Green belt trimmer

A green belt, trimmer technology, applied in agricultural machinery and implements, cutting tools, cutting equipment and other directions, can solve the problems of easy fatigue, low work efficiency, psoas muscle and wrist injury, etc., and achieves simple structure and flexible use of the device. Convenient and comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

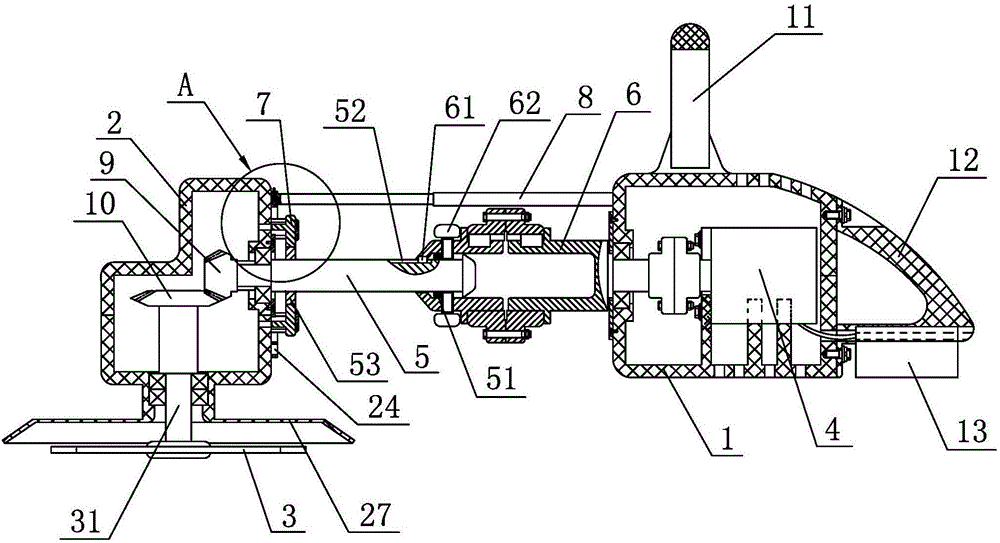

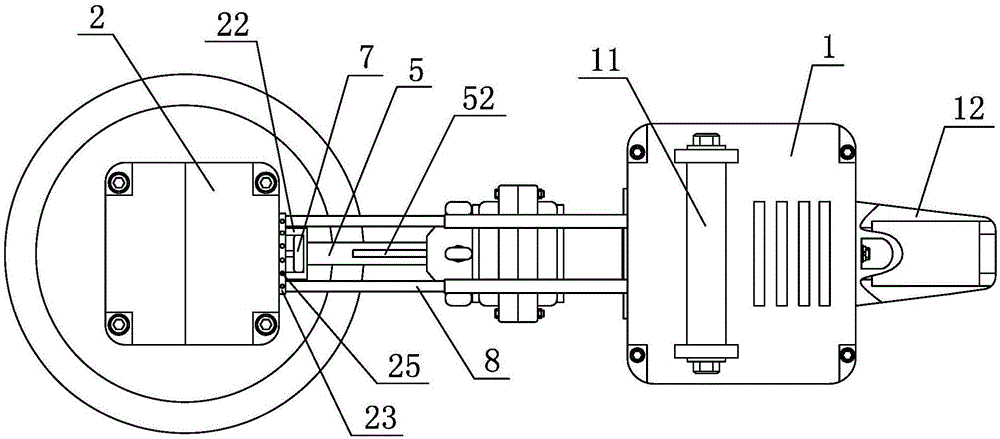

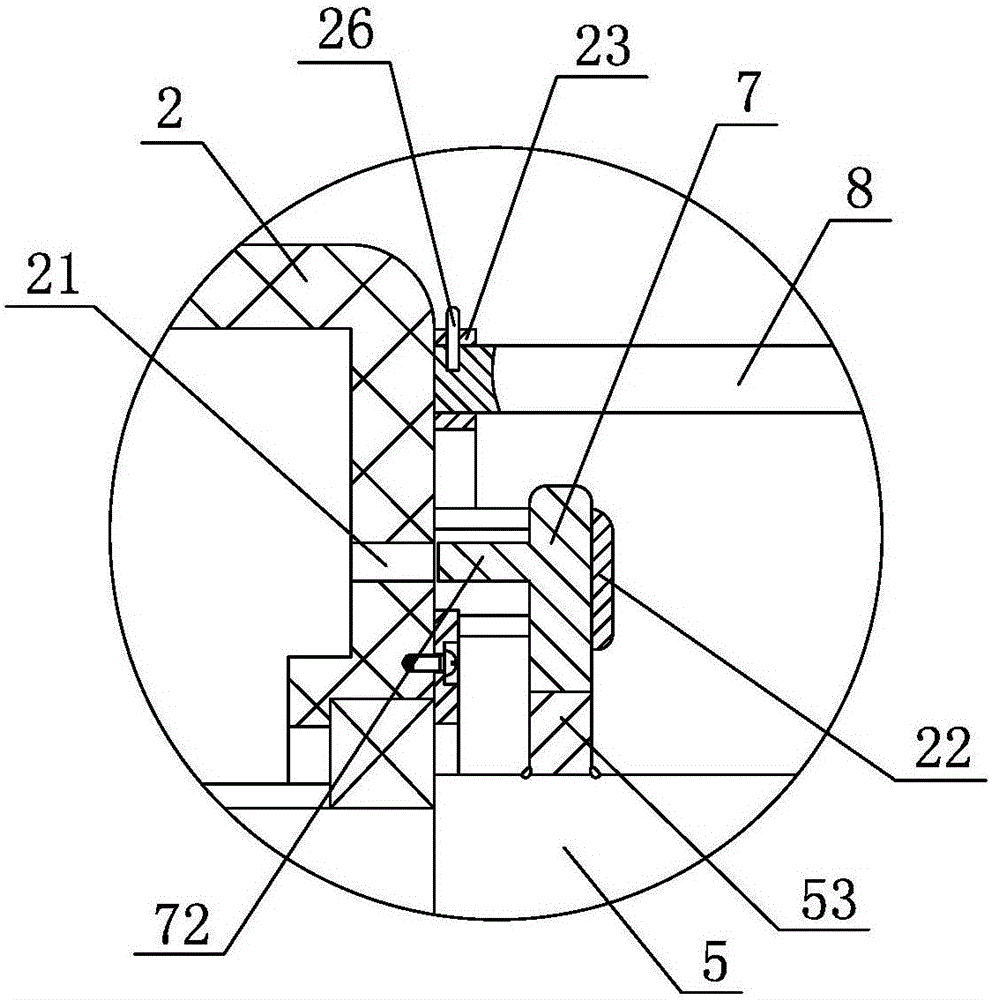

[0020] Embodiment 1: As shown in the figure, a green belt trimmer includes a main housing 1, an auxiliary housing 2, a blade 3 and a blade rotation drive mechanism, the main housing 1 and the auxiliary housing 2 are separated from each other, and the main housing 1 is fixedly provided with a handle 11, and the rear end of the main housing 1 is fixedly provided with a handle 12. The blade rotation drive mechanism includes a motor 4, a drive shaft 5 and a blade shaft 31, and the motor 4 is fixedly arranged on the main housing 1. Among them, the drive shaft 5 is provided with an axial telescopic mechanism, the axial telescopic mechanism includes a hollow shaft 6, the hollow shaft 6 is axially connected with the main casing 1, the hollow shaft 6 is coaxially fixedly connected with the output shaft of the motor 4, and the drive shaft The rear end of 5 extends coaxially into the hollow shaft 6 and slides axially with the hollow shaft 6. A centering ring 51 is arranged between the dri...

Embodiment 2

[0021] Embodiment 2: As shown in the figure, a green belt trimmer includes a main housing 1, an auxiliary housing 2, a blade 3 and a blade rotation drive mechanism, the main housing 1 and the auxiliary housing 2 are separated from each other, and the main housing 1 is fixedly provided with a handle 11, and the rear end of the main housing 1 is fixedly provided with a handle 12. The blade rotation drive mechanism includes a motor 4, a drive shaft 5 and a blade shaft 31, and the motor 4 is fixedly arranged on the main housing 1. Among them, the driving shaft 5 is axially connected with the main housing 1 and the auxiliary housing 2 respectively, the rear end of the driving shaft 5 is coaxially fixedly connected with the output shaft of the motor 4, and a rotating shaft is arranged between the auxiliary housing 2 and the driving shaft 5. The clutch mechanism, the rotating clutch mechanism includes a clutch block 7, the clutch block 7 is sleeved on the drive shaft 5, the drive shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com