Cable ladder

A cable ladder frame and cable technology, applied in the direction of pipe support, electrical components, rod connection, etc., can solve the problems that it is difficult to change the structure, the assembly operation is difficult, etc., and achieve the effect of easy operation and strong clamping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

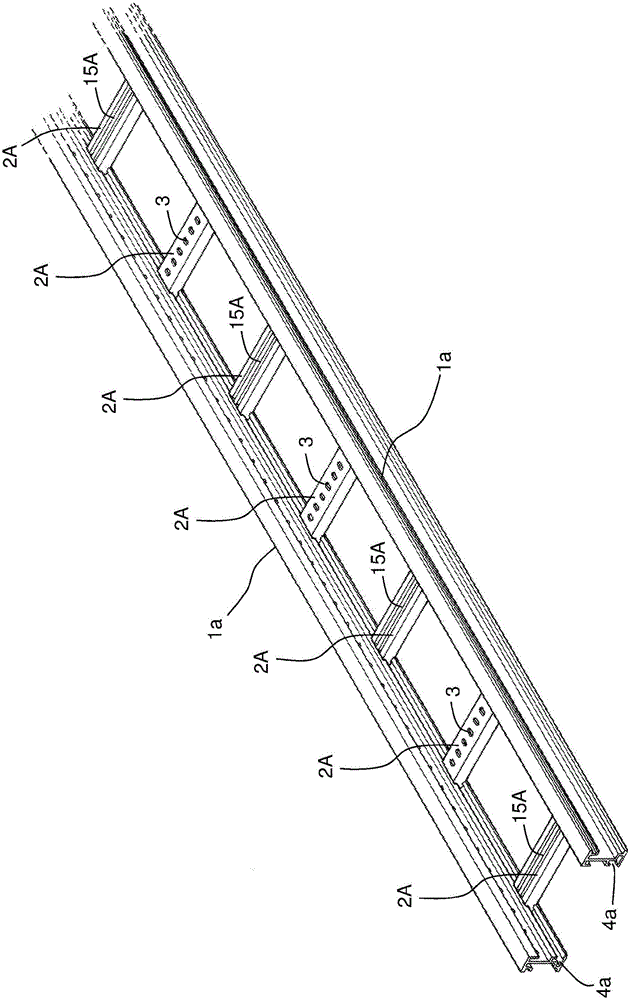

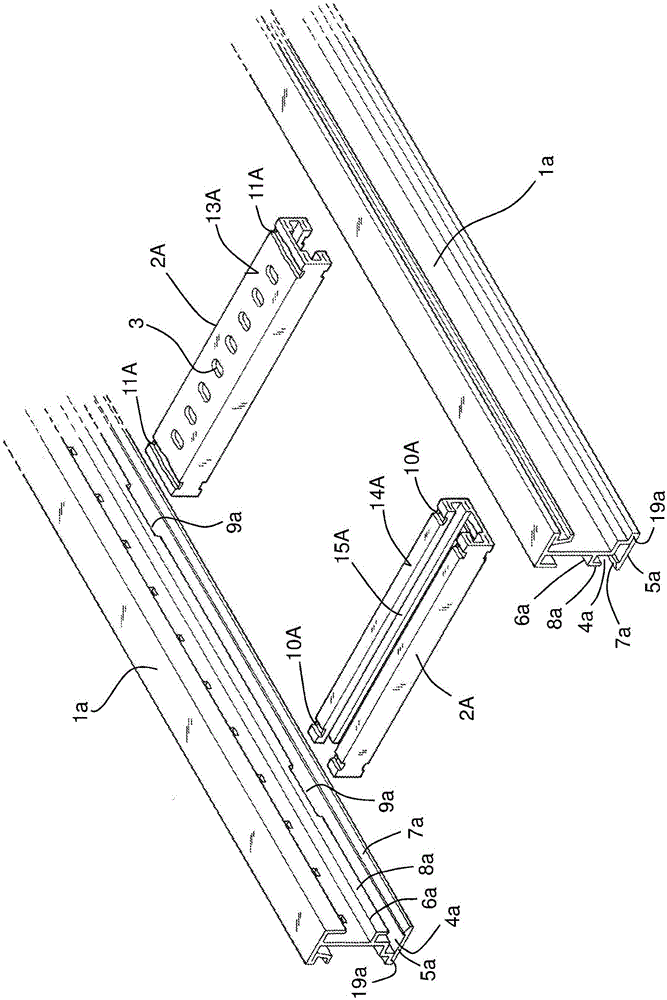

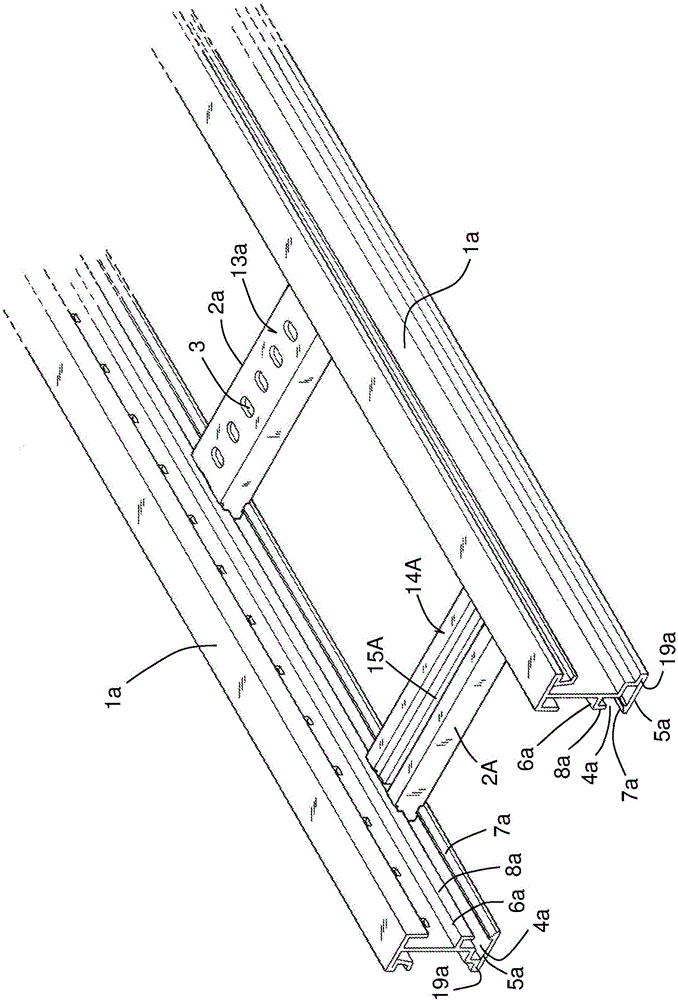

[0043] Figure 1-4 A first embodiment of a cable ladder frame according to the invention is shown. Such as figure 1 As shown, the cable ladder frame is formed by two parallel side rails 1a attached to each other by a plurality of parallel cross bars 2A regularly spaced from each other. The two side rails 1a are identical and arranged symmetrically with respect to each other. Each side rail consists of an extruded profile made of polymer material. An electrical insulating material with a surface resistivity greater than 100 MΩ, such as PVC (polyvinyl chloride), etc., is preferred as the polymer material. All crossbars 2A are identical and likewise consist of an extruded profile made of the same material as the side rails 1a. Similar to prior art cable ladders, the combination of cross bars 2A forms a discontinuous support surface for the cables on which the cables held by the cable ladder are laid. The installer can use different fastening means (not shown) to fix the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com