an array substrate

An array substrate and glass plate technology, applied in the field of liquid crystal display, can solve problems such as uneven panel gaps, poor display, and the inability of photoreactive gap control materials to play an effective supporting role, so as to improve binding packaging and avoid display problems. Bad, effect to improve display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

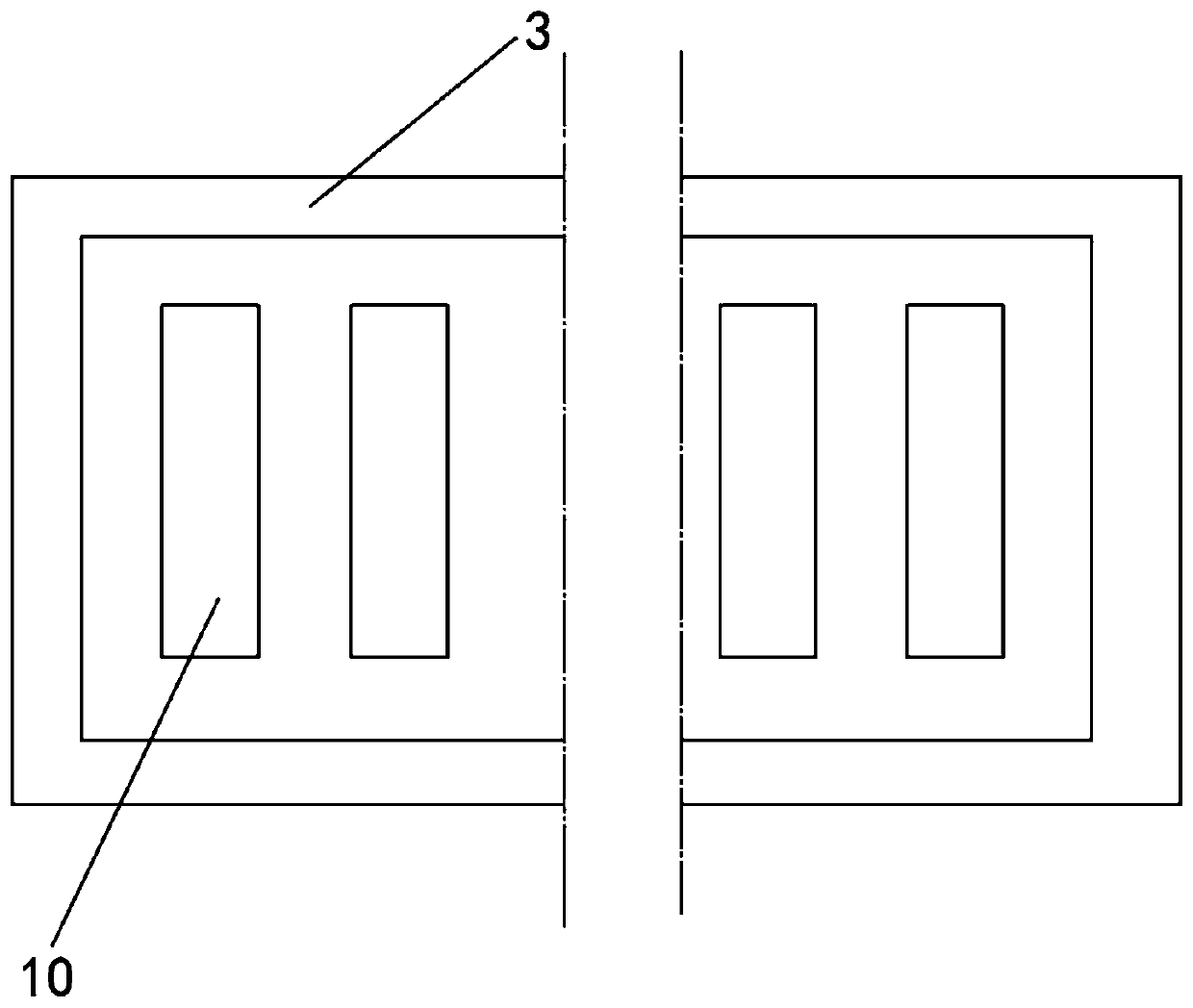

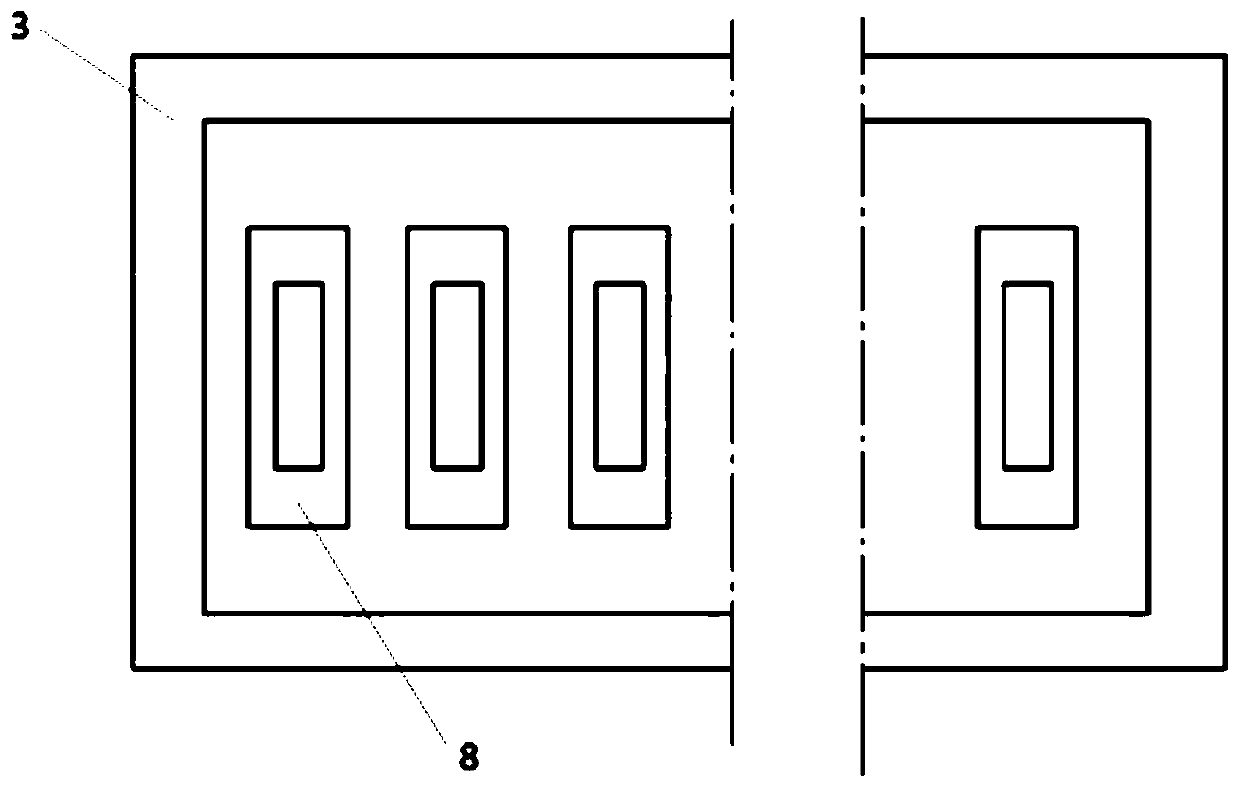

[0028] The present invention relates to array substrates, such as image 3 As shown, an array substrate includes a first flat layer 31 arranged around a glass plate 1 and a plurality of mutually parallel COG / FOG plates 8 arranged in the center of the glass plate 1 .

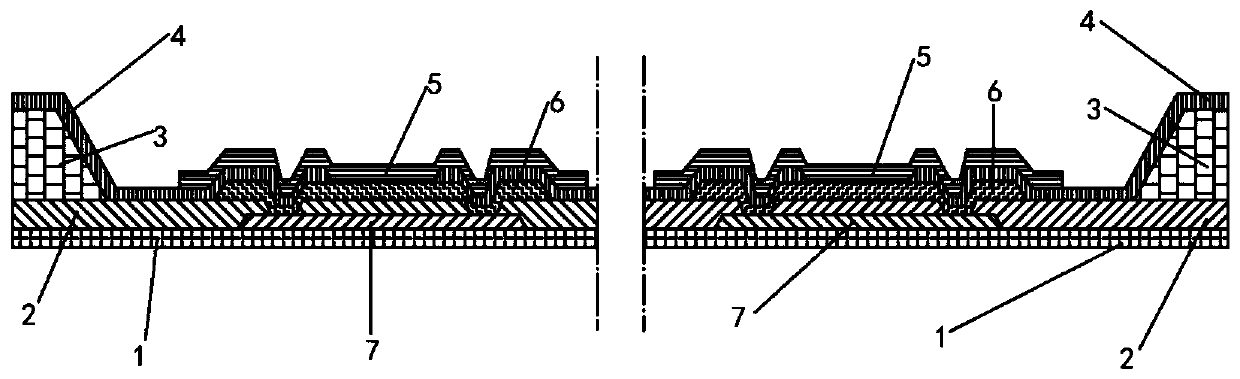

[0029] Such as Figure 4 As shown, the COG / FOG board 8 includes: a top-layer transparent electrode 5, a passivation layer 4, a second flat layer 32, a second metal layer 6, and a gate electrode arranged sequentially from top to bottom on the glass plate 1. The insulating layer 2 and the first metal layer 7. Wherein, the second flat layer 32 is disposed at the center of the array substrate 8 . The passivation layer 4 completely covers the second flat layer 32 and the first flat layer 31 .

[0030] The gate insulating layer 2 disposed on the first metal layer 7 is etched in the area around the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com