Electrode plate porosity measurement and calculation method

A calculation method and porosity technology, applied in the field of pole piece porosity testing, can solve the problems of reduced cycle life, poor integrity of battery pole piece conductive network, health hazards of test personnel, etc., and achieve the effect of overcoming the high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

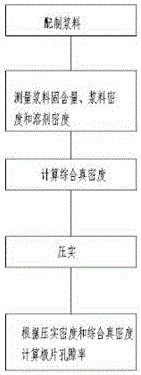

[0021] Such as figure 1 As shown, a method for measuring and calculating the porosity of a pole piece includes the following steps: firstly, the slurry is prepared by using the main powder material, conductive agent, glue and solvent; measuring the density of the slurry and the solid content of the slurry; Density, slurry solid content and the density of the selected solvent are used to calculate the comprehensive true density; according to the compaction density required by the pole piece, the above slurry is used to coat the surface of the pole piece, and the surface of the pole piece is compacted; The compacted density and the integrated true density are used to calculate the porosity of the pole piece.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com