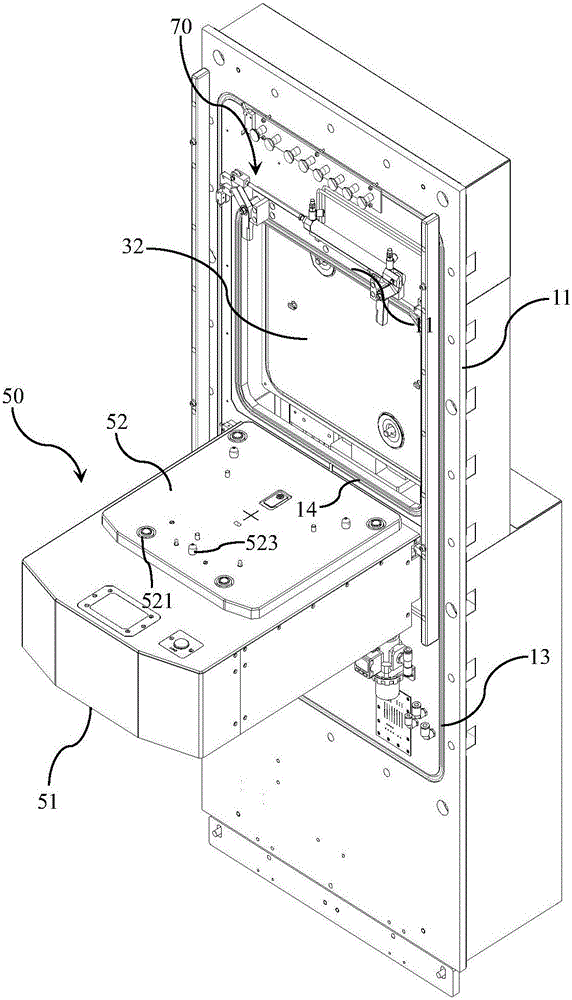

[0035] Such as figure 2 , image 3 , Figure 4 As shown, the fully enclosed SMIF system 100 includes: a mounting plate 11 , a lifting part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com