Standard pig feed trough

A feeding trough and standard technology, applied in animal feeding devices, animal drinking water devices, applications, etc., can solve the problems of inability to standardize the process of feeding and drinking water, the inability to standardize the production of pig feeding troughs, and the inability to meet the needs of feeding and drinking water, etc., to achieve The effect of process standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

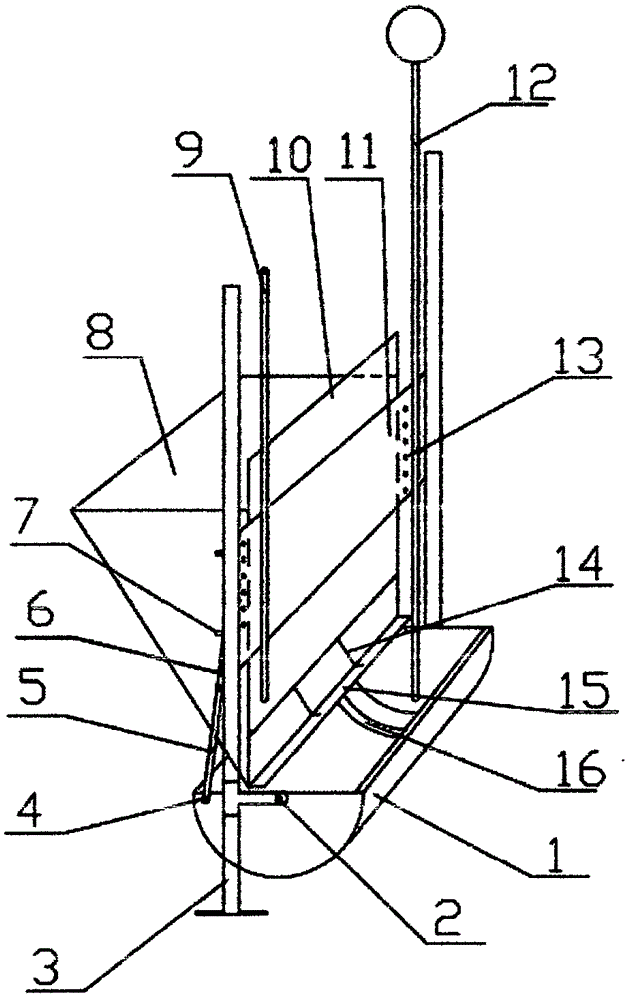

[0016] A standard pig trough is divided into four parts: bracket, storage box 8, drinker and feed trough 1. The storage box 8, the feeding trough 1 and the drinking fountain are all fixed on the bracket, and the storage box 8 and the feeding trough 1 are separated. Both the feed in the storage box 8 and the water in the drinking fountain can fall into the feeding trough 1. To achieve the purpose of eating and drinking water.

Embodiment 2

[0018] The bracket is composed of a bracket column 3 and a bracket fixing steel plate 11 between the two columns. The bracket is fixed on the floor of the pigsty.

Embodiment 3

[0020] The storage box is composed of three fixed plates, a movable plate 10, a toggle lever 14 and a feeding edge 15, and is connected to the bracket fixing steel plate 11 through a second round hole 13 and can move up and down. When the pig eats, the height of the feeding opening is adjusted by the movable plate 10, and the pig's mouth moves the toggle lever 14 to make the feed fall on the feeding edge 15 or into the feeding trough 1 for feeding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com