A Power Compensation Method for Electric Workover Rig

An electric workover rig and power calculation technology, applied in electric vehicles, current collectors, electrical components, etc., can solve the problems of difficulty in determining the power of the super capacitor group and the connection method within the group, and no power calculation and distribution method is proposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

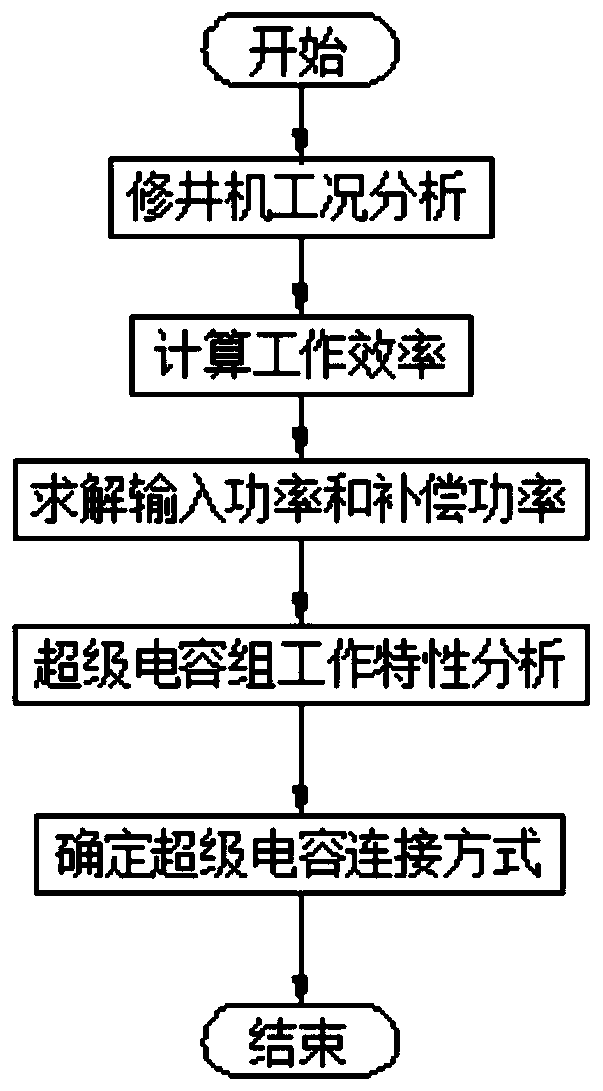

[0068] The present invention will be further described below in conjunction with accompanying drawing:

[0069] 1) Set the target working condition requirements of the workover rig, analyze and determine the relevant parameters

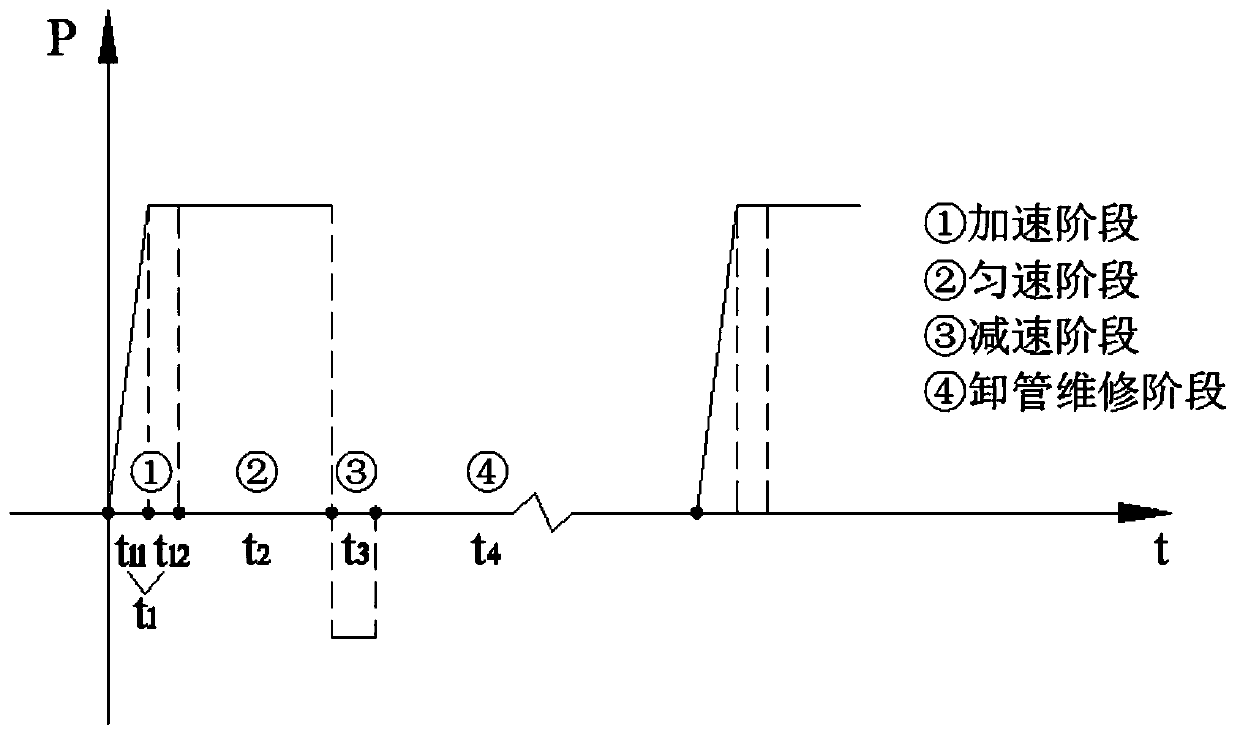

[0070] see image 3 , the single-cycle operation of the workover rig can be divided into four stages, namely, the acceleration stage, the constant speed stage, the deceleration stage, and the pipe unloading maintenance stage. Power acceleration, according to the formula (2) to calculate the required power, get At the same time, in order to ensure work efficiency, the extubation time should be less than 20-40s. Therefore,

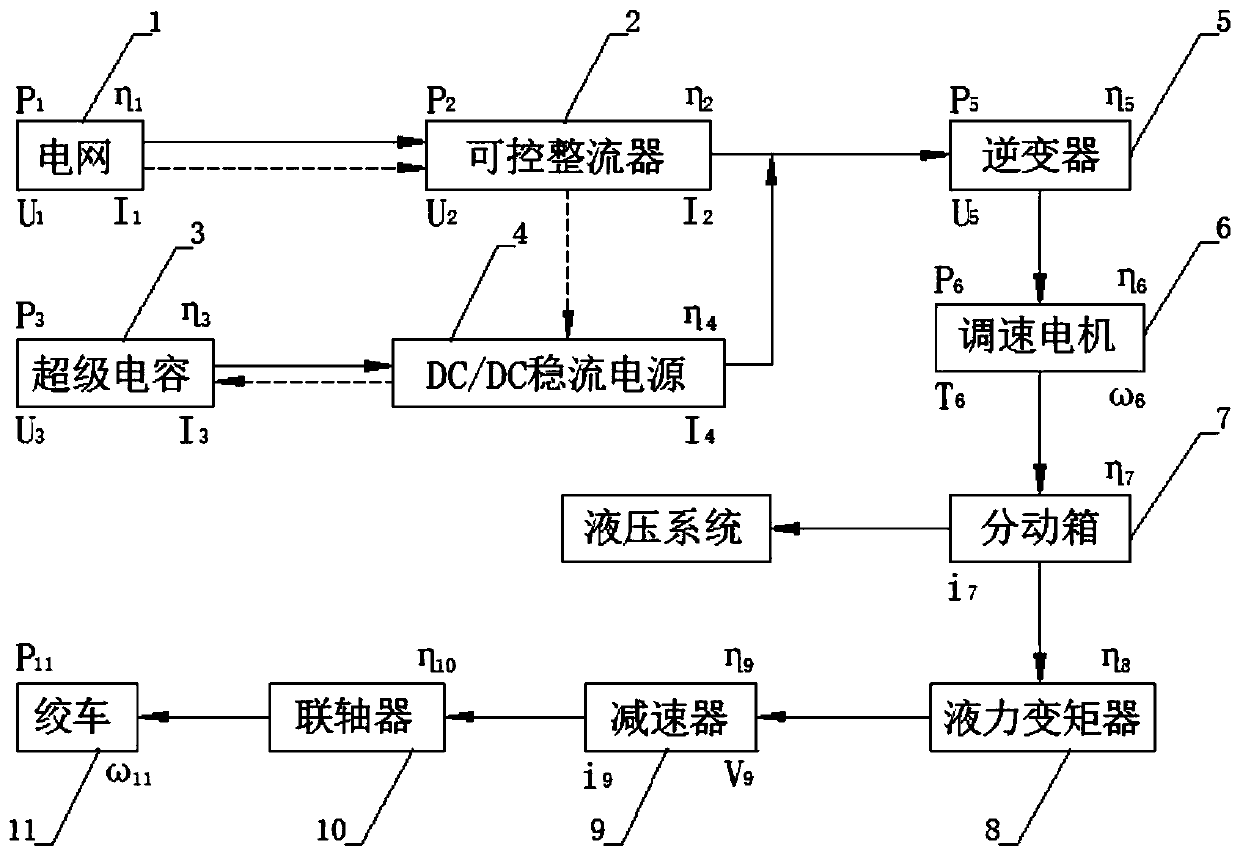

[0071] see figure 2 , according to the formulas (3) and (4), it can be known that the torque required by the drawworks to lift the well pipe is Among them, T M is the required torque in the acceleration stage, and Te is the required torque in the constant speed stage. At the same time, due to the heavy weight of the well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com